Fertilizer Screw Conveyor

Used to transport granular or powdered fertilizer materials from one point to another within a fertilizer production facility or during distribution.

Spiral diameter: 100-600mm

Conveying length: 2-20 meters

Conveying capacity: 30m³/h

Application: Can handle a variety of fertilizer types, including granular, powdered and granular fertilizers.

Introduction

Fertilizer screw conveyor is a type of screw conveyor specifically designed for handling and transporting fertilizer materials. In the context of handling fertilizers, a screw conveyor is typically used to transport granular or powdered fertilizer materials from one point to another within a fertilizer production facility or during the distribution process. These materials can include various types of fertilizers such as nitrogen-based, phosphorus-based, or potassium-based fertilizers, as well as compound fertilizers.

Screw conveyors are designed for continuous operation, ensuring a consistent and uninterrupted flow of fertilizer material. They are well-suited for applications that require a steady supply of fertilizer to different stages of the production process.Fertilizer screw conveyors can be integrated with other equipment, such as mixers or blenders, to facilitate the homogeneous mixing and blending of fertilizers. This allows for precise formulation and consistent quality of the final fertilizer product.

Application Scenario

Fertilizer screw conveyors are utilized for transporting various types of fertilizers, including granular fertilizers, powdered fertilizers, and blended fertilizers. They can handle different types of fertilizers, such as urea, ammonium nitrate, phosphate, potash, and organic fertilizers.

The following are common application scenarios:

Common application scenarios include but are not limited to the following fields:

1. Fertilizer production line: It can be used to transport raw fertilizers from storage warehouses or silos to production equipment such as mixers, granulators, and packaging machines to ensure continuous and stable supply.

2. Fertilizer storage and warehousing facilities: used to transport fertilizers from storage warehouses or yards to loading areas, packaging equipment or other transportation tools to achieve efficient loading and dispatching of materials.

3. Agricultural field: It can be used to transport chemical fertilizers from storage facilities to agricultural machinery such as seeders, fertilizer spreaders, and spraying equipment to achieve precise fertilization and crop growth needs.

Video

Technical Parameters

| Model |

Spiral diameter (mm) |

Screw-pitch (mm) |

Speed (r/min) |

Capacity (m³/h) |

| LS-100 | 100 | 100 | 140 | 2.2 |

| LS-160 | 160 | 160 | 112 | 7 |

| LS-200 | 200 | 200 | 100 | 13 |

| LS-250 | 250 | 250 | 90 | 22 |

| LS-315 | 315 | 315 | 80 | 31 |

| LS-100 | 100 | 355 | 71 | 56 |

| LS-500 | 500 | 400 | 63 | 98 |

| LS-630 | 630 | 450 | 50 | 140 |

| LS-800 | 800 | 500 | 40 | 300 |

| LS-1000 | 1000 | 560 | 32 | 280 |

| LS-1250 | 1250 | 630 | 25 | 380 |

Features and Benefits

1. Adapt to diversified fertilizer materials: The fertilizer screw conveyor is suitable for handling different types of fertilizer materials, including granular fertilizers, powdered fertilizers and mixed fertilizers. Whether it is urea, ammonium nitrate, phosphate, potash or organic fertilizers, screw conveyors can transport them efficiently.

2. Precise conveying control: The screw conveyor has adjustable speed and conveying volume, and can perform precise conveying control according to the needs of the fertilizer production process.

3. Adapt to the special properties of fertilizers: The fertilizer screw conveyor can handle the special properties of fertilizers, such as poor fluidity, easy caking and humidity changes. They can be designed to take into account the properties of the fertilizer to reduce problems such as clogging, clumping and dust generation.

4. Flexible configuration and layout: Whether it is horizontal transportation, vertical lifting or inclined transportation, the screw conveyor can flexibly adapt to different application scenarios.

5. Improve production efficiency: The fertilizer screw conveyor can achieve continuous and stable material transportation, improve production efficiency and reduce the need for manual handling.

6. Reduce loss and pollution: The closed design of the screw conveyor can reduce the spillage, loss and dust emission of fertilizer materials.

Working Principle

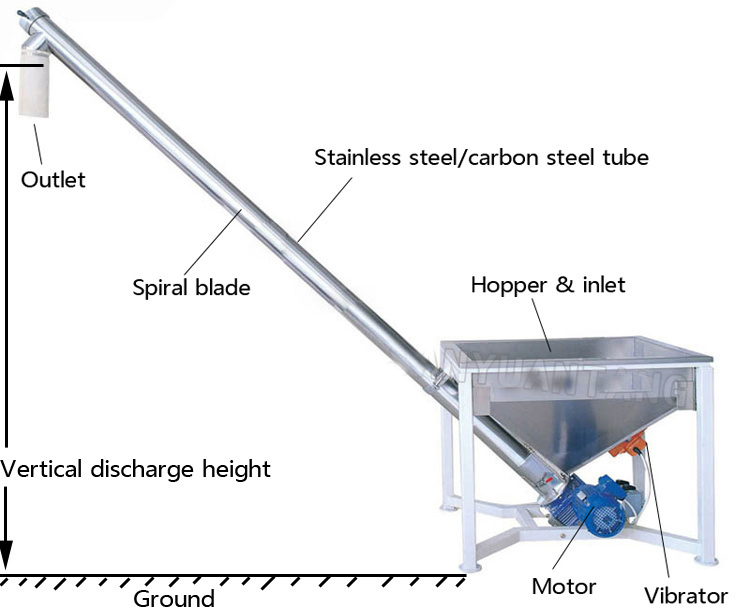

The working principle of the fertilizer screw conveyor is relatively simple. First, the material enters the machine from the feed port, and then is pushed down by the screw shaft, and conveyed along the spiral groove of the screw body during the movement. With the rotation of the screw shaft, the material gradually moves forward along the conveying direction, and is finally discharged through the discharge port.

Composition

The fertilizer screw conveyor is mainly composed of a transmission device, a screw body, an inlet, an outlet, and a supporting frame. Among them, the screw body is the core part of the equipment, which drives the screw shaft to rotate through the transmission device, so as to realize the transportation of materials.

Some key features and considerations for a fertilizer screw conveyor

1、Material Selection: Choosing materials that are resistant to corrosion and abrasion, as fertilizers can be corrosive and abrasive.

2、Screw Design: Customizing the screw design to ensure efficient and reliable transportation of fertilizer materials.

3、Capacity and Speed: Determining the capacity and rotational speed of the screw conveyor to meet the specific requirements of the fertilizer production process.

4、Safety Features: Incorporating safety features such as guards, emergency stops, and overload protection to ensure safe operation.