Urea bucket elevator

Wednesday February-12 2025 16:17:43

Urea bucket elevator is a kind of equipment specially used for conveying urea granules vertically or obliquely, mainly used for conveying granular or powdery materials such as urea, fertilizer, grain, etc. It lifts urea granules from a low place to a high place through a hopper fixed on a traction belt or chain, and unloads at a designated position, thereby realizing continuous conveying of materials. It has the characteristics of simple structure, reliable operation, large conveying capacity, etc., and is widely used in fertilizer production lines, warehousing logistics systems and other granular material conveying systems.

Video of urea bucket elevator

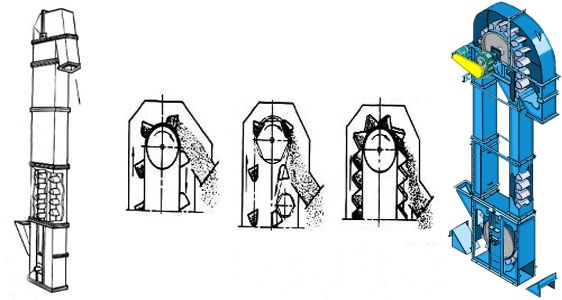

What is urea bucket elevator theory?

The hopper scoops up the urea from the storage below, and is lifted to the top by the conveyor belt or chain. After passing the top wheel, it turns downward and pours the urea into the receiving tank. The motor drives the sprocket to rotate, and the hopper on the sprocket moves up and down with the chain. When the hopper is at the lowest point, it is automatically filled with materials; when the hopper rises to the highest point, it is automatically unloaded. In this way, urea particles are continuously lifted from the bottom to the top.

Applicable materials for urea bucket elevator

1. Powdered materials: such as cement, raw materials, coal powder, etc. These materials have small particle size and good fluidity, which are similar to the fine powder part in urea particles. Bucket elevator can achieve efficient lifting of them through appropriate bucket design and conveying speed.

2. Granular materials: including but not limited to grains, beans, plastic particles, etc. Urea is mostly granular, and has certain similarities with these granular materials in shape and fluidity. Bucket elevator can well adapt to the lifting operation of such materials.

3. Small block materials: such as small pieces of limestone, coal, crushed ore, etc., as long as their size and weight are within the load range of the bucket elevator, and the hardness, abrasiveness and other characteristics of the material will not cause excessive wear to the bucket and conveying parts of the elevator, urea bucket elevator can also be used for lifting.

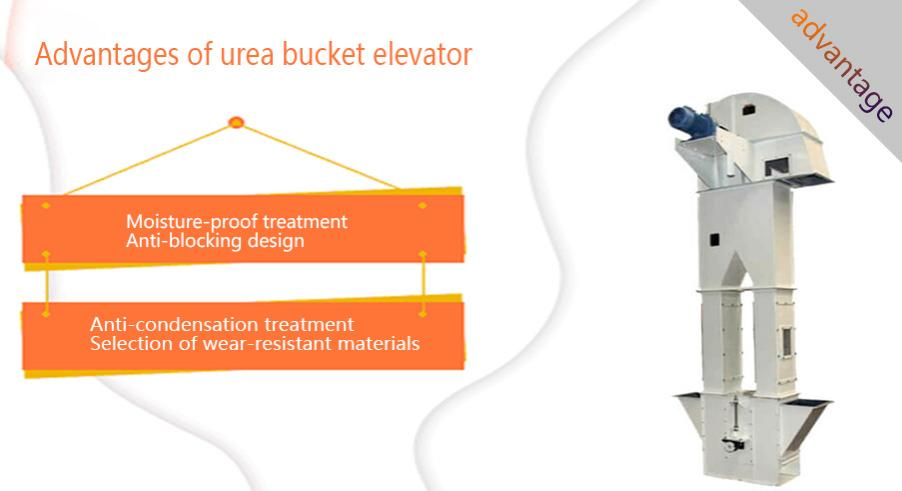

Advantages of urea bucket elevator

1. Moisture-proof treatment: Urea is prone to moisture absorption and agglomeration, which is a common problem, especially in humid environments. In order to solve this problem, urea bucket elevators usually consider moisture-proof measures during design, such as adopting sealing design, installing moisture-proof covers, etc., to reduce the possibility of urea moisture absorption and agglomeration.

2. Anti-blocking design: Urea granules are prone to blockage, which is another common problem that will affect the normal operation of the elevator. In order to solve this problem, urea bucket elevators usually adopt specially designed bucket shapes and bucket spacing to reduce the possibility of granule blockage and ensure smooth material transportation.

3. Anti-condensation treatment: In low temperature environments, urea is prone to condensation, resulting in granule adhesion, blockage and other problems. In order to solve this problem, urea bucket elevators may take heating measures or insulation measures to keep the material at a suitable temperature for transportation.

4.Selection of wear-resistant materials: Since urea granules have a certain hardness, they are prone to wear on the equipment. In order to extend the service life of the equipment, urea bucket elevators usually use wear-resistant materials to manufacture key components, such as buckets, conveying chains, etc., to reduce wear.

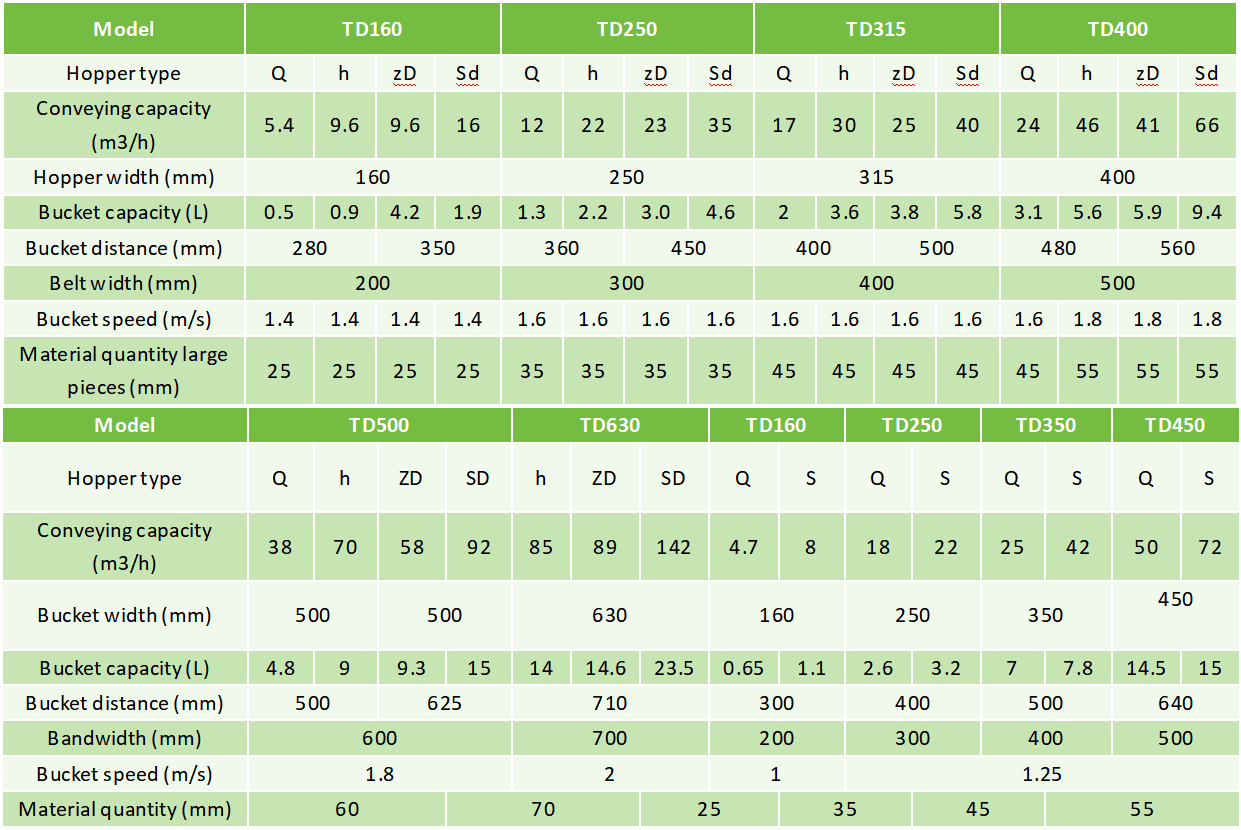

Urea bucket elevator model parameter table

Application of urea bucket elevator

Urea bucket elevator is mainly used in urea production enterprises to lift urea from the production link to storage tanks, packaging stations, etc.; it is also used in the field of fertilizer storage and logistics to lift urea from the warehouse floor to high shelves or transport vehicles; in large-scale urea storage and distribution centers in the agricultural field, it can be used to lift urea to silos or conveying equipment at different heights for quantitative distribution and transportation.

1. Application in the production process: The raw materials for urea production usually need to go through processes such as crushing and mixing. The urea bucket elevator can transport these raw materials to the reaction tower or storage silo. The produced urea granules need to be transported to the packaging workshop or storage silo.

2. Application in agriculture: The urea bucket elevator can transport urea from the storage silo to the batching system and mix it with other fertilizers to make compound fertilizer. The prepared fertilizer needs to be packaged, and the urea bucket elevator can transport the fertilizer to the packaging machine.

3. Application in industry: The urea bucket elevator can transport urea to the reactor or storage tank. Urea can be used for sewage treatment or transported to the reaction tank.

Urea bucket elevator plays an important role in the production and treatment of urea. Choosing the right equipment and maintaining it well can significantly improve production efficiency and equipment life.