Dry powder mortar screw conveyor

It is a conveying system specially designed to transport dry mortar materials efficiently and accurately. It is usually used on construction sites, mortar production plants and other industrial applications where dry mortar needs to be transported from one location to another.

Tilt angle: 0-60°

Length: 4-70 meters

Conveying capacity: 1.2-142m³/hour

Hopper volume: 200L

Application: Conveying different types of dry sand, cement, additives and other raw materials in mortar production lines, building construction, mortar spraying and other occasions

Introduction of dry powder mortar screw conveyor

Dry powder mortar screw conveyor is a type of conveyor specifically designed to transport dry powder mortar materials in various industrial applications. It is commonly used in construction sites, mortar production plants, and other industries that involve handling and conveying dry powder mortar.

Dry powder mortar screw conveyors are efficient and reliable in transporting dry powder mortar materials. They offer advantages such as controlled material flow, minimal product degradation, and the ability to handle various capacities and distances. These conveyors contribute to streamlining the mortar handling process and enhancing production efficiency in mortar-related industries.

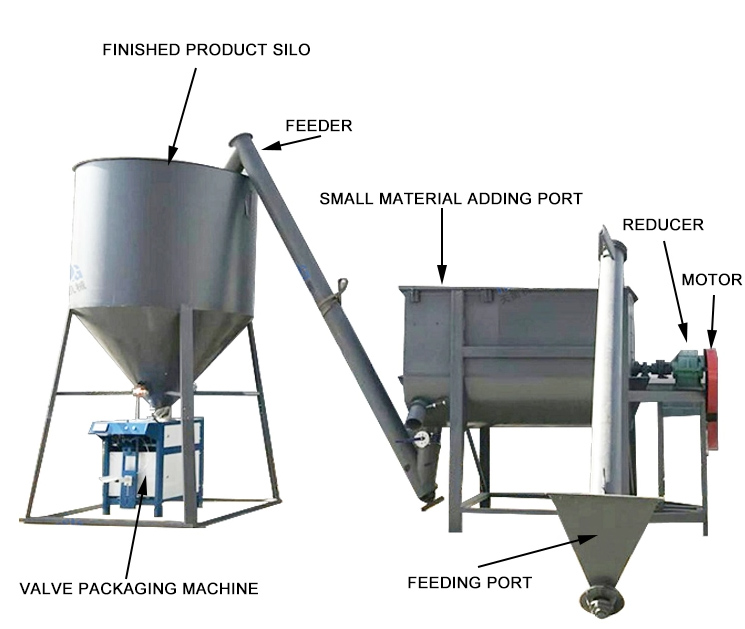

Finished product display

Working Principle of dry powder mortar screw conveyor

Here are the steps involved in the working principle of a dry powder mortar screw conveyor:

1.Material Intake: The dry powder mortar is fed into the inlet of the screw conveyor. The inlet is usually positioned at a higher elevation to allow gravity to assist in the material flow.

2.Screw Rotation: The screw or auger inside the conveyor housing rotates, driven by a motor or power source. As the screw rotates, it creates a continuous helical or spiral path along its length.

3.Material Transport: As the screw rotates, the flights or blades along its surface push the dry powder mortar forward. The helical shape of the screw creates a pushing and lifting action, effectively moving the material along the length of the conveyor.

4.Material Discharge: As the dry powder mortar advances along the screw, it reaches the outlet or discharge point of the conveyor. At this point, the material is released from the conveyor for further processing, storage, or transfer to the next stage of the production process.

Application of powder mortar screw conveyor

The powder mortar screw conveyor has various applications in industries that involve handling and transportation of dry powder mortar materials. Some of the common applications include:

1.Construction Sites: Powder mortar screw conveyors are extensively used at construction sites to transport dry powder mortar materials from one location to another. They can efficiently move materials such as cement, sand, additives, and other powdered components to the mixing area or directly to the application point.

2.Mortar Production Plants: Screw conveyors play a crucial role in mortar production plants. They are used to transport different types of dry powder mortar materials from storage silos or containers to the mixing equipment. This ensures a consistent supply of materials for the production process.

3.Plastering and Rendering: Powder mortar screw conveyors are commonly used in plastering and rendering applications. They transport dry powder mortar materials, including plastering compounds and rendering mixes, to the application area. This enables efficient and precise material placement on walls, ceilings, and other surfaces.

Video

Features and Advantages of dry powder mortar screw conveyor

1. Simple and compact structure: The dry powder mortar screw conveyor has a simple structure, consisting of a transmission device, a screw body and a feed inlet, etc. The overall volume is small, the floor space is small, and it is convenient for installation and maintenance.

2. High conveying efficiency: The screw conveyor adopts the rotating motion of the spiral body, which can quickly convey the dry powder mortar from the inlet to the outlet, which improves the production efficiency.

3. Long conveying distance: The dry powder mortar screw conveyor can set different conveying distances according to production needs, which can meet the needs of different production scenarios.

4. Adjustable conveying volume: By adjusting the speed and revolution of the screw body, the conveying volume of dry powder mortar can be flexibly adjusted to adapt to different production processes and production scales.

5. Stable and reliable operation: The dry powder mortar screw conveyor adopts high-quality transmission device and materials, which has stable operation, low noise, long service life, and can run stably for a long time.

Technical Parameters

| Model |

Spiral diameter (mm) |

Screw-pitch (mm) |

Speed (r/min) |

Capacity (m³/h) |

| LS-100 | 100 | 100 | 140 | 2.2 |

| LS-160 | 160 | 160 | 112 | 7 |

| LS-200 | 200 | 200 | 100 | 13 |

| LS-250 | 250 | 250 | 90 | 22 |

| LS-315 | 315 | 315 | 80 | 31 |

| LS-100 | 100 | 355 | 71 | 56 |

| LS-500 | 500 | 400 | 63 | 98 |

| LS-630 | 630 | 450 | 50 | 140 |

| LS-800 | 800 | 500 | 40 | 300 |

| LS-1000 | 1000 | 560 | 32 | 280 |

| LS-1250 | 1250 | 630 | 25 | 380 |

Structure of dry powder mortar screw conveyor

Here are some key structure of a dry powder mortar screw conveyor:

Screw Design: The conveyor consists of a rotating screw or auger that moves the dry powder mortar along its length. The screw is typically made of stainless steel or other durable materials and is designed to effectively convey the mortar without causing segregation or damage.

Tubular Housing: The screw is enclosed in a tubular housing, which provides containment for the mortar during transport. The housing prevents spillage and helps maintain a controlled environment for the material.

Inlet and Outlet: The conveyor has an inlet at one end where the dry powder mortar is fed into the system. At the other end, there is an outlet or discharge point where the mortar is released for further processing or storage.

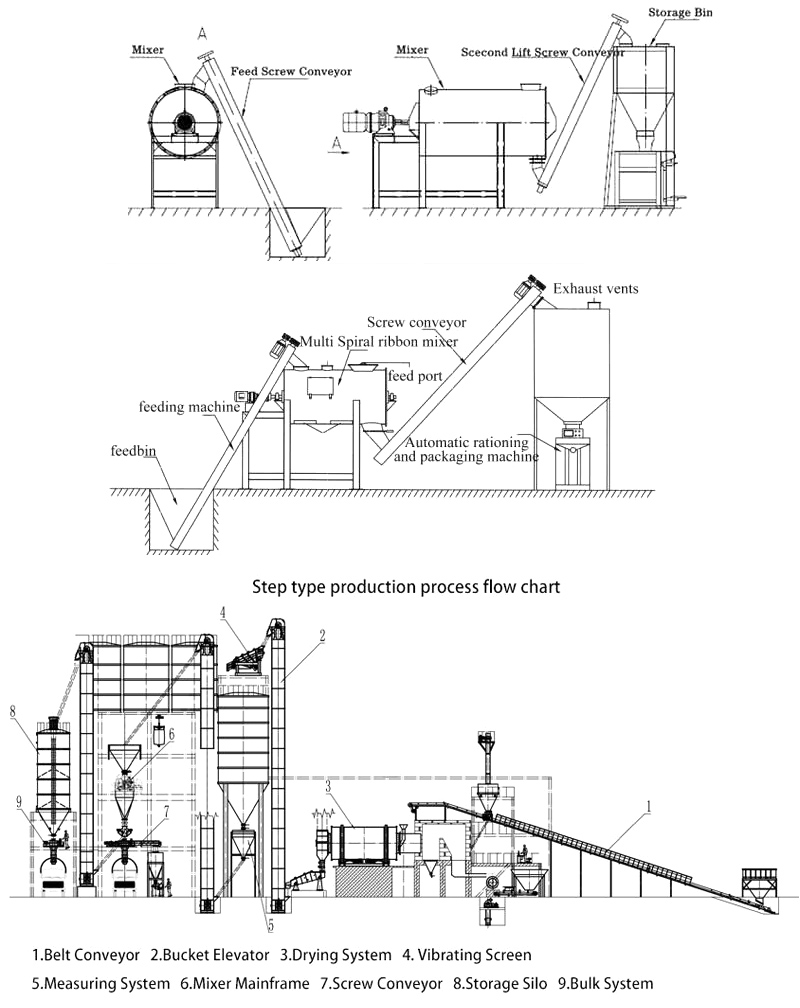

Systematic solution

Solutions by Industry

-

Building Construction Company

A building construction company is working on a large concrete structure construction project. They need to transport dry mortar materials from storage areas to concrete mixing equipment. They chose a dry mortar screw conveyor system to achieve efficient and accurate material transportation to ensure the smooth progress of the construction project.

-

Mortar Production Factory

A mortar production factory needs to transport different types of dry mortar materials from storage warehouses to mixing equipment to prepare mortar products with different formulas. They chose a customized dry mortar screw conveyor system, which can accurately convey different types of dry mortar materials according to different formula requirements, and realize the automation and efficient operation of the production process.

-

Tile Adhesive Manufacturer

A tile adhesive manufacturer needs to transport dry mortar materials to mixing equipment to prepare high-quality tile adhesive products. They chose a dry mortar screw conveyor system that can accurately control the delivery speed and amount of dry mortar to ensure the formula accuracy and production efficiency of the tile adhesive.