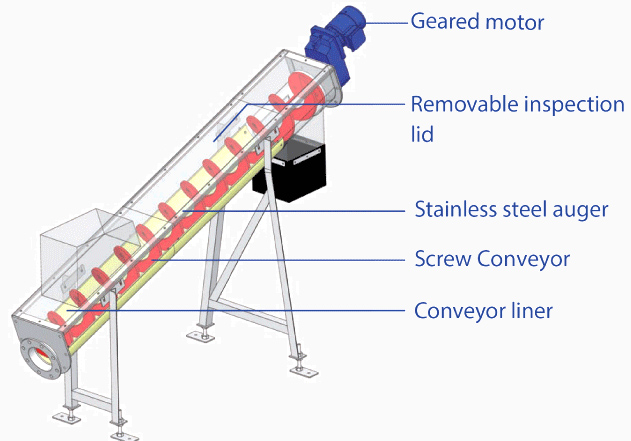

Household waste screw conveyor

Utilize auger conveyors to grind and transport food scraps to collection bins or even composting units.

Diameter: 150 - 470 mm

Inclination of installation: 0-30°

Length: 0-20 mt or 0-30 mt

Capacity: from 0.8 mc/h to 45 mc/h

Application:Suitable for handling household waste materials in waste sorting facilities, recycling plants, composting facilities and other waste management operations.

Introduction

The primary function of a household waste screw conveyor is to move household waste materials from one location to another within a waste processing facility. These conveyors use a rotating screw mechanism to propel the waste materials along a trough or tube, allowing for continuous and controlled transportation.

Household waste screw conveyors are capable of handling a variety of household waste materials, including food waste, paper, plastics, glass, metal, and other recyclable or non-recyclable items. The design of the screw conveyor can be customized to accommodate different types of waste materials.

Uses

Household waste screw conveyors have many common applications in the field of household waste processing and recycling, including but not limited to the following:

1. Household waste sorting station: In household waste sorting stations, screw conveyors can be used to transport different types of waste from collection points to corresponding sorting equipment or containers, helping to realize the automation and efficient operation of waste sorting and processing.

2. Garbage treatment facilities: In garbage treatment facilities, screw conveyors are often used to transport household waste from the inlet to garbage sorting equipment, compressors, crushers or other processing equipment to promote the smooth progress of the garbage treatment process.

3. Waste incineration power plants: In waste incineration power plants, screw conveyors can be used to transport household waste from storage areas to combustion furnaces or other combustion equipment as a pre-treatment link for waste incineration power generation.

4. Landfill: In landfills, screw conveyors can be used to transport household waste from the stacking area to the landfill area, helping to control the uniformity and compactness of the landfill.

5. Garbage recycling station: In the garbage recycling station, screw conveyors can be used to transport recyclable household waste such as paper, plastic bottles, etc. to the corresponding recycling equipment or processing lines to promote waste recycling and resource utilization.

6. Waste incineration waste gas treatment system: In the waste incineration waste gas treatment system, the screw conveyor can be used to transport the ash or waste gas treatment products after household waste incineration to the corresponding processing equipment or storage area.

Video

Advantages

Household waste screw conveyor has the following advantages:

1. High conveying efficiency: The household waste screw conveyor adopts screw transmission, which can realize continuous and efficient conveying, which greatly improves the processing efficiency of domestic waste.

2. Long conveying distance: The household waste screw conveyor can be designed into conveyors of different lengths according to needs, which can meet the needs of different sites and realize long-distance conveying.

3. Wide range of application: The household waste screw conveyor is suitable for conveying all kinds of domestic waste, whether it is solid waste, liquid waste or powdery waste, it can be conveyed by the screw conveyor.

4. Simple structure: The structure of the household waste screw conveyor is relatively simple, easy to maintain, low failure rate, and long service life.

5. Energy saving and environmental protection: the household waste screw conveyor adopts electric drive, which can save energy and reduce environmental pollution compared with traditional hydraulic or pneumatic conveyors.

Working Principle

The working principle of the household waste screw conveyor is to use the rotating motion of the spiral body to drive the waste forward. When the motor is started, the speed of the motor is reduced by the reducer, and then transmitted to the screw to make it start to rotate. After the garbage enters the feeding pipe through the feeding port, it will be pushed by the screw of the spiral body, and gradually conveyed to the discharging port along the path of the feeding pipe.

Technical parameters

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

Solutions by Industry

-

Food waste treatment system

An environmental company has developed a food waste disposal system that uses a screw conveyor to collect food waste from the kitchen sink to an outdoor treatment unit. This system can effectively reduce the amount of food waste produced and prevent environmental pollution.

Processing capacity: 100 tons/day

-

Automatic garbage classification system

A technology company has developed an automated waste sorting system that uses a screw conveyor to transport waste from different bins to a sorting device. The system can improve the efficiency of waste sorting and reduce labor costs.

Processing capacity: 50 tons/day

-

Underground garbage collection system

A construction company has developed an underground waste collection system that uses screw conveyors to collect waste from underground bins to above-ground collection stations. The system can improve urban sanitation and reduce waste transportation costs.

Processing capacity: 20 tons/day