What system is present in a conveyor belt

Wednesday November-15 2023 15:28:16

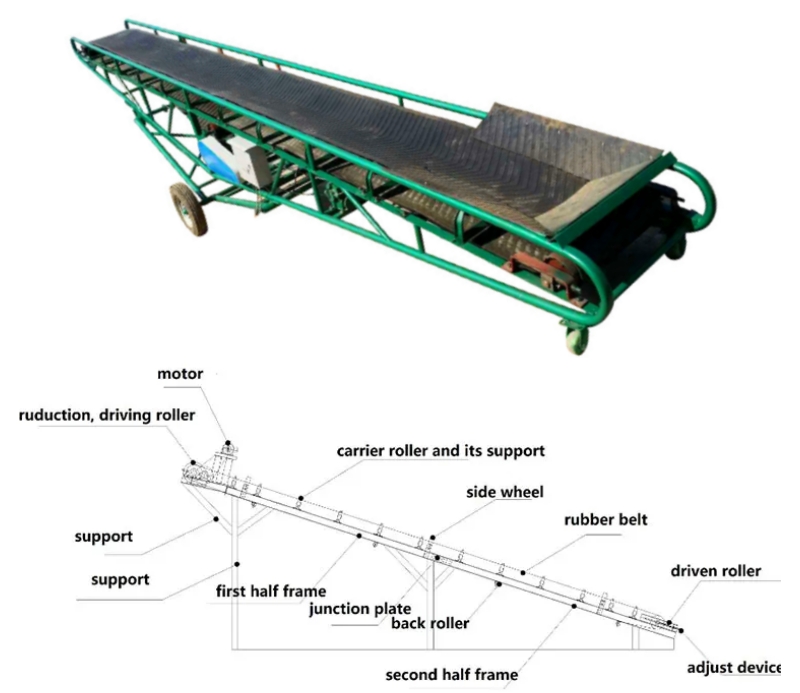

A conveyor belt is a device used to automatically transport items or materials. It is an important part of the belt conveyor system and is widely used in industrial production and logistics fields. Conveyor systems are made up of several key components to ensure smooth material transfer and efficient operations. Here are some important components and systems commonly found in conveyor belt systems.

Conveyor Belts: Conveyor belts are the core part of a conveyor belt system and are made of flexible materials such as rubber, polymer, or metal. It forms a continuous belt-like structure for carrying and transporting items. Conveyor belts are usually supported by drive rollers and tensioning rollers, with movement via an electric drive system.

Drive System: The drive system provides the power to enable the conveyor belt to operate. It usually consists of an electric motor, reducer and transmission device. The drive system converts electrical energy into mechanical power to drive the movement of the conveyor belt.

Tensioning system: The tensioning system is used to maintain the tension of the conveyor belt to ensure that the conveyor belt maintains proper tension during operation. It usually includes components such as tensioning rollers, tensioning devices and tensioning wheels. By adjusting the tensioning system, you can maintain the correct tension on the conveyor belt and prevent the conveyor belt from slackening or slipping during operation.

Support Structures: Support structures are used to support and stabilize conveyor belt systems. It usually consists of components such as steel frames, support columns and support rollers. The design and arrangement of the support structure ensures that the conveyor belt remains smooth and level during operation to efficiently transport items and materials.

Braking system: The braking system is used to control the stopping and starting of the conveyor belt, as well as to adjust the speed of the conveyor belt when necessary. It usually includes components such as brakes, clutches, and controls. Proper operation and adjustment of the braking system is critical to ensuring safe operation and precise control of conveyor belts.

Detection and monitoring system: The detection and monitoring system is used to monitor the status and performance of the conveyor belt system and provide necessary feedback and control. It can include devices such as sensors, encoders, monitoring instruments and controllers. Detection and monitoring systems can be used to detect parameters such as conveyor belt speed, position, tension, and offset, as well as monitor conveyor belt system failures and abnormalities.

Safety System: Safety system is an integral part of the conveyor system and is used to protect the safety of workers and equipment. It includes emergency stop devices, protective covers, safety switches and warning devices, etc. Safety systems are designed and implemented to prevent accidents and reduce the potential risk of injury.

These key components in a conveyor belt system work together to ensure efficient transfer and handling of materials during production and logistics processes. With proper design, operation, and maintenance, conveyor belt systems can improve production efficiency, reduce labor costs, and ensure safe and reliable material transportation.