What is a tube screw conveyor?

Wednesday February-28 2024 14:00:39

Tube screw conveyor, also known as a tubular screw conveyor, is a type of mechanical conveying system used to transport bulk materials in a closed and enclosed cylindrical tube. It consists of a rotating screw or auger inside the tube, which moves materials along the length of the conveyor.

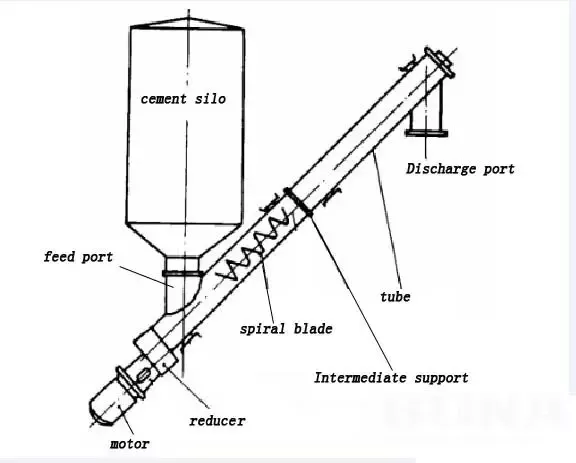

The tube screw conveyor typically comprises the following components:

Tube/Casing: It is a cylindrical structure that encloses the screw and contains the material being transported. The tube is usually made of steel or another durable material and can vary in diameter and length depending on the application.

Screw/Auger: The screw is the central component of the tube screw conveyor. It is a helical-shaped structure that rotates within the tube to move the material. The screw is typically made of steel and is designed with flights or paddles that push the material forward as the screw rotates. The pitch and diameter of the screw determine the conveying capacity and speed.

Inlet and Outlet: The tube screw conveyor is equipped with an inlet at one end to allow the material to enter the conveyor system. The outlet is located at the other end to discharge the material.

Drive System: The screw is driven by a motor and gearbox arrangement, which provides the rotational power to move the material. The motor can be electric, hydraulic, or pneumatic, depending on the specific application and requirements.

Tube screw conveyors are widely used in various industries for handling bulk materials such as powders, granules, flakes, and pellets. They offer several advantages, including:

Versatility: Tube screw conveyors can handle a wide range of materials, including both free-flowing and non-free-flowing substances.

Contained Conveying: The enclosed tube design of the conveyor prevents material spillage, dust generation, and contamination, making it suitable for applications where hygiene and cleanliness are crucial.

Gentle Material Handling: The screw flight design and controlled rotational speed of the screw ensure gentle handling of materials, minimizing degradation and preserving the integrity of the conveyed product.

Flexibility in Layout: Tube screw conveyors can be installed horizontally, inclined, or vertically, allowing for flexible layout configurations to suit different space constraints and process requirements.

Customization: Tube screw conveyors can be customized with various options such as different tube diameters, screw designs, and additional features like hoppers, covers, and sensors to meet specific application needs.

Overall, tube screw conveyors provide an efficient and reliable method of conveying bulk materials in a contained and controlled manner, making them a popular choice in many industries.