heat resistant bucket elevator for cement clinker

Wednesday July-26 2023 12:15:17

What is heat resistant bucket elevator for cement clinker ?

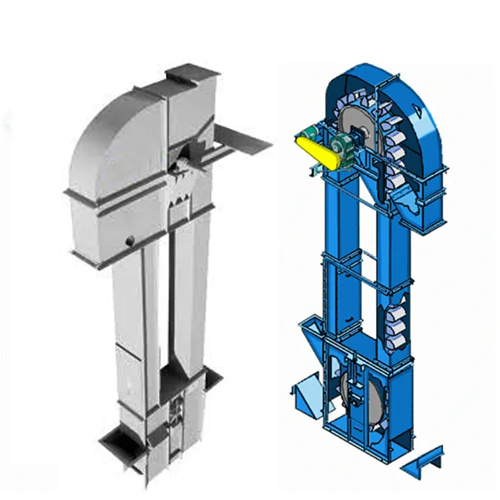

Heat resistant bucket elevator for cement clinker is a kind of equipment used to transport cement clinker (also called fired clinker or raw meal) from below to above. It consists of a bucket elevator and a heat-resistant structure. Bucket elevator is a common conveying equipment, by loading clinker in a bucket and then lifting it from below to above by chain or belt. Heat-resistant structures are often used to protect the main components of the hoist from wear and corrosion caused by high-temperature clinker. The heat resistant bucket elevator for cement clinker is usually used in the clinker conveying and loading links in the cement production line.

How does heat resistant bucket elevator for cement clinker work?

Heat resistant bucket elevator for cement clinker consists of upper and lower parts. The upper part is the feeding mechanism, and the lower part is the lifting mechanism. The lifting mechanism has a built-in high-temperature-resistant lifting bucket, and through the cooperation of the chain and the lifting wheel, the continuous vertical lifting of the material is realized.

The specific working process is as follows:

1. When the elevator starts, the raw material enters the elevator bucket from the feed port.

2. With the operation of the hoist, the hoist bucket is lifted up and unloads the material to the target position.

3. After the lifting bucket is unloaded, it will quickly return to the initial position to continue the next lifting.

What are the advantages of heat resistant bucket elevator for cement clinker?

1. Good heat resistance: Heat resistant bucket elevator for cement clinker is made of special high-temperature-resistant materials, which can work normally in high-temperature environments and maintain stable performance.

2. High lifting efficiency: The lifting mechanism adopts a continuous lifting method, which improves the material conveying efficiency and can meet the rapid lifting needs of a large number of materials.

3. Stable and reliable structure: Heat resistant bucket elevator for cement clinker adopts a solid steel structure, which can withstand large material weight and working pressure, ensuring the stability and reliability of the equipment.

4. Easy to operate: The control system of the hoist is easy to understand and easy to operate, which can realize automatic control and reduce the labor intensity of the staff.

What is the use of heat resistant bucket elevator for cement clinker?

Heat resistant bucket elevator for cement clinker is widely used in cement factories, metallurgical industry, power industry and other scenes that need to transport high-temperature materials.

1. Cement factory: In cement production, clinker needs to be transported from the kiln to the clinker warehouse for storage, and the hoist can meet the vertical transportation requirements of cement clinker.

2. Metallurgical industry: Metallurgical enterprises need to vertically lift high-temperature materials such as slag in high-temperature processes, and the hoist can efficiently and stably complete this task.

3. Electric power industry: In the coal-fired system of thermal power plants, high-temperature materials such as coal ash need to be lifted and conveyed vertically. The hoist can meet these needs and improve work efficiency.

What is the role of bucket elevator in cement clinker material?

The function of the bucket elevator in the cement clinker material is to transport the clinker from the bottom to the top. Clinker is a raw material in the cement production process, which needs to be transported to a high place for subsequent processing. The bucket elevator realizes the vertical conveying of materials through the bucket elevator chain and bucket. Through the operation of the hoist chain, the bucket lifts the clinker from the bottom to the top charging port, thereby realizing the delivery of clinker. This can improve production efficiency, speed up material handling, and save time and labor costs for manual handling.