Types of conveyor belt

Tuesday March-15 2022 13:35:39

Conveyor belts play an important role in industrial transmission and transportation. Let me introduce the ten types of conveyor belts:

1. Ordinary conveyor belt

This kind of conveyor belt is suitable for conveying bulk, granular and powdery materials without special corrosion at room temperature under normal conditions. The strength layer is a good heavy-duty cotton canvas or cotton, polyester and cotton canvas. Compared with ordinary cotton core conveyor belt, the conveyor belt has the advantages of high strength, good elasticity, impact resistance, light weight, and good groove forming ability. It can effectively reduce costs and realize high-speed, large-span and long-distance transportation.

2. PVC conveyor belt

PVC conveyor belt products can be divided into tobacco industry conveyor belts, logistics industry conveyor belts, packaging industry conveyor belts, etc. The temperature range can be divided into: cold-resistant conveyor belts (above minus 40°) normal temperature conveyor belts (minus 10° to 80°), PVC conveyor belt has good elasticity and is not easy to deform. Use high-strength cotton, nylon, polyester canvas as the belt core, and use natural rubber non-polluting compounding agent to make white or light color, non-polluting, and will not affect food hygiene and odor cover.

3. Heat-resistant conveyor belt

Heat-resistant conveyor belts are mainly used to convey high-temperature materials, such as sinter, hot coke, cement clinker, hot castings, etc.

4. Acid and alkali resistant conveyor belt

It is suitable for working environments in contact with acid and alkali, such as phosphate fertilizer manufacturing and seawater drying.

5. Whole core flame retardant conveyor belt

It has the characteristics of high strength, large capacity and balanced transportation. At the same time, the product has good flame retardant, antistatic, impact resistance, wear resistance, corrosion resistance and other properties. This product is mainly suitable for underground transportation of coal mines, and can also be used for material transportation in metallurgy and chemical industries. The whole core flame retardant conveyor belt can be divided into PVC type and PVG type.

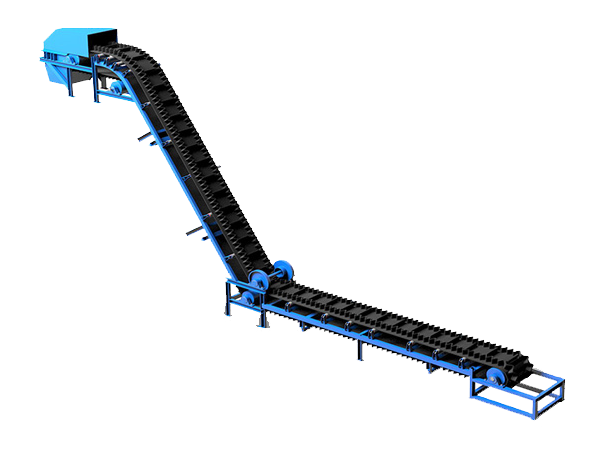

6. Pattern conveyor belt

The inclination angle is 0-45o to prevent the material from sliding down and improve the conveying capacity. According to the different covering performance, it is divided into ordinary, oil resistance, acid and alkali resistance, heat resistance, etc.

7. Rubber conveyor belt

The rubber lifting belt is made up of multiple layers of glued fabrics, and generally there should be covering glue outside the belt core.

8. Oil resistant conveyor belt

The cover rubber adopts nitrile rubber with high acrylonitrile content as the main material.

9. Rubber water stop

Generally used in large concrete structures, such as dams, reservoirs, basements, etc.

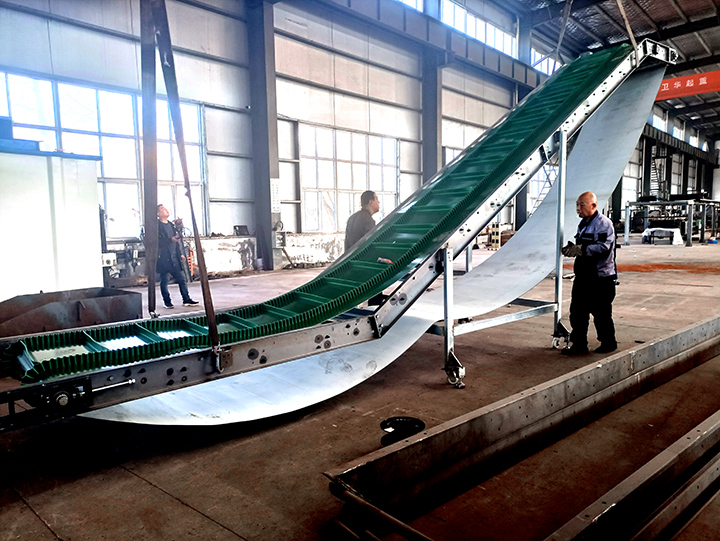

10. Corrugated sidewall conveyor belt

The characteristic of the structure is to replace the ordinary conveyor belt with a corrugated sidewall conveyor belt (which can be referred to as "sidewall belt" for short).