What are the parts of a rubber conveyor belt

Wednesday January-08 2025 11:19:46

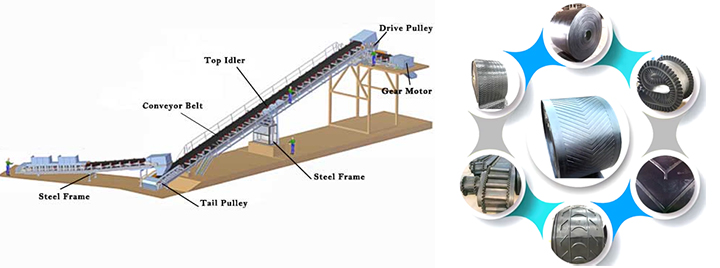

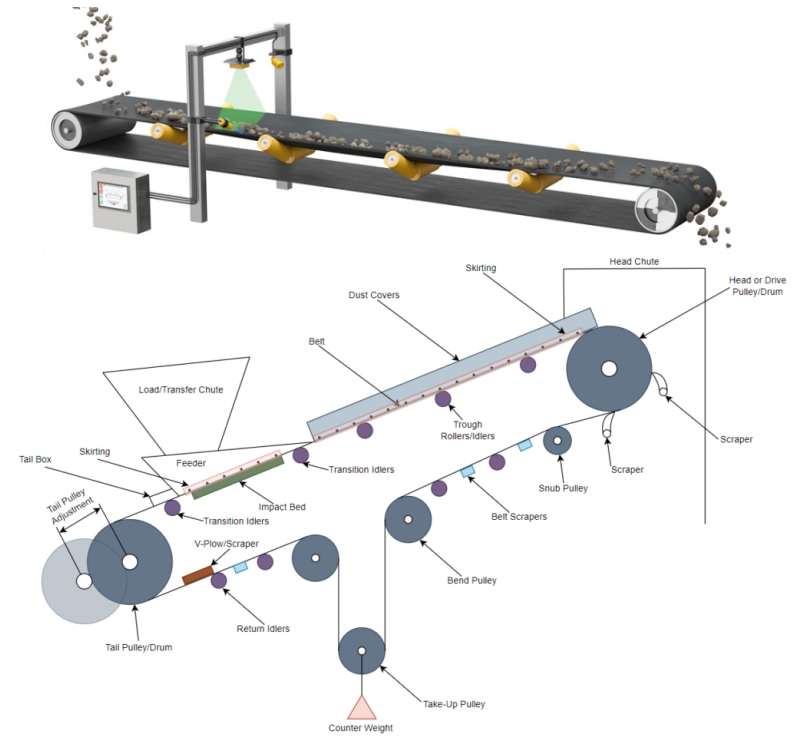

Rubber conveyor belt is a common conveying equipment and is widely used in material conveying systems in various industries. It consists of multiple parts, each with specific functions and roles. Several main parts of rubber conveyor belts will be introduced in detail below.

1. Rubber surface layer: The rubber surface layer is the top layer of the rubber conveyor belt and is in direct contact with the material. It is usually made of wear-resistant rubber or other synthetic materials and has good wear resistance and cut resistance. The design of the rubber surface can be adjusted according to specific application needs, for example, grooves or patterns can be added to provide extra grip or anti-slip effect.

| Belt type | Features | Applicable materials | Typical application scenarios |

| Ordinary rubber conveyor belt | Simple structure, low price, average wear resistance. | General industrial products, granular materials | Mines, building materials, ports, etc. |

| Heat-resistant rubber conveyor belt | Good high temperature resistance, suitable for conveying high temperature materials. | Hot coal, slag, clinker, etc. | Metallurgy, building materials industry |

| Acid-resistant and alkali-resistant rubber conveyor belt | Acid and alkali resistance, suitable for conveying corrosive materials. | Acidic and alkaline materials, chemicals | Chemical industry, food industry |

| Oil-resistant rubber conveyor belt | Oil resistance, suitable for conveying grease materials. | Grease, asphalt, etc. | Petrochemical industry |

| Cold-resistant rubber conveyor belt | Low temperature resistance, suitable for conveying materials in low temperature environment. | Frozen food, ice, etc. | Food refrigeration, ice making industry |

| Patterned rubber conveyor belt | The surface has patterns to increase friction and prevent materials from slipping. | Small particles, loose materials | Coal, mining industry |

2. Skeleton layer: The skeleton layer is the main support structure of the rubber conveyor belt, usually composed of multiple layers of fiber fabric or synthetic fiber cord. These fiber layers play a key role in the strength and tensile resistance of conveyor belts. Common frame materials include polyester, nylon, and cotton fibers. The selection of the skeleton layer depends on the required strength, wear resistance and tensile resistance of the conveyor belt.

3. Adhesive layer: The adhesive layer is located between the adhesive surface layer and the skeleton layer and is used to bond them together. The adhesive layer is usually made of special adhesive or glue with good adhesive properties and durability to ensure the stability and reliability of the conveyor belt.

4. Bottom layer: The bottom layer is the bottom layer of the rubber conveyor belt, which is usually in contact with the rollers of the conveyor equipment. The bottom layer is also designed with wear-resistant rubber or other synthetic materials to increase the wear resistance and cut resistance of the conveyor belt. The bottom layer can also have special textures or grooves to provide better grip and anti-slip effects.

In addition to the above main parts, rubber conveyor belts may also include other ancillary components, such as edge protection belts, transverse reinforcement belts and connectors, etc., to increase the stability and service life of the conveyor belt.

To sum up, the rubber conveyor belt consists of several main parts such as rubber surface layer, skeleton layer, adhesive layer and bottom layer. Each part has specific functions and characteristics that together ensure the conveyor belt's wear resistance, slip resistance and tensile strength. Proper design and selection of these parts is critical to the performance and service life of the conveyor belt.

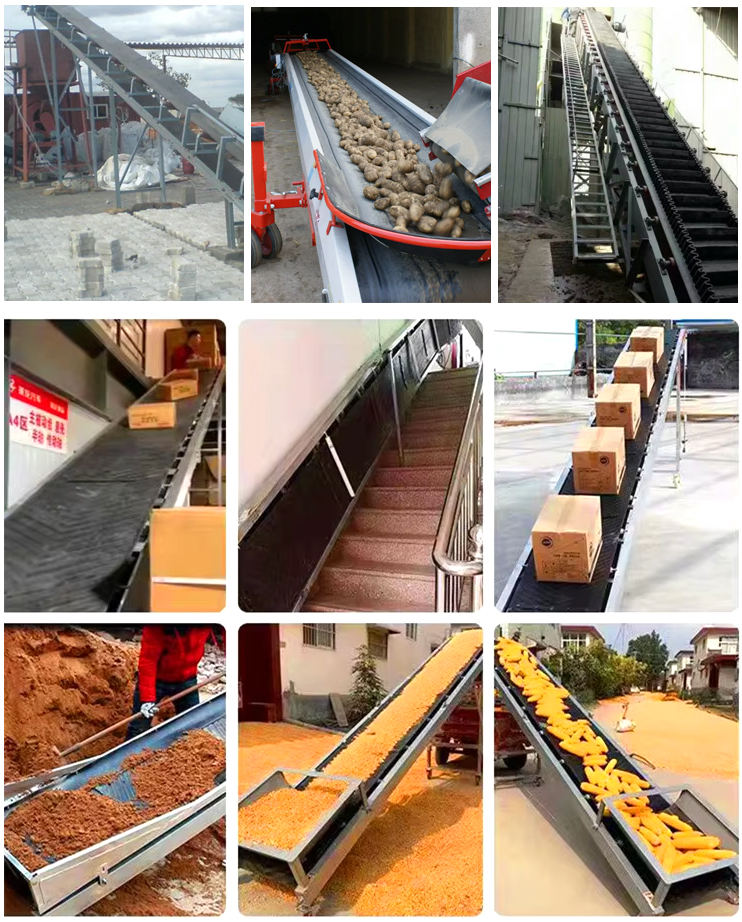

Rubber conveyor belt is made of rubber material and has good wear resistance and corrosion resistance. It is suitable for mines, construction sites, ports, chemical industry and other industries. It is used to transport various materials such as ore, building materials, grain, chemical products, etc., to improve production efficiency and reduce transportation costs.