Pulverized Coal Screw Conveyor

Used for handling and transporting pulverized coal in power plants, industrial boilers and other applications where pulverized coal is used as a fuel source.

Diameter:114-600m

Length: 2-20 meters

Capacity: 10-30 t/h

Introduction

Pulverized coal screw conveyor is a type of conveying equipment designed specifically for handling pulverized coal. It consists of a rotating screw or auger housed within a tube, which moves the coal particles along a horizontal or inclined path.

The pulverized coal screw conveyor is commonly used in various industries, including power plants, cement plants, and industrial boilers, where pulverized coal is used as a fuel source.Pulverized coal screw conveyors can be customized to meet specific requirements, such as varying capacity, length, and inclination angles. They can be designed to fit into existing systems or integrated into new coal handling processes.

Application

The pulverized coal screw conveyor is widely used in coal pulverized transportation scenarios in coal industry, electric power industry, chemical industry and other fields. Specific application scenarios include:

1. Pulverized coal transportation links such as ash storage, coal mill, pulverized coal incineration system, etc.

2. Pulverized coal transportation in the dust removal system of the power plant.

3. Material transportation in iron and steel smelting, cement production and other processes.

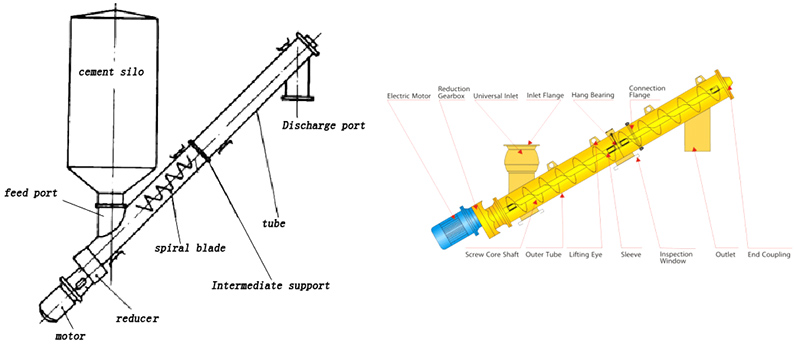

Structure

The main structure of the pulverized coal screw conveyor includes a motor, a reducer, a screw blade, an inlet, an outlet, an intermediate bearing and a base, etc.

Working Principle

The motor is connected to the reducer through a coupling to drive the reducer to work. The reducer is connected with the screw blade, driven by the motor, the screw blade starts to rotate. The material enters the conveyor from the feed port, is driven by the screw blade, moves along the spiral shape of the screw blade, and finally is discharged through the discharge port. At the same time, due to the rotation of the spiral blade, the continuous conveying of the material is formed.

Video

Features and Benefits

1.Efficient Handling: Pulverized coal screw conveyors help maintain a consistent and reliable flow of coal, which is crucial for the efficient operation of combustion systems.

2.Dust Control: Properly designed screw conveyors can help minimize dust emissions during the transport of pulverized coal.

3.Without causing segregation or degradation: The screw inside the conveyor is specially designed to effectively move and convey pulverized coal without causing segregation or degradation.

4.Customizable Design: Pulverized coal screw conveyors can be customized to meet specific requirements, such as varying capacity, length, and inclination angles. They can be designed to fit into existing systems or integrated into new coal handling processes.

Technical parameters

| LS type | GX type) | Delivery QΦ=0.33(m3/h) | Power Pd 1=10m(KW)) | Power Pd 1=30m(KW) | Revolving speed(r/min) | Delivery QΦ=0.33(m3/h) |

| 100 | 2.2 | 1.1 | 1.6 | 120 | 1.9 | |

| 160 | 7.6 | 1.5 | 2.8 | 90 | 5.7 | |

| 200 | 200 | 11 | 2.2 | 3.2 | 75 | 18 |

| 250 | 250 | 22 | 2.4 | 5.3 | 75 | 18 |

| 315 | 300 | 36.4 | 3.2 | 8.4 | 60 | 29.1 |

| 400 | 400 | 66.1 | 5.1 | 11 | 60 | 52.9 |

| 500 | 500 | 93.1 | 4.1 | 15.3 | 45 | 69.8 |

| 630 | 60 | 160 | 8.6 | 25.9 | ||

| 800 | 223 | 12 | 36 | 35 | 174 | |

| 1000 | 304 | 16 | 48 | 30 | 261 | |

| 1250 | 458 | 24.4 | 73.3 | 20 | 305 |

Considerations

Material Characteristics: Consider the specific characteristics of the pulverized coal being handled, such as particle size, moisture content, and abrasiveness, to ensure the conveyor is designed appropriately.

Capacity and Speed: Determine the required capacity and speed of the conveyor to meet the demands of the application.

Safety: Ensure that the conveyor is equipped with safety features to prevent accidents and protect personnel working around the equipment.