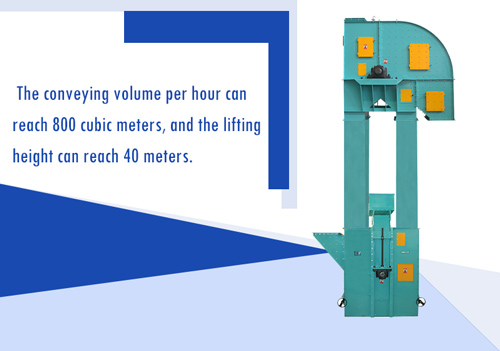

Vertical Corn and Wheat Bucket Elevator

Saturday July-22 2023 16:28:57

Introduction

Vertical Corn and Wheat Bucket Elevator is a common material conveying equipment, which is mainly used to transport granular or powdery materials vertically from one place to another, and is widely used in fields such as farmland, mine, chemical industry, construction and so on.

Structures

The vertical corn and wheat bucket elevator consists of a casing, a traction part (conveyor chain), a hopper, a driving wheel (head wheel), a redirection wheel (tail wheel), a tensioning device, a guiding device, a feeding port (feeding port) and a discharging port Port (discharge port) and other parts.

Housing: Housing: Built-in transmission and brakes.

Traction: It is a plate sleeve roller chain. The single chain is fixed on the rear wall of the hopper. The double chain is connected to both sides of the hopper. When the width of the hopper is 160~250mm, the single chain is used. chain.

Hopper: Cylindrical hopper: The deep hopper and the mouth of the hopper are inclined at 65°, and the depth is large. It is used for drying, good fluidity and well-scattered granular materials.

Shallow hopper: The mouth is inclined at 45° and the depth is small, for wet and fluid granular materials.

1) Deep hopper: generally used to dry materials with good fluidity.

2) Triangular hopper: The material is generally directional self-flow discharge.

3) Sharp-angled bucket: its side wall extends outside the bottom plate and becomes a rib. When discharging, the material can be unloaded along the groove formed by the ribs and the bottom plate of a bucket, which is suitable for viscous and heavy block materials transport.

Sprockets: Sprockets are used to mesh with precisely pitched blocks on link links or cables, and are solid or spoked gears that mesh with roller chains to transmit motion.

Working Principle

The working principle of the vertical corn and wheat bucket elevator is to drive the transmission device through the motor to make the felt belt in the elevator move. When the material enters the elevator from the feed port, the bucket will load the material onto the felt belt, and with the movement of the felt belt, the material is lifted to the required height and unloaded at the discharge port. During the whole process, the elevator keeps running continuously to realize the fast and efficient conveying of materials.

Advantages

1. Adopt inflow feeding, inductive discharging and large-capacity hopper intensive arrangement. There is almost no material returning and digging phenomenon when the material is lifted.

2. It is used for vertical conveying of various forms of bulk materials, which can cope with the conveying of high temperature, irregular and fragile products, with a small footprint.

3. The conveying volume per hour can reach 800 cubic meters, and the lifting height can reach 40 meters.

4. The operation reliability is good, and the trouble-free time exceeds 20,000 hours.

5. The casing is tightly sealed to ensure that there is no dust pollution in the process of lifting materials.

Technical parameters

Applications

The vertical corn and wheat bucket elevator is suitable for a series of scenarios, including but not limited to the following aspects:

1. Farmland: It is used for harvesting, storage and transportation of crops such as corn and wheat.

2. Mine: It is used for lifting and conveying materials in coal mines, gold mines and other mines.

3. Chemical industry: It is used for storage and transportation of raw materials in the chemical industry.

4. Construction: raw material delivery and storage for construction sites.

Why choose Vertical Bucket Elevator?

Although both screw conveyors and belt conveyors can be designed to be inclined for the lifting and conveying of bulk materials, they require a certain amount of floor space per height unit raised, and they face excessively large angles of material conveying. There will be difficulties in lifting and material scattering.

Therefore, Vertical Bucket Elevator is the best lifting solution when space is limited.

The vertical lifting section of the Vertical Bucket Elevator is designed on its base. As long as the space can accommodate its base, the Vertical Bucket Elevator can be used to transport and lift materials.

In addition, the hopper holding and sealing design of Vertical Bucket Elevator ensures that the material will not be damaged or polluted.