Flexible Grain Auger

It is a grain handling device used in the agricultural industry for the transport of grain, seeds and other agricultural products, the function of which is to suction or vacuum the grain or seed from one location to another, such as from a storage bin or drum Bins are suctioned to trucks or other transport systems.

Pipe diameter: 100mm/120mm/160mm

Length: 3-30 meters

Vertical height: 3m-4m

Conveying capacity: 4-20 tons/hour

Voltage: 220/380v or design

Conveying angle: 0-90 degrees

Suitable for conveying corn, soybean, rice, rice, wheat, sorghum, millet, quinoa and other grains.

Introduction of Flexible Grain Auger

Flexible Grain Auger is a small grain screw conveyor made of flexible pipes and bendable spirals. It can be used for loading or warehousing granular grains during busy farming seasons, and can also be used in scenarios such as grain purchases, which can greatly save time, labor input, and labor costs.

Flexible Grain Auger's regular pipeline length is 3-22m, and the length of special customization can reach 30m. It can be bent, inclined, and vertically loaded and unloaded. Only one person can complete the transportation work.

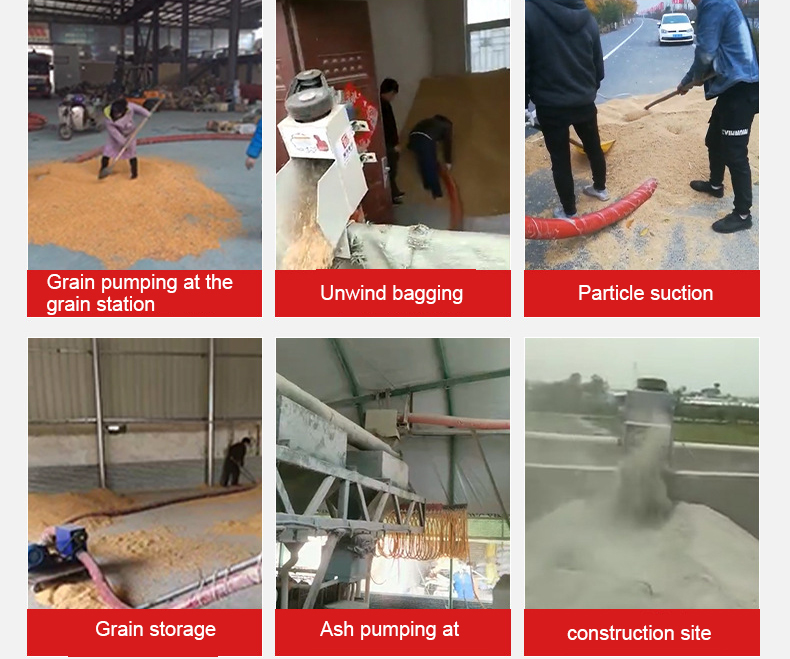

Applications

Flexible grain auger has a wide range of applications in the agricultural field, the following are some common applications:

Grain Storage and Handling: Typically used to transport grain such as wheat, corn and soybeans to storage bins and silos. They can also be used to transfer grain between different processing or handling facilities.

Seed Treatment: Can be used to transport seeds from one location to another, for example from storage bins to a seed treatment facility. They can also be used to transport treated seed to packing or distribution areas.

Livestock Feed Systems: Used in livestock feed systems to transport feed from storage bins to feeders or feeding areas. They can be customized to transport different types of feed such as pellets, powder and chopped hay.

Fertilizer handling: Used to transport fertilizers, such as granular or powdered fertilizers, from storage areas to application areas. They can also be used to deliver liquid fertilizers to irrigation systems.

Processing and Packaging: Used in processing and packaging facilities to transport agricultural products from one stage of processing to another, such as from a washing machine to a packaging machine.

Viedo

Product advantages

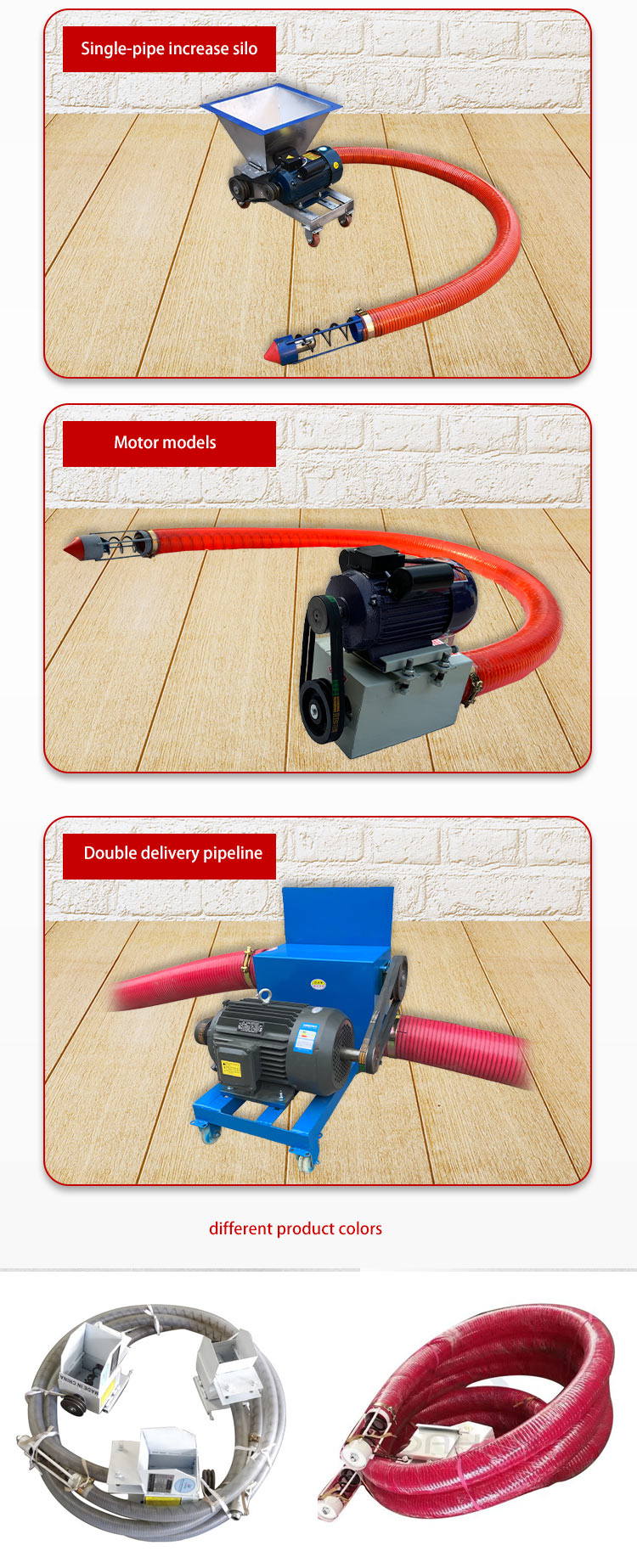

Flexibility: Designed to transport material around corners and tight spaces, the flexible tube allows the auger to bend and bend around obstacles, making it ideal for applications that require transporting material in confined spaces.

Gentle Handling: Designed to handle grain and other produce gently, which helps minimize damage to materials during transport. This is especially important with fragile or delicate materials that can be easily damaged by other types of grain handling equipment such as screw conveyors or belt conveyors.

Customization: Can be customized to meet the specific needs of different applications. They can be designed to transport grain horizontally or vertically.

Efficiency: materials can be transported at high speed. They can also be designed to run continuously, which helps increase productivity and reduce downtime.

Low Maintenance: Easy to clean and maintain, making it a popular choice for applications where hygiene and cleanliness are critical. They also require minimal maintenance, which helps reduce downtime and repair costs.

Product number

| Model No. |

Length (Meters) |

Pipe diameter |

Loading Capacity (t/h) |

Motor phase-power (kw) |

Installation | Structure | Conveying height |

| RLS100 | 4 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS120 | 4 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS-160 | 4meter | 160mm | 10—15 | Three phase-5KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5meter | |||||||

| 6meter | |||||||

| 8meter | |||||||

| (Customized) | |||||||

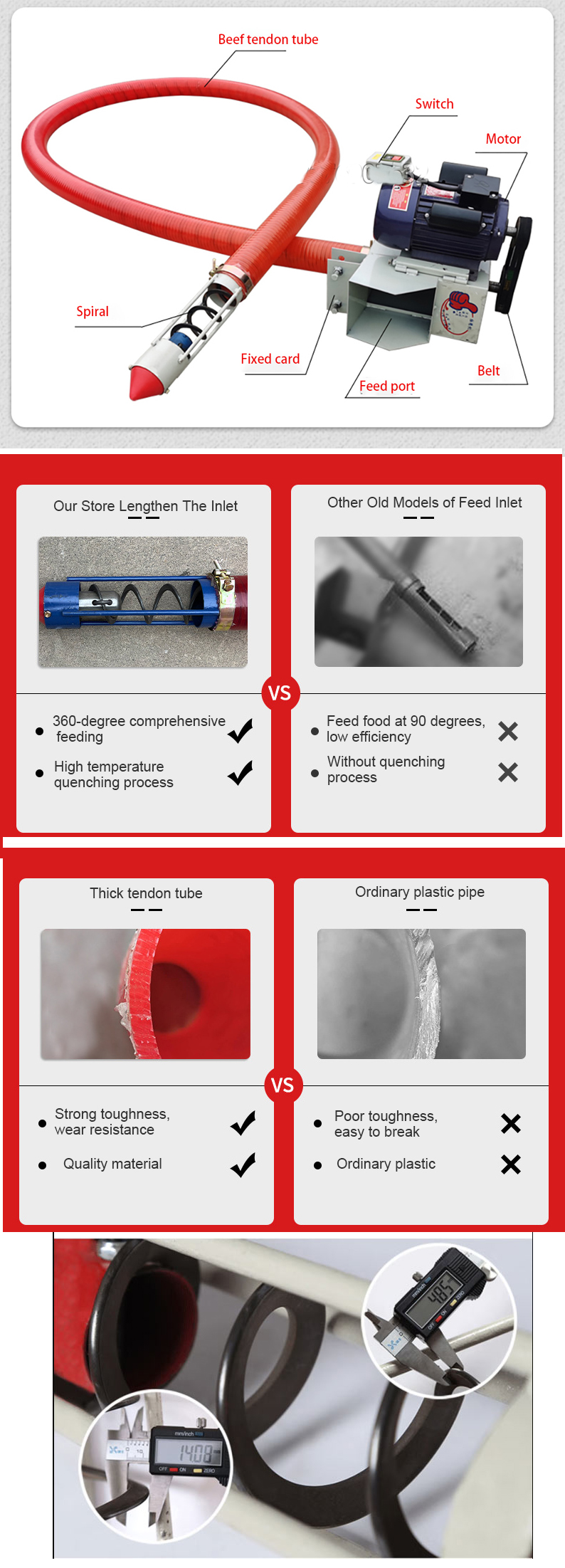

Product structure and special design

Structure and details

A flexible grain auger, also known as a flexible screw conveyor, has a simple structure that consists of the following components:

Tube: The tube is a flexible hose or tube made of steel or plastic that carries the material being transported. The tube is designed to be flexible, which allows it to bend and flex around obstacles and tight spaces.

Screw or auger: The screw or auger is a rotating helical blade that moves material along the length of the tube. The screw is typically made of steel or plastic and is designed to be gentle on the material being transported.

Motor: The motor is used to power the rotation of the screw or auger. It can be an electric motor or a tractor power take-off (PTO) system.

Inlet hopper: The inlet hopper is a funnel-shaped component that is used to direct the material into the tube. It can be customized to fit the specific needs of different applications.

Discharge valve: The discharge valve is a component that is used to control the flow of material out of the tube. It can be a simple slide gate or a more complex rotary valve.

User Feedback

-

User 1: Tour ***1

Machine model: 3m*120mm*3kw

User feedback: The product quality is very good, it is worth having!

-

User 2: Ren***4

Machine model: 4m*120mm*3kw

User Feedback: It really saves time and effort to use the machine, which saves me labor costs.

-

User 3: ****g

Machine model: 6m*100mm*3kw

User feedback: Flexible Grain Auger saves a lot of labor, and the efficiency is good, so it is worth buying. When I first received the machine, I didn't know how to use it. I consulted the customer service. The customer service was very professional and responsible. They sent me detailed instructional videos and patiently answered the questions. Good quality workmanship, economical and practical.

-

User 4: Ma***fei

Machine model: 10m*120mm*4kw

User Feedback: Loading corn with this machine is really great! It attaches directly to my car and loads corn fast!

-

User 5: u***m

Machine model: 8m*100mm*3kw

User Feedback: The machine has been received, and it is really good to use. It can pass through narrow and tortuous gaps directly. The quality of the machine is also very good, and the service attitude is good. I am very satisfied.

FAQ

Q1: How many phases does the machine use?

Answer 1: The machine has two phases and three phases, choose according to your needs

100MM*12 meters or more / 120MM*8 meters or more need to use 380V voltage

Q2: What can the machine suck?

Answer 2: The machine can absorb most of the non-fragile and small granular materials, and the materials that are wet and easy to stick and agglomerate cannot be transported

Q3: How many meters can the machine be made?

Answer 3: The length of the machine can be 30 meters, the motor is in the middle, the inlet pipe is 15 meters, the outlet pipe is 15 meters, and the voltage of 380V must be used

Q4: How many meters can it be raised?

Answer 4: 220V can generally be raised by 3 meters, and 380V can generally be raised by 4 to 5 meters (the specific transmission situation is subject to the actual situation)

Q5: How much is the output of the machine?

Answer 5: 6-8 tons per hour for 100MM, 8-10 tons per hour for 120MM, the longer the pipe length, the lower the output (this data is based on grain transportation)