Powder Screw Conveyor

Used to move powder horizontally, inclined or vertically. The closed conveying pipeline can prevent dust leakage and material overflow.

Pipe diameter: 113-600mm

Capacity: 500kg-30t/hour

Materials: SS304 or carbon steel

Voltage: 110V/220V/380V/415V/460V

Application: Commonly used in food processing, pharmaceutical, chemical and agricultural industries to transport powders such as flour, spices, coffee powder, mineral powder, lime powder, cement powder, etc.

Introduction

Powder screw conveyor, also called powder screw conveyor feeder, can transport powder from a hopper or storage bin to a specific point of use. The design usually consists of a rotating screw or auger within a tube or trough that moves the material along the conveyor.

Powder screw conveyors can cover a wide range from coarse powder to fine powder, including but not limited to the following types of powders: coarse powder (calcium carbonate, mineral powder, metal powder, food additives, etc.), fine powder (flour, sodium carbonate, soda ash, silicon powder), ultrafine powder (pharmaceutical powder, zinc oxide, etc.), and can also convey some powders with low viscosity, good fluidity and not easy to agglomerate.

Function

As a common material conveying equipment, the main function of the powder screw conveyor is to convey and control powdered or granular materials.

General conveying: It can realize horizontal, vertical or inclined conveying of powders, and convey materials from one place to another destination.

Quantitative conveying: By adjusting the motor speed or the gap between the spiral blades, the quantitative control of the material can be achieved to meet the precise requirements of the production process.

Mixed conveying: During the conveying process, different types of powders or granular materials can be mixed evenly to achieve the mixing function.

Cooling conveying: By setting a cooling or heating device on the outer wall of the conveyor, the temperature of the material is controlled.

Auxiliary function

Sealed conveying: Prevent material leakage and avoid pollution to the environment.

Dust removal conveying: During the conveying process, dust removal can be carried out at the same time to improve the working environment.

Stirring conveying: For some materials that are easy to agglomerate, they can be stirred during the conveying process to improve fluidity.

Types of powder screw conveyor

Powder screw conveyors can usually be divided into different types according to their structure and design:

1. Powder tube screw conveyor: It is a common design with a sealed pipe with a screw installed inside. The powder is transported to the destination through the rotation of the screw. It is suitable for situations where powder needs to be transported over a long distance. The pipeline design can ensure that the powder will not be scattered or disturbed by the outside world during the transportation process, which is suitable for stable transportation of powder.

2.Powder trough screw conveyor: It has a trough structure with a screw installed inside. The powder is transported to the destination along the trough by the push of the screw. It is suitable for situations where powder needs to be transported over a short distance. The trough design can effectively control the conveying direction and speed of the powder, and is suitable for occasions with high requirements for powder conveying accuracy.

3.Powder flexible screw conveyor: It usually has a flexible spiral structure that can adapt to different conveying angles and bends. It is suitable for special conveying needs and for situations where powder needs to be transported in a tortuous or limited space. The flexible spiral structure can adapt to various bends and corners and is suitable for complex process layouts.

Application

Food processing industry: In the food industry, powder screw conveyors are often used to convey powder raw materials such as flour, powdered sugar, and seasonings for mixing, packaging, and processing.

Chemical industry: In the chemical industry, various powder materials such as fertilizers, pigments, and plastic particles often need to be processed. Powder screw conveyors can be used in raw material transportation, mixing, and production processes.

Building materials industry: In building materials production, powder screw conveyors are often used to convey powder materials such as cement, stone powder, and gypsum for mixing, filling, and production processes.

Pharmaceutical industry: The pharmaceutical industry requires precise control and processing of various pharmaceutical raw materials. Powder screw conveyors can be used to convey raw materials such as medicinal powders and granular medicinal materials.

Metallurgical industry: In metallurgical production, powder screw conveyors are often used to convey raw materials such as metal powders and ore powders for smelting, alloy preparation, and production processes.

Powder coating production: In the coating manufacturing process, powder screw conveyors are often used to convey various pigment powders, resin powders, and other raw materials, as well as finished powder coatings.

Video

Features and Benefits

1. Reliability: Blocking and jamming are not easy to occur during material transportation, and the feeding is uniform and stable.

2. Flexibility: The powder screw conveyor can adapt to different process requirements and material characteristics. By adjusting the diameter, pitch and speed of the spiral, accurate control and regulation of materials can be achieved. Additionally, they can be customized based on site conditions to accommodate different installation and layout needs.

3. Efficiency: The powder screw conveyor can achieve continuous and uniform material transportation. The rotational motion of the screw propels material along the length of the conveyor, enabling efficient material transfer. They are often able to handle large volumes of material and maintain low energy consumption during processing.

4. Versatility: The powder screw conveyor can not only carry out horizontal transportation, but also can carry out inclined and vertical transportation. This makes them suitable for a variety of different process layouts and space constraints.

5. No dust: It has good sealing effect, prevents dust and pollution, can isolate materials with strong odor and easily raise dust, and improve the working environment.

Technical Parameters

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

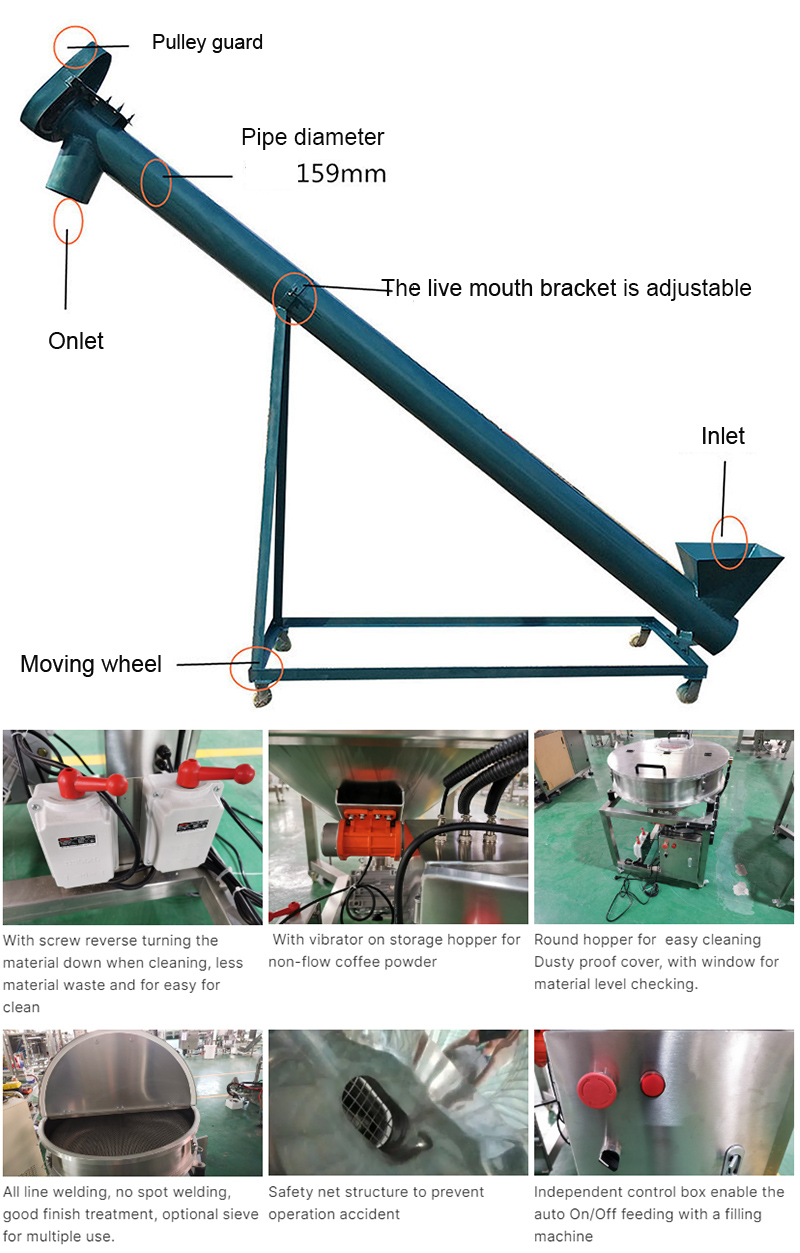

Composition Structure

The main structure of the powder screw conveyor includes the following parts:

Screw: It is usually a spiral screw made of wear-resistant material (such as stainless steel or carbon steel). The screw is fixed to the shaft and an electric motor drives the rotation of the shaft, thereby propelling the material along the length of the conveyor.

Tube/Trough: The spiral is located in the tube or trough body. They are usually made of wear-resistant, corrosion-resistant materials such as stainless steel or carbon steel. Pipes or troughs play the role of containing and protecting materials, and also provide the support needed for materials during transportation.

Inlet and Outlet: The powder screw conveyor has an inlet and an outlet. The inlet is used for inputting materials, and the outlet is used for discharging materials. The location and shape of these ports can be designed and customized based on specific application needs.

Drive System: It usually consists of a motor, reducer and coupling or belt drive. The motor provides power, and the reducer converts the high-speed rotation of the motor into a rotational speed suitable for the screw conveyor, and transmits the power to the screw through a coupling or belt.

Support Structure: Powder screw conveyors are usually installed on a support structure to provide stable support and fixation.

Conveying form of powder screw conveyor

Material conveying direction (multi-point feeding or multi-point unloading can be achieved)

The powder screw conveyor mainly realizes the material conveying through the spiral structure, and its conveying forms usually include the following:

Horizontal conveying: conveying the powder horizontally along the pipe or trough. This form is suitable for occasions where the powder needs to be conveyed in the horizontal direction, such as conveying from one place to another.

Vertical conveying: conveying the powder vertically along the pipe or trough. This form is suitable for occasions where the powder needs to be conveyed between different heights, such as conveying from the ground to the upper floor or from the upper floor to the ground.

Oblique conveying: conveying the powder obliquely along the pipe or trough. This form is suitable for occasions where the powder needs to be conveyed at an inclined angle, such as in the conveying process at different heights and with a certain slope.

Multi-point feeding and discharging conveying: Some screw conveyors have multiple feeding ports and discharging ports, which can realize the conveying form of multi-point feeding and discharging, and are suitable for complex material conveying needs.

Special design

For conveying ultrafine powders, the screw conveyor needs to consider the following factors:

Anti-blocking design: Ultrafine powders can easily block the screw of the screw conveyor during conveying, so a special design is required to prevent blockage.

Sealing requirements: Ultrafine powders often have strict environmental requirements, so the screw conveyor needs to have good sealing to prevent dust leakage.

Material selection: Select materials suitable for conveying ultrafine powders, such as stainless steel or special coatings, to prevent particles from being contaminated or blocked.

Solutions by Industry

-

Flour Manufacturer

The customer, a large flour manufacturer, uses powder screw conveyors to transport flour from storage warehouses to the production line. The screw conveyor is designed using stainless steel to ensure food hygiene and prevent contamination. They have adjustable conveying speed and capacity to meet different production needs. The stability and reliability of this conveying system ensures a continuous supply of flour and improves production efficiency.

-

Coffee Powder Packaging Company

The customer is a professional coffee powder packaging company. They use a powder screw conveyor to transport coffee grounds from storage tanks to packaging machines. The screw conveyor is designed with wear-resistant materials and equipped with seals to prevent powder leakage and contamination. They enable precise material control and regulation, ensuring accurate measurement and even distribution of coffee powder, improving packaging quality and production efficiency.

-

Cement Manufacturer

The customer is a cement manufacturer who uses powder screw conveyors to transport cement powder from storage warehouses to concrete mixing plants. The screw conveyor's structural design is sturdy and durable, and can handle high-density and larger-grained materials. They have large conveying capacity and stable operation, ensuring efficient conveying and continuous supply of cement powder, improving production efficiency and concrete quality.

Alternative Solutions

Powder screw conveyors may no longer be suitable for the following types of powders:

Highly viscous, easily agglomerated ultrafine powders: Such powders tend to adhere to the spiral blades and cause blockages.

Ultrafine powders that are prone to static electricity: Static electricity can cause dust to fly, increasing safety hazards.

Ultrafine powders that are sensitive to friction: The working principle of the screw conveyor is to convey the material forward through friction, which may cause product damage to materials that are sensitive to friction.

If the screw conveyor is not suitable for your ultrafine powder, you can consider the following alternatives:

Vacuum feeder: Uses a vacuum pump to generate negative pressure to suck the powder into the pipeline, which is suitable for conveying high-value, easily contaminated materials.

Vibration conveyor: Uses the force generated by vibration to convey the powder forward, which is suitable for conveying materials that are prone to blockage.