Z-type bucket elevator for automatic batching materials

Friday March-14 2025 15:12:40

Z-type bucket elevator for automated batching materials is a vertical conveying equipment widely used in automated production lines, especially suitable for scenarios that require multi-point feeding and multi-point unloading. Its unique Z-type structural design enables it to achieve material lifting and transportation in a limited space, while seamlessly integrating with the automated batching system to achieve accurate and efficient material transportation and batching.

How does the Z-type bucket elevator for automated batching work?

1. A series of buckets mounted on chains or belts are used to lift materials vertically and convey them horizontally.

2. The material enters the bucket from the feed port, and as the chain or belt runs, the bucket is lifted to the required height.

3. When it reaches the unloading position, the bucket flips over and unloads the material into the target container or equipment.

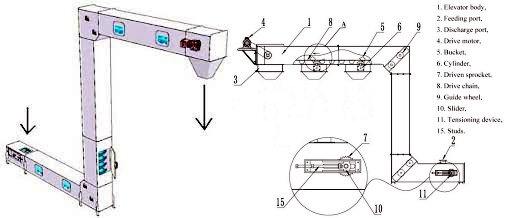

Structure of the Z-type bucket elevator for automated batching materials

Z-type bucket elevator for automated batching materials is known for its unique "Z"-shaped conveying path (horizontal-vertical-horizontal), which is suitable for scenes that require multi-point feeding or unloading. Its main components include:

Bucket: suspended on a chain or belt for loading materials.

Drive system: The chain or belt is driven by a motor to circulate.

Screening and separation device: Some models may have integrated cyclone or vibrating screen functions.

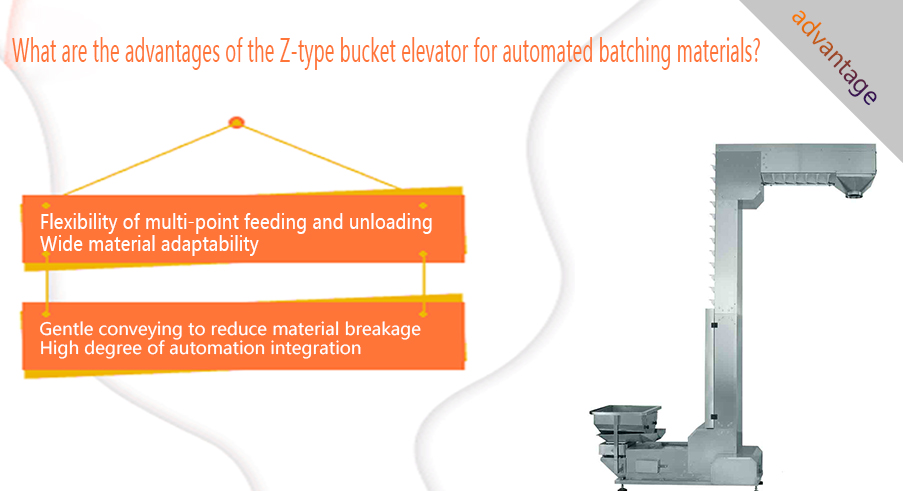

What are the advantages of the Z-type bucket elevator for automated batching materials?

1. Flexibility of multi-point feeding and unloading:

Z-type structure allows multiple feeding ports and unloading ports to be set in the horizontal section, which enables it to adapt to the complex needs of the automated batching system that requires multiple materials to be fed and unloaded at different positions.

2. Wide material adaptability:

It is suitable for conveying various bulk materials, including granular, powdery, blocky, etc., and has a low material breakage rate. This allows the Z-type bucket elevator for automated batching materials to be applied to a variety of different industries and production scenarios.

3. Gentle conveying to reduce material breakage

Z-type bucket elevator for automated batching materials adopts low-speed conveying and flexible buckets to avoid the crushing of granular materials, which is particularly suitable for food, grain, chemical, pharmaceutical and other industries.

4. High degree of automation integration:

Z-type bucket elevator for automated batching materials can be integrated with the automated control system to realize the automated control of material conveying and reduce manual intervention, which helps to realize the intelligent management of the production process.

Technical parameters of Z-type bucket elevator for automatic batching materials

|

Parameter name |

Parameter range |

Parameter name |

Parameter range |

|

Lifting height |

5m-30m |

Conveying capacity |

10m³/h-100m³/h |

|

Bucket capacity |

0.5L-10L |

Operating speed |

0.5m/s-1.5m/s |

|

Motor power |

1.5kW-15kW |

Chain/belt material |

High-strength steel chain, rubber belt |

|

Material type |

Powder, granular, small block |

Feed port size |

200mm×200mm-500mm×500mm |

|

Discharge port size |

200mm×200mm-500mm×500mm |

Equipment material |

Carbon steel, stainless steel |

|

Control system |

PLC automatic control |

Noise level |

≤75dB |

|

Equipment weight |

500kg-3000kg |

Protection level |

IP54-IP65 |

|

Working temperature |

-20℃-80℃ |

Power supply voltage |

380V/50Hz (or customized according to customer needs) |

|

Equipment size |

Customized according to customer needs |

|

|

Application of Z-type bucket elevator for automatic batching materials

1. Food industry: Z-type bucket elevator for automatic batching materials can realize multi-point feeding, lift different raw materials (such as flour, sugar, nuts, chocolate beans, etc.) from their respective storage bins to the top of the mixer to realize automatic batching.

2. Chemical industry: Z-type bucket elevator for automatic batching materials can be used to lift powder from the storage bin to the top of the reactor or mixer to realize automatic conveying and batching. Various chemical powders need to be conveyed and batched.

3. Pharmaceutical industry: Z-type bucket elevator for automatic batching materials can realize multi-point feeding, lift different raw materials to the top of the mixer or granulator to realize automatic batching, and pharmaceutical intermediates need to be conveyed.

4. Battery industry: Z-type bucket elevator for automatic batching materials can mix positive electrode materials, negative electrode materials, electrolytes, etc. in precise proportions, realize multi-point feeding, lift different materials to the top of the mixer, and realize automatic batching.

Z-type bucket elevator for automated batching materials is an important conveying equipment in automated production lines. Its high efficiency and reliable performance provide strong support for automated production in various industries.