Z-type bucket elevator for weighing and packaging materials

Thursday March-20 2025 12:08:02

Z-type bucket elevator for weighing and packaging materials is suitable for vertical conveying of powdered, granular and small block materials, and is widely used in food, chemical, pharmaceutical, agricultural, feed, plastic, new energy and other industries. It is particularly suitable for use with weighing and packaging systems, and can achieve material lifting from low to high places, and is widely used in scenes that require gentle handling of materials, such as the conveying of powdered, granular materials or fragile items.

Video of Z-type bucket elevator for weighing and packaging materials

Material form Typical materials Applicable industries

|

Material form |

Typical materials |

Applicable industries |

|

Particles |

Rice, nuts, plastic particles, pills, catalyst particles |

Food, chemicals, medicine, plastics, new energy |

|

Powders |

Flour, milk powder, dye powder, silica powder, feed powder |

Food, chemicals, feed, medicine |

|

Flakes/blocks |

Tablets, capsules, potato chips, frozen food, metal sheets |

Food, medicine, hardware |

How does the Z-type bucket elevator for weighed and packaged materials work?

The weighed and packaged materials enter the hopper from the feed port, and the drive device drives the chain to circulate through the sprocket, so that the hopper is lifted to the top along with the conveyor chain, and then turns downward after passing the top wheel, and the weighed and packaged materials are poured into the receiving trough, completing the conveying from low to high.

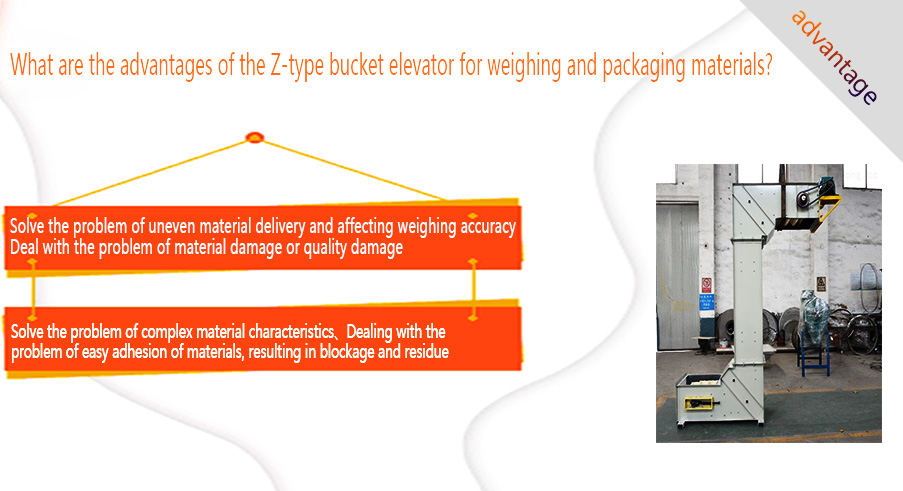

What are the advantages of the Z-type bucket elevator for weighing and packaging materials?

1. Solve the problem of uneven material delivery and affecting weighing accuracy

Lightweight particles and high-flow powders are unevenly delivered, affecting weighing accuracy. The variable frequency speed-regulating motor of the Z-type bucket elevator for weighing and packaging materials can adjust the conveying speed according to the needs of the packaging machine and accurately match the weighing rhythm.

2. Deal with the problem of material damage or quality damage

Fragile materials or high-value materials may be damaged due to extrusion and collision during transportation. The Z-type bucket elevator for weighing and packaging materials has an adjustable running speed (such as 0.5-2 m/s). For fragile materials, a low-speed mode is used to reduce the impact force.

3. Solve the problem of complex material characteristics

The material may be powdery, granular, blocky or sticky, with different characteristics, which is easy to cause blockage, adhesion or dust. Select the appropriate hopper material and shape according to the material characteristics to avoid material adhesion or blockage.

4. Dealing with the problem of easy adhesion of materials, resulting in blockage and residue

High-humidity food powder, chemical powder, and pharmaceutical powder materials adhere to the inside of the elevator, resulting in poor transportation, blockage or mixing. The Z-type bucket elevator for weighing and packaging materials uses stainless steel to effectively reduce the adhesion of materials.

Technical parameters of Z-type bucket elevator for weighing and packaging materials

|

parameter name |

basic parameters |

description |

|

lifting capacity |

1-20m³/h |

depends on material density and bucket capacity |

|

lifting height |

2-20m (customizable) |

customized height according to production needs |

|

bucket width |

150mm/200mm/300mm/400mm/500mm |

suitable for different conveying volumes |

|

bucket capacity |

0.5L/1L/2L/4L/6L |

selected according to material characteristics |

|

Lifting speed |

0.5-3m/s (adjustable) |

Frequency conversion speed control |

|

Frame material |

Carbon steel/Stainless steel 304/Stainless steel 316L |

Food and pharmaceutical industries recommend stainless steel |

|

Hopper material |

ABS/PP/Stainless steel 304 |

Suitable for different materials, anti-sticking and anti-corrosion |

|

Motor power |

0.75kW-5.5kW |

Matched according to conveying volume and height |

|

Power supply |

220V/380V/415V/50-60Hz |

Customizable different voltage specifications |

|

Drive mode |

Motor Reducer |

stable and reliable, low maintenance cost |

|

control system |

PLC frequency conversion speed regulation |

precise control of conveying speed, matching weighing and packaging requirements |

|

conveying angle |

90° (Z type) |

ensure stable material conveying |

|

applicable temperature |

-20°C~80°C |

customizable high temperature resistant materials for high temperature environment |

|

material adaptability |

granules/powders/flakes/tablets/capsules |

suitable for materials in various industries |

Application of Z-type bucket elevator for weighing and packaging materials

1. Food industry: puffed food packaging

Z-type bucket elevator lifts puffed food from a low vibrating screen or drying equipment to a high place. Its hopper is made of food-grade polypropylene to avoid contamination, and the soft and smooth design ensures that fragile materials such as potato chips are not crushed.

2. Nut industry: mixed weighing and packaging of multiple varieties

Z-type bucket elevator is equipped with multiple feeding ports, each of which corresponds to a feeding hopper for a type of nut. The materials are transported to the weighing and batching system at a high place through the elevator, and then mixed and discharged to the packaging machine after accurate proportioning.

3. Chemical industry: quantitative packaging of granular fertilizers

Z-type bucket elevator uses a wear-resistant stainless steel hopper. After the material enters the elevator from the silo, it is smoothly transported to a high place. The discharge port can be designed as a multi-point switch to support multiple packaging machines to operate simultaneously.

4. Pharmaceutical industry: tablet or capsule packaging

Z-type bucket elevator for weighing and packaging materials runs in a low-speed and soft mode, and the inner wall of the hopper is smooth to avoid scratches or damage to the tablets. The elevator realizes intermittent feeding in accordance with the needs of the packaging machine. The whole machine is made of 304 stainless steel and meets GMP standards.

5. Pet food industry: Cat food pellet packaging

Z-type bucket elevator uses multiple parallel tracks to lift different pellets such as chicken flavor and fish flavor separately to complete mixed or single flavor packaging. The lifting height is about 4 meters, the horizontal conveying section is 6 meters, and the hopper capacity can be customized to 2 liters per bucket.

If you need a specific model or personalized customized parameters, you can tell the customer service your material type, conveying volume, lifting height, packaging equipment and other requirements, we will recommend the appropriate configuration for you and provide a quotation.