Ash screw conveyor

In power plants and incineration facilities, ash screw conveyors are often integrated into ash handling systems to transport ash from boilers, furnaces, or incinerators to storage silos, disposal areas, or further processing equipment.

Diameter: 114-400m

Length: 2-12 meters

Capacity: 54-75 t/h

Application: Commonly used for handling fly ash, bottom ash, boiler ash, and other types of ash generated from combustion processes.

Introduction

Ash screw conveyor is a type of conveyor that uses a helical screw to move ash horizontally or at an incline. They are most commonly used in power plants to transport fly ash, a byproduct of coal combustion, from the boiler to a storage silo or truck for disposal. Ash screw conveyors can also be used in other industrial applications to transport other dry, bulk materials such as wood chips, sawdust, and grain.

These conveyors typically consist of a helical screw enclosed in a tube or trough. The screw rotates within the casing, creating a continuous flow of material along the conveyor length. The design can vary based on the specific requirements of the application, such as the type of material being handled, the distance of transportation, and the flow rate needed.

Features and Benefits

1. Flexible and adjustable: The conveying length of the ash screw conveyor can be adjusted according to the needs to meet the needs of different working conditions.

2. Stable operation: It adopts motor drive, which can realize continuous and stable material transportation and reduce vibration and noise.

3. Simple structure: Due to the simple overall structure, maintenance and cleaning are relatively convenient.

4. Strong adaptability: It is suitable for conveying various bulk materials, such as ash, coal powder, granules, etc.

5. Energy saving and environmental protection: the ash screw conveyor is driven by a transmission device, which does not require additional energy supply, and is energy-saving and environmentally friendly.

Videos

Application

Ash screw conveyors are commonly used in various industries for the handling and transportation of ash and other bulk materials. Here are some applications of ash screw conveyors:

Power plants: Ash screw conveyors are extensively used in coal-fired power plants to transport fly ash and bottom ash generated during the combustion process. These conveyors efficiently transport the ash from the boiler to storage or disposal areas, such as ash ponds or ash silos.

Waste management facilities: Screw conveyors are employed in waste-to-energy plants and incineration facilities to handle ash and other residual waste materials. They help in the efficient removal and disposal of ash generated from the incineration process.

Cement industry: Ash screw conveyors find applications in cement plants for the transportation of cement kiln dust (CKD) and other coal combustion byproducts. They assist in conveying these materials to storage or processing units for further utilization or disposal.

Pulp and paper industry: Screw conveyors are used in pulp and paper mills to transport ash generated from the burning of biomass or coal in boilers. They help in the removal of ash and its subsequent disposal or utilization.

Working Principle

The ash screw conveyor mainly transports the material from the feed port to the discharge port through the rotation of the screw blade. During the working process, the motor drives the reducer to make the spiral body start to rotate, and the material is continuously pushed forward under the action of the blades. When the material reaches the discharge port, due to the action of gravity, the material will be automatically discharged from the discharge port.

Technical parameters

| Model |

Spiral diameter (mm) |

Screw-pitch (mm) |

Speed (r/min) |

Capacity (m³/h) |

| LS-100 | 100 | 100 | 140 | 2.2 |

| LS-160 | 160 | 160 | 112 | 7 |

| LS-200 | 200 | 200 | 100 | 13 |

| LS-250 | 250 | 250 | 90 | 22 |

| LS-315 | 315 | 315 | 80 | 31 |

| LS-100 | 100 | 355 | 71 | 56 |

| LS-500 | 500 | 400 | 63 | 98 |

| LS-630 | 630 | 450 | 50 | 140 |

| LS-800 | 800 | 500 | 40 | 300 |

| LS-1000 | 1000 | 560 | 32 | 280 |

| LS-1250 | 1250 | 630 | 25 | 380 |

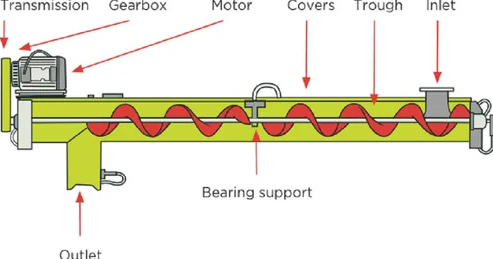

Composition Structure

The ash screw conveyor is mainly composed of a screw body, a material inlet, a material outlet, a transmission device and a supporting device. The spiral body is the main part of conveying materials, and usually consists of two or three spiral blades with different diameters. The transmission device is mainly composed of a motor, a reducer, etc., and is used to provide the rotational power of the spiral body. The supporting device is used to support and fix the conveyor.