Flour Screw Conveyor

Widely used in the food industry, including in bakeries, milling plants, and other flour processing facilities. They provide a cost-effective and efficient method for bulk handling of flour, enabling smooth and controlled transportation throughout the production process.

Tilt angle: 0-60°

Length: 4-20 meters

Conveying capacity: 1.2-142m³/hour

Hopper volume: 200L

Applications: Commonly used in flour mills, bakeries, food processing plants and other facilities where flour needs to be transported in bulk.

Introduction

Flour screw conveyor is a commonly used powder conveying equipment, which is widely used in food, chemical, metallurgical and other industries. The flour screw conveyor has high working efficiency, simple structure and convenient operation, and is widely used in various industries. However, it is also necessary to pay attention to the influence of factors such as the humidity and particle size of the flour during use, so as to ensure normal operation and conveying effect.

Flour screw conveyor is a type of mechanical conveying system used to transport flour or other powdered materials horizontally or at an inclined angle. It consists of a rotating screw inside a tube or trough, which moves the flour from one point to another within a processing or packaging system.

Uses

1. Grain processing industry: suitable for material transportation in grain processing production lines such as flour, starch, and oatmeal.

2. Chemical industry: It is suitable for the transportation of chemical raw materials, pigments, plastic particles and other materials.

3. Construction engineering: suitable for conveying construction materials such as concrete, cement and gypsum.

4. Environmental protection industry: It is suitable for the transportation and treatment of waste, sludge and other materials.

5. Powder coating industry: suitable for conveying powder coatings, adhesives and other materials.

Videos

Working Principle

The working principle of the flour screw conveyor is to push the flour from the feed port to the discharge port through the rotation of the spiral body. When the motor starts, the screw starts to rotate through the transmission of the transmission device. The rotation of the spiral body pushes the flour from the feed port into the pipeline, and with the spiral body continuously pushes forward, it finally reaches the discharge port to complete the entire conveying process.

Advantages

1. Efficient and reliable: The flour screw conveyor adopts a spiral screw structure and can transport flour stably and continuously. The spiral design makes the conveying process efficient and reliable, ensuring the flow and consistency of the flour.

2. Strong adaptability: Flour screw conveyor is suitable for various flour types and particle sizes. The diameter and pitch of the spiral screw can be adjusted as needed to accommodate different conveying capacities and flour characteristics.

3. Flexibility: The flour screw conveyor can convey at a horizontal or slightly inclined angle. This makes it suitable for various process layouts and application scenarios, such as the feeding and discharging of flour production lines, and transportation between different processes.

4. Environmental protection and hygiene: Flour screw conveyors are usually made of food-grade stainless steel or other materials that meet hygiene requirements to ensure that the flour transported meets food safety standards. Its design avoids flour contamination and cross-contamination and is easy to clean and maintain.

5. Space saving: Flour screw conveyors usually have a compact design and take up less space. They can be customized according to site requirements to suit limited space and layout constraints.

Technical Parameters

| Model |

Spiral diameter (mm) |

Screw-pitch (mm) |

Speed (r/min) |

Capacity (m³/h) |

| LS-100 | 100 | 100 | 140 | 2.2 |

| LS-160 | 160 | 160 | 112 | 7 |

| LS-200 | 200 | 200 | 100 | 13 |

| LS-250 | 250 | 250 | 90 | 22 |

| LS-315 | 315 | 315 | 80 | 31 |

| LS-100 | 100 | 355 | 71 | 56 |

| LS-500 | 500 | 400 | 63 | 98 |

| LS-630 | 630 | 450 | 50 | 140 |

| LS-800 | 800 | 500 | 40 | 300 |

| LS-1000 | 1000 | 560 | 32 | 280 |

| LS-1250 | 1250 | 630 | 25 | 380 |

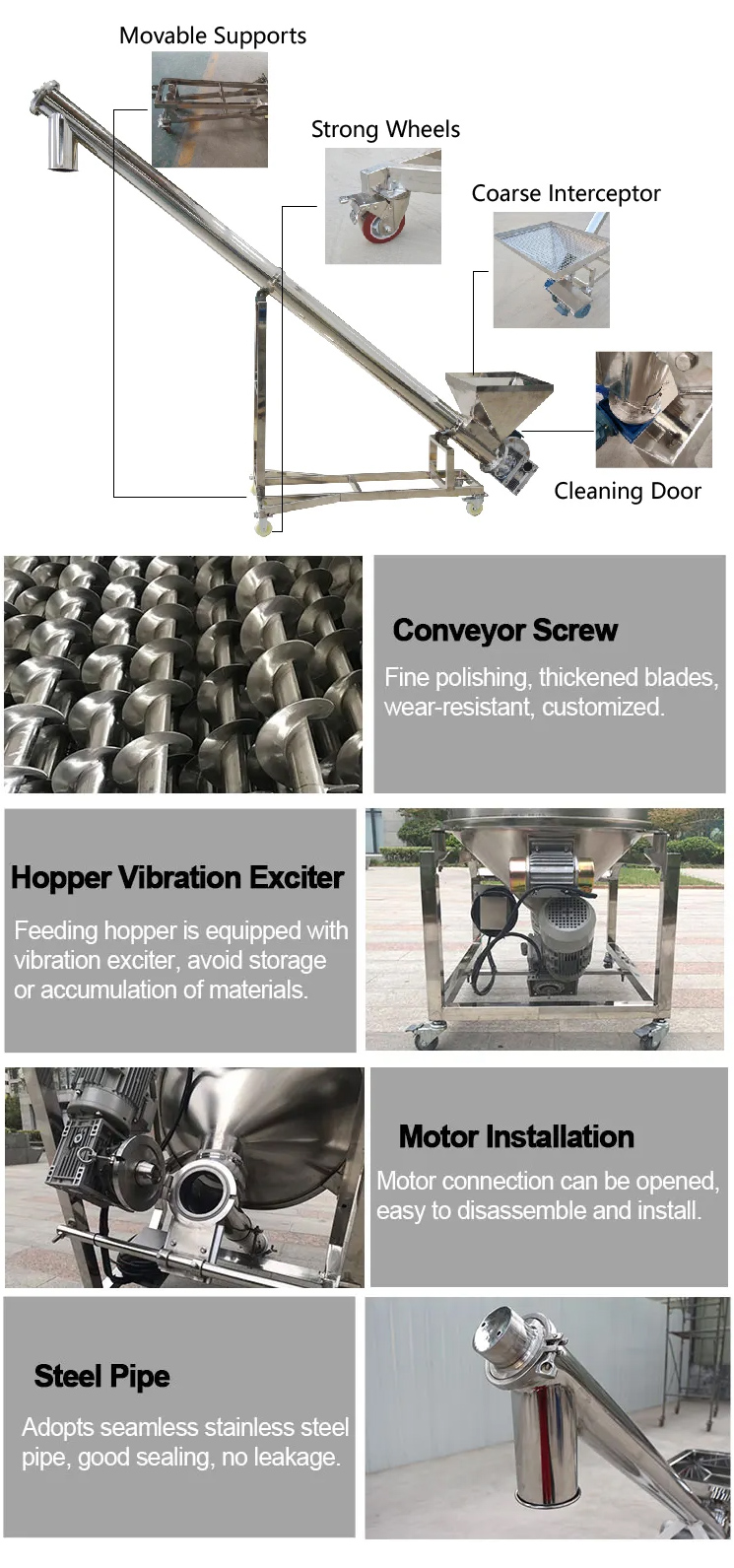

Structure

Flour screw conveyor is composed of main machine, transmission device, inlet, outlet, middle tray and other parts. The main engine is the core component of the flour screw conveyor, usually composed of a screw body, a pipe, a shaft, etc. The helix is formed by a propeller which rotates in the axial direction of the pipe. The pipeline is a channel for conveying flour, generally in a spiral shape. The shaft is the part that connects the helix and the transmission.

The transmission device is usually composed of a motor, a reducer and a coupling. The electric motor powers the transmission. The speed reducer converts the high-speed rotation of the electric motor into the low-speed rotation that pushes the screw body. The coupling connects the reducer and the main engine to transmit power.

Solutions by Industry