Z-type bucket elevator for pet food

Wednesday March-19 2025 14:43:50

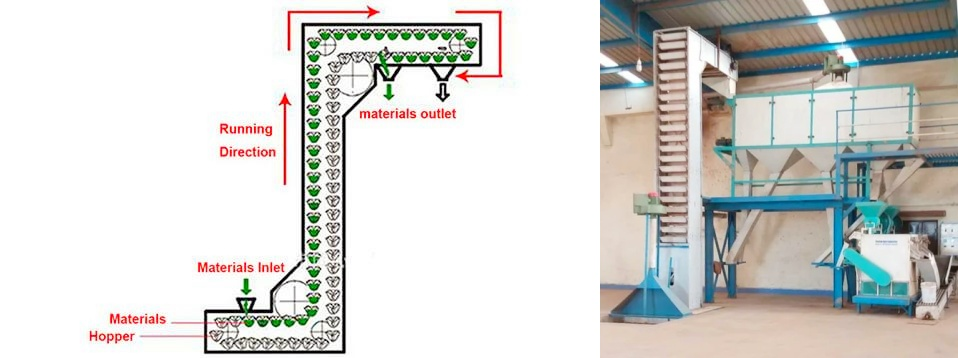

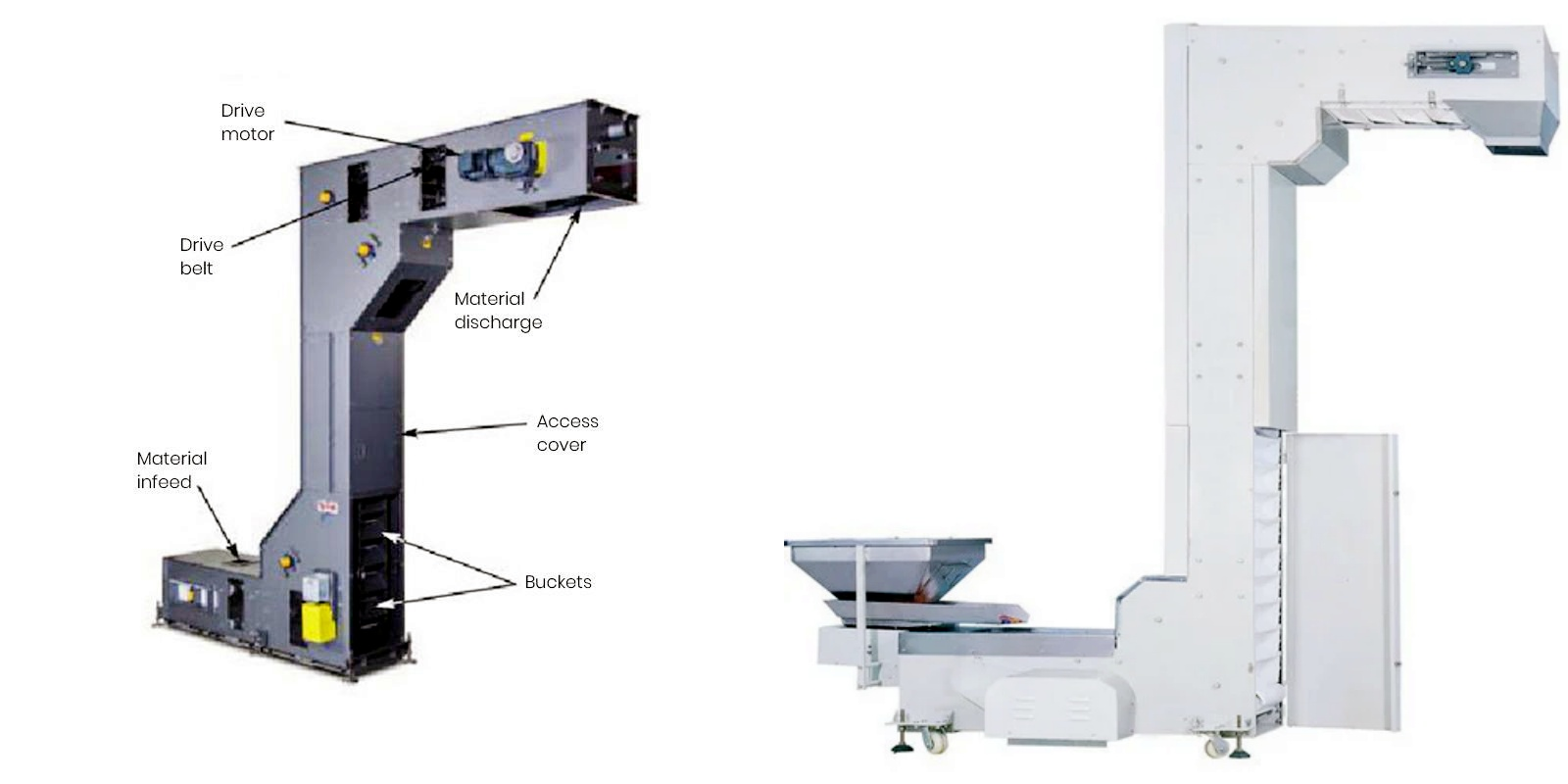

Z-type bucket elevator for pet food is a device specially used for vertical or near-vertical conveying of pet food materials. It is characterized by a Z-shaped path design, combining the functions of vertical lifting and horizontal conveying, and can gently transport materials in the horizontal-vertical-horizontal direction to avoid damage or scattering of materials during conveying. It is suitable for occasions where multi-point feeding and discharging are required, and is particularly suitable for the conveying of materials in the pet food industry.

How does the Z-type bucket elevator for pet food work?

Z-type bucket elevator for pet food drives the hopper to circulate through a chain or belt to achieve continuous or intermittent conveying of pet food. After the pet food enters the hopper from the feed port, it is lifted to the discharge port as the equipment operates, and finally the conveying is completed.

Applicable materials for pet food Z-type bucket elevator

Granular and powdered pet food: dog food, cat food, pet milk powder, nutritional powder, etc., suitable for conveying from mixer to packaging machine.

Flake pet food: pet snack flakes, biscuits, etc., suitable for conveying from molding machine to packaging machine.

Wet pet food: pet canned food, wet food, etc., suitable for conveying from filling machine to packaging machine.

Freeze-dried pet food: freeze-dried meat, vegetables, etc., suitable for conveying from freeze dryer to packaging machine.

Mixed materials: mixed materials of various pet food raw materials, suitable for conveying from mixer to molding machine.

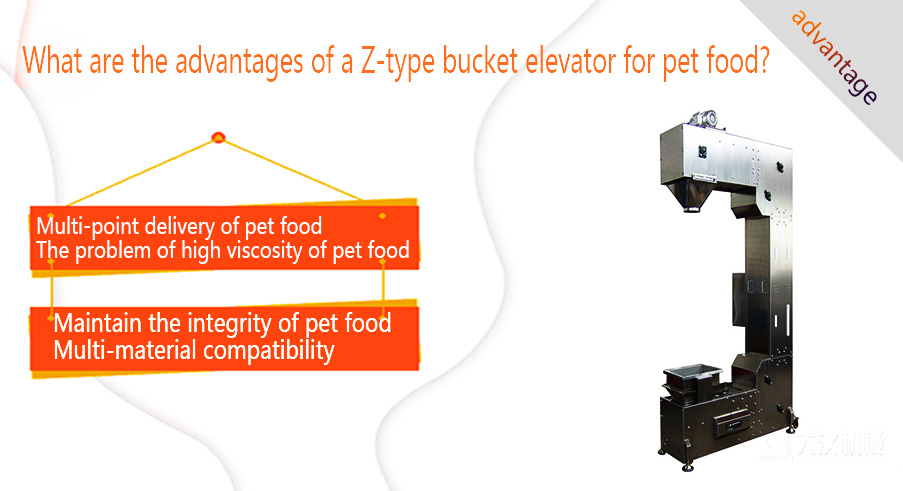

What are the advantages of a Z-type bucket elevator for pet food?

1. Multi-point delivery of pet food: A pet food production line may need to deliver materials to multiple different processing links or packaging lines. Z-type bucket elevator for pet food can be set up with multiple unloading points to achieve multi-point delivery.

2. The problem of high viscosity of pet food: Some pet foods (such as wet food and oily materials) are highly viscous and easily adhere to the surface of the equipment, causing blockage or contamination. The surface of the hopper can be coated with an anti-stick coating to reduce material adhesion.

3. Maintain the integrity of pet food: The Z-type path design combines horizontal-vertical-horizontal sections to prevent pet food from falling directly from a height. The gentle dumping method is adopted, and the material is unloaded in a low-speed and controlled manner to prevent breakage.

4. Multi-material compatibility: The same production line needs to switch different materials (such as pellets, powders, freeze-dried blocks). The modular design of Z-type bucket elevator for pet food supports the replacement of hoppers of different specifications within 5 minutes.

Technical specifications of Z-type bucket elevator for pet food

|

Parameters |

Specifications |

Parameters |

Specifications |

|

Equipment type |

Z-type bucket elevator |

Conveying capacity |

1-20 m³/h |

|

Lifting height |

2-15m |

Horizontal section length |

1-10m |

|

Bucket capacity |

1-10L |

Bucket material |

Food grade stainless steel (304/316) or PP plastic |

|

Bucket spacing |

200-600mm |

Chain/belt material |

Stainless steel chain or food grade rubber belt |

|

Operating speed |

0.5-15 m/min |

Power |

0.75-5.5 kW |

|

Voltage |

220V/380V, 50/60Hz |

Machine weight |

300-1500 kg |

|

Dimensions |

Length × Width × Height: Customized |

Operating temperature range |

-20℃ to 120℃ |

|

Noise level |

≤75dB |

Protection level |

IP54 or higher |

|

Control mode |

PLC automatic control/manual operation |

Additional functions |

Non-stick coating, vibration device, dust removal system, CIP cleaning system |

|

Applicable materials |

Pellets, blocks, powders (such as dog food, freeze-dried snacks, wet food raw materials) |

Safety design |

Emergency stop button, anti-skid chain, overload protection |

Application of Z-type bucket elevator for pet food

1. Pet food production line: Z-type bucket elevator for pet food is used to transport pet food raw materials from the bottom to the mixer, packaging machine and other process equipment above, to achieve continuous transportation of automated production lines.

2. Pet food processing plant: Z-type bucket elevator for pet food is suitable for material transportation within pet food processing plants, such as transporting dried pet food particles to the packaging area or storage warehouse.

3. Pet food packaging line: Z-type bucket elevator for pet food is used to transport the packaged pet food bags from the bottom to the packaging machine or weighing machine above, improving the production efficiency of the packaging line.

4. Pet food storage: Z-type bucket elevator for pet food can be used for material transportation inside the pet food warehouse, transporting pet food particles from the ground to storage areas at different levels.

5. Pet food quality inspection area: Z-type bucket elevator for pet food is used to transport pet food samples or materials to be tested from the bottom to the quality inspection equipment above, which is convenient for quality inspection and sorting.

Precautions for Z-type bucket elevator for pet food

Cleanliness: The bucket and conveying path of Z-type bucket elevator for pet food need to be cleaned regularly to avoid contamination by grease or residue in pet food.

Speed control: Adjust the lifting speed according to the material characteristics (such as brittleness or viscosity) to avoid too fast material spillage or too slow to affect efficiency.

Customization: The angle and bucket capacity of Z-type bucket elevator for pet food can be adjusted according to the height and layout of the pet food production line.

Z-type bucket elevators for pet food are widely used in the pet food industry, and are particularly suitable for conveying granular, powdered, flake and other materials. Its Z-shaped layout and multi-point feeding and discharging design can flexibly adapt to the needs of the production line while meeting the hygiene and safety standards of the food industry.