Wood chips screw conveyor machine

Wednesday November-20 2024 18:02:40

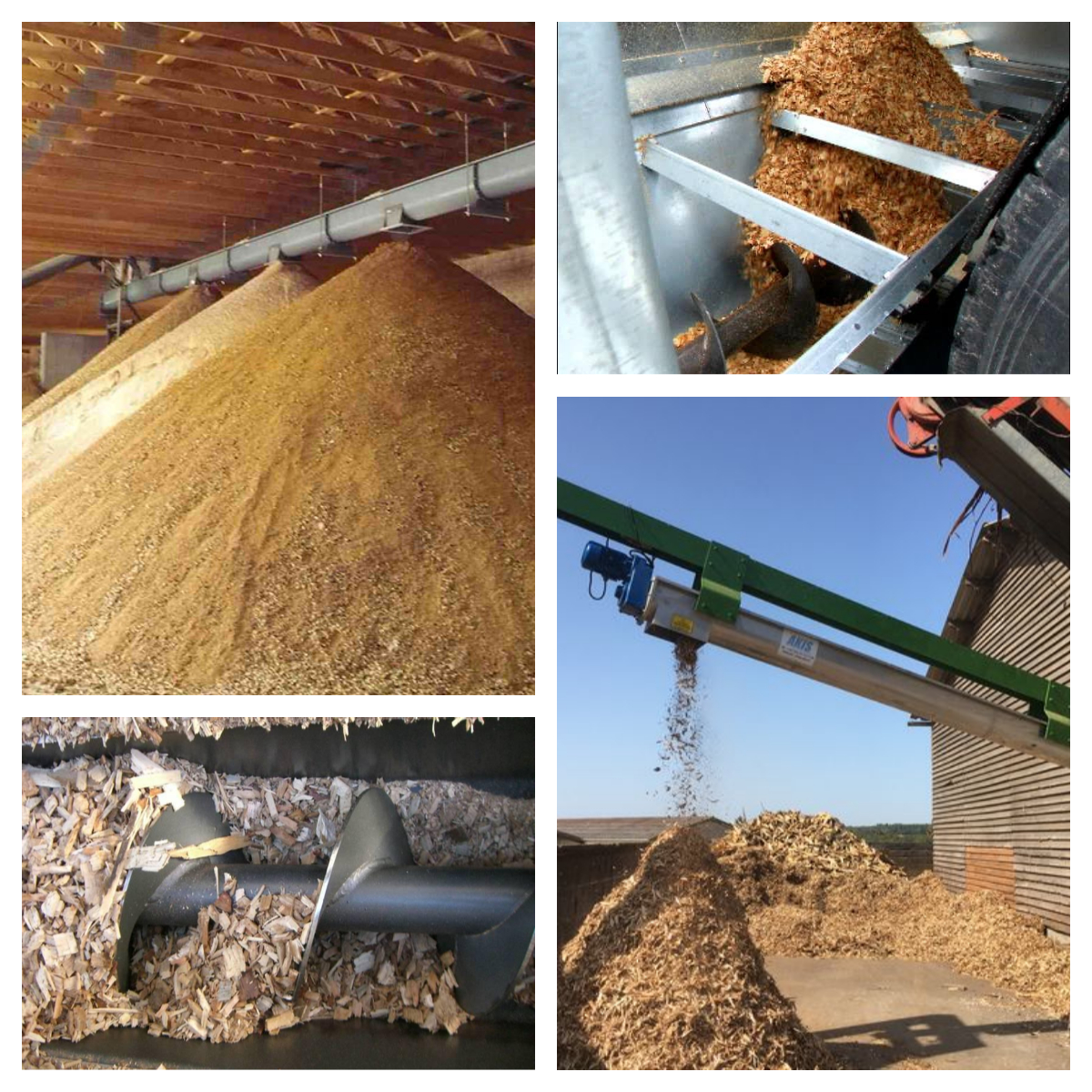

Wood chips screw conveyor machine is commonly used in industries such as woodworking, biomass processing, and paper manufacturing where the efficient and continuous transfer of wood chips is required for various processing or storage purposes.

Uses of wood chips screw conveyor machine

Screw conveyor machine can convey wood chips of various sizes, and the specific size range usually depends on the design and configuration of the conveyor. Generally speaking, screw conveyors are suitable for conveying wood chips of the following particle sizes:

Coarse-grained wood chips: The particle size can reach 20-50 mm, which is suitable for larger pieces of wood chips, such as raw materials generated during wood processing.

Medium-grained wood chips: The particle size is between 5-20 mm, which is common in the products after wood cutting and wood chipping.

Fine-grained wood chips: The particle size is less than 5 mm, which is suitable for conveying powdered or finely divided wood chips, such as sawdust or fine chips.

Application of wood chips screw conveyor machine

Wood chip screw conveyors find applications in various industries, including:

Wood Processing: Transporting wood chips from sawmills, chippers, and other processing equipment to storage silos, dryers, or biomass boilers.

Pulp and Paper Mills: Conveying wood chips to pulping and papermaking processes.

Biomass Power Plants: Transporting wood chips to biomass boilers for energy generation.

Advantages of wood chips screw conveyor machine

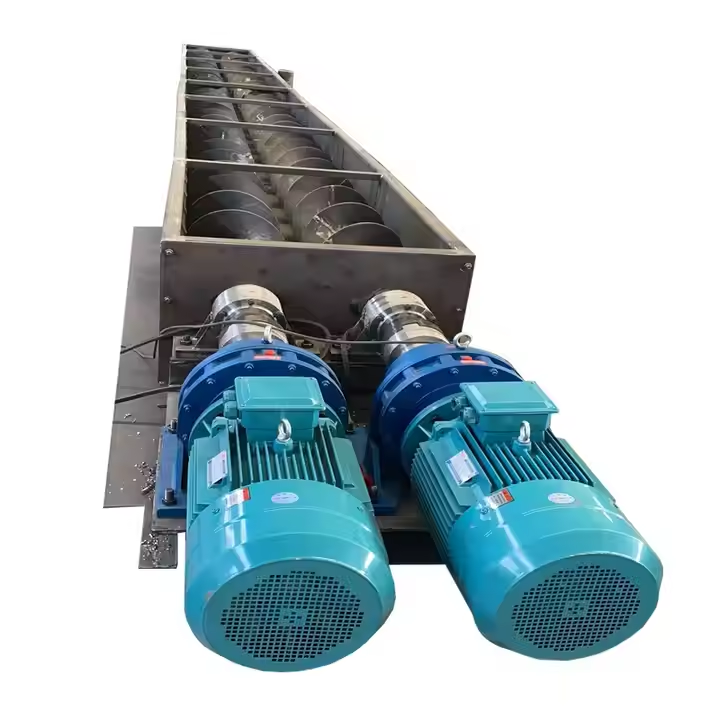

Efficient material handling: Screw conveyors are highly efficient at transporting wood chips, ensuring a smooth and continuous flow.

Reduced labor costs: Automated conveying systems minimize the need for labor, saving time and reducing labor costs.

Improved safety: By automating the material handling process, screw conveyors reduce the risk of accidents and injuries associated with manual handling.

Versatility: Screw conveyors can be customized to handle a variety of materials, including wood chips of various sizes and moisture contents.

Durability: Screw conveyors are made of high-quality materials to withstand the harsh conditions of the wood processing environment.

Sealed design: They are usually designed with a cover to prevent dust emissions and maintain a clean working environment.

Factors to consider when selecting a wood chips screw conveyor machine

Capacity: The required capacity of the conveyor should match the volume of wood chips to be transported.

Material Properties: The size, shape, and moisture content of the wood chips will influence the design of the conveyor.

Conveyor Length and Inclination: The length and inclination of the conveyor will determine the power requirements and the need for additional support structures.

Drive Mechanism: The type of drive mechanism (e.g., gear motor, hydraulic motor) should be selected based on the specific application and power requirements.

Material of Construction: The conveyor should be constructed from materials that are resistant to abrasion, corrosion, and moisture.

Wood chips screw conveyor machines are essential for efficient material handling in various industries. Their robust design and versatility make them ideal for transporting wood chips in processing and energy production applications.