Grain Auger Conveyor

Grain auger conveyor is commonly used in agricultural and industrial settings for tasks such as loading and unloading grain bins, transferring grain to storage facilities or processing equipment, and filling or emptying grain trucks

Auger diameter: 114-600mm

Length: 1-20 meters

Angle: 0-90 degrees

Conveying capacity: 0.1-100m³

Applications: It can transport wheat, corn, peanuts, soybeans, rice and other grains from storage bins to processing machines, reducing the cost of manual transportation

Product Introduction of Grain Auger Conveyor

Grain auger conveyors are specialized equipment for grain transportation, typically used to load and unload grain from storage bins, transport grain to processing machines, and move grain around farms and other agricultural facilities. They are commonly used to process grains such as wheat, corn, soybeans, rice and oats, as well as other bulk materials such as fertilizers, seeds and animal feed. Their versatility, simplicity, and cost-effectiveness make them a popular choice for farmers, grain handlers, and other agricultural businesses.

Difference Between Grain Auger Conveyor and Grain Belt Conveyor

| Comparison item | Grain Auger Conveyor | Grain Belt Conveyor |

| Image |

|

|

| Delivery principle | The grain is pushed forward along the pipeline of the conveyor by the spiral rotation. | The material movement is driven by the belt, and the grain is transported from one place to another. |

| delivery volume | The transportation volume is relatively small, and it is generally suitable for small-scale grain transportation. | The transportation volume is relatively large, which is suitable for large-scale grain production and transportation. |

| Device method | Usually installed directly on the ground or between equipment, no special support system is required. | A support system is required to support and maintain the movement of the belt. |

| maintenance cost | Maintenance costs are low because they are relatively simple in construction and relatively easy to maintain and clean. | Maintenance costs are relatively high as they require more complex support systems and belt cleaning equipment. |

| Operability | Grain can be transported at any angle and direction, including horizontal, vertical and inclined. | Grain can only be transported in horizontal and inclined directions. |

Video

Advantage

1. Body material: Selected stainless steel material, non-toxic and harmless, anti-corrosion and wear-resistant, in line with the safety standards of grain transportation production.

2. Conveying distance: The conveying length of a single machine is 3-30M, and the segmented installation can reach 70M, which meets the distance requirements of different grain transportation sites.

3. Movable: It can be equipped with brakeable universal wheels or solid rubber wheels, which can move flexibly and cooperate with conveying.

4. Grain feeding in the silo: the feeding port can be equipped with a feeding silo, which saves labor when transporting bulk grain and ensures a more stable delivery flow.

5. Sealing design: fully sealed pipeline, no grain spilling or leakage during the transportation process, and no dust flying.

Application

Grain auger conveyors are mainly used in the following situations:

1. Agricultural field

In the agricultural field, Grain auger conveyors are widely used to handle and transfer grains, such as wheat, corn, soybeans, rice and barley. They are used to load and unload grain silos, move grain from one storage facility to another, and fill or empty grain trucks.

2. Seed processing

Seed processing plants use Auger conveyors to gently handle and transport a variety of seeds, including corn, sunflower seeds, cotton and vegetable seeds. They ensure efficient movement of seeds during cleaning, screening and packaging.

3. Feed mill

Grain auger conveyors are used in feed mills to transport different types of animal feed, including pellets, grains and mixed feed. They help move feed from storage silos to processing equipment such as mixers, grinders and granulators.

4. Food Processing

Grain auger conveyors are used in the food processing industry to handle and transfer a variety of granular food products, including rice, sugar, flour and pulses. They play a role in mixing, blending, packaging and transport between different processing stages.

Model parameters

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

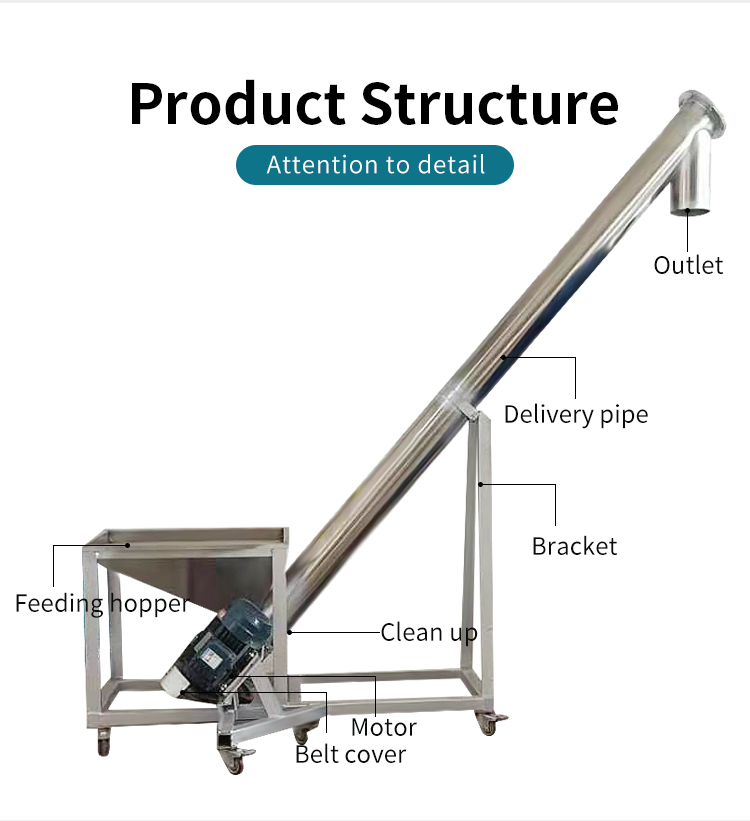

product structure

Grain Auger Conveyor is mainly composed of driving device, head section, middle section, tail section, head and tail bearings, feeding and discharging device and other parts.

1. The connection between the screw shaft and the suspension bearing, the head and the tail shaft are all connected by the embedded tongue, the installation and disassembly do not need axial movement, and the maintenance is convenient. Long mandrel, less hanging, less failure points.

2. The variable diameter structure is adopted to increase the volume of the hanging bearing to avoid the contact between the hanging bearing and the material, and the life of the hanging bearing can reach more than two years.

3. Each transmission part adopts floating connection mode, and the hanging bearing is a universal joint structure, so that the spiral body, hanging bearing and tail assembly form a whole rotating floating body, which can freely rotate and avoid with the conveying resistance within a certain range, without material jam, No clogging.

4. Both the head and tail bearing seats are outside the shell, and all bearings adopt multi-layer sealing and matching sealing technology, so the service life of the bearings is long.

Influencing Factors and Calculation of Grain Auger Conveyor's Capacity

The capacity of the Grain Auger Conveyor is used to determine the conveying amount of grain per hour. Under ideal conditions, the conveying amount is affected by the diameter of the screw conveyor, the screw speed, the density of the grain, and the conveying angle.

Grain Auger Conveyor Diameter: A larger diameter auger pushes more grain per revolution than a smaller diameter auger.

Spiral Speed: The faster the spiral speed, the more grain is moved per unit time.

Grain density: Different grains have different densities, and the density affects the grain capacity in the conveying trough.

Conveying Angle: Screw conveyors with larger conveying angles move more grain per revolution than smaller angles.

Density of grain: Different types of grain have different densities, which affect the capacity of the auger.

Angle of the auger: An auger with a steeper angle will move more grain per revolution than an auger with a smaller angle.

Also, determine the distance your grain needs to be conveyed, which is the length of the Grain Auger Conveyor.

According to the above data, substitute the following calculation formula to calculate the delivery capacity:

Capacity (bushels/hour) = (auger diameter (inches) x auger speed (rpm) x 3.14) / (angle (degrees) x 3600 x grain density (lbs/ft3))

Solutions by Industry

-

Application: Conveying corn and soybeans to processing machinery

Solution: A custom screw conveyor provided Cargill with a reliable and efficient way to move corn and soybeans from storage bins to processing machines at its plant. Screw conveyors are capable of handling the high volumes of grain required for commercial production while minimizing damage to the grain.

-

Application: Conveying wheat and soybeans to storage silos

Solution: A custom-built screw conveyor provided a reliable and efficient way to move wheat and soybeans from trucks to storage bins at its grain terminal, automating conveyance, increasing productivity, reducing operating costs and securing grain product the quality of.

-

Application: For loading and unloading grain from trucks

Solution: Can be used to load grain from storage bins or other sources into a truck with a conveyor on top of the truck and the grain is fed into a hopper at the bottom of the conveyor. As the screw rotates, it moves the grain up the conveyor and into the truck.