Screw Conveyor for Sand

It can be used for short and long distance transportation and can handle various types of sand.

Spiral diameter: 100-1250mm

Conveying length: 2-20 meters

Conveying capacity: 142m³/h

Speed: 60 rpm

Application: quartz sand, silica sand, emery, mineral sand, river sand, etc.

What is Screw Conveyor for Sand?

Screw conveyor for sand is a specific type of screw conveyor designed to handle and transport sand or other granular materials. It is commonly used in various industries such as construction, mining, agriculture, and manufacturing.

The design of the screw conveyor for sand takes into account the characteristics of sand, such as its granular nature, particle size, density, and flowability. The helical flighting of the auger is designed to create a continuous conveying surface that effectively moves the sand without causing excessive abrasion or damage.

Types of Screw Conveyor for Sand

There are several types of screw conveyors that can be used for transporting sand efficiently. Here are some common types:

1.Tubular Screw Conveyor for Sand:The screw conveyor is suitable for horizontal, inclined or vertical transportation. It can be used for long-distance transportation or transportation between different heights. It can be used to transport dry sand or wet sand. It is suitable for construction, concrete manufacturing, excavation and other fields.

2.Flexible Screw Conveyor for Sand: Flexible screw conveyors are specifically designed to handle large volumes of sand and are commonly used to transport dry sand on construction sites.

Application

Screw conveyor for sand plays an important role in many different applications. Here are some common applications:

1. Construction industry: used to transport sand to concrete mixing stations or other construction sites. They can help transport sand from storage areas to where it is needed, making construction more efficient.

2. Concrete production: It can be used to transport sand to concrete mixers or mixing stations to ensure the accuracy and uniformity of concrete batching.

3. Excavation and mining: often used to process and transport sand from ores. They can help transport sand from the mining site to processing equipment or storage areas.

4. Environmental protection projects: Sand screw conveyors are also widely used in environmental protection projects, such as soil remediation, wastewater treatment, etc.

5. Glass manufacturing: used to transport sand to glass kilns or other production equipment to ensure the smooth progress of the production process.

Working Principle

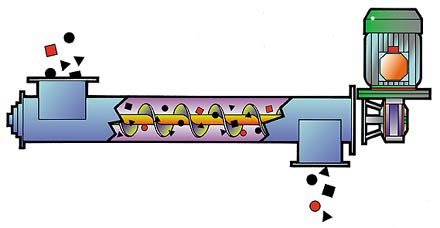

The working principle of the screw conveyor for sand is to use the rotation of the screw blade to push the material to move along the direction of the pipeline. When the conveyor starts, the motor drives the screw blades to rotate, and the material moves forward in the pipeline due to its own gravity and the push of the screw blades. During the movement, the material continuously rubs against the spiral blade and the pipe wall in the conveyor, so as to achieve the purpose of conveying the material. Finally, the material is discharged from the discharge port.

Advantages

Versatility: They can be used for both short-distance and long-distance conveying, and can handle various types of sand.

Efficiency: Screw conveyors provide a continuous and reliable flow of sand, minimizing downtime and maximizing productivity.

Flexibility: They can be easily integrated into existing systems or customized to fit specific process requirements.

Compact Design: Screw conveyors have a compact footprint, making them suitable for installations where space is limited.

Minimal Maintenance: With proper design and maintenance, screw conveyors for sand can operate reliably with minimal downtime.

Videos

Technical Parameters

| Model |

Spiral diameter (mm) |

Screw-pitch (mm) |

Speed (r/min) |

Capacity (m³/h) |

| LS-100 | 100 | 100 | 140 | 2.2 |

| LS-160 | 160 | 160 | 112 | 7 |

| LS-200 | 200 | 200 | 100 | 13 |

| LS-250 | 250 | 250 | 90 | 22 |

| LS-315 | 315 | 315 | 80 | 31 |

| LS-100 | 100 | 355 | 71 | 56 |

| LS-500 | 500 | 400 | 63 | 98 |

| LS-630 | 630 | 450 | 50 | 140 |

| LS-800 | 800 | 500 | 40 | 300 |

| LS-1000 | 1000 | 560 | 32 | 280 |

| LS-1250 | 1250 | 630 | 25 | 380 |

When selecting a screw conveyor for handling sand, several factors need to be considered:

1.Capacity: Determine the required capacity or throughput of sand that needs to be conveyed. This will help in determining the size and specifications of the screw conveyor.

2.Length and Incline: Consider the distance the sand needs to be conveyed and whether there are any inclines or changes in elevation. Longer distances or steep inclines may require additional considerations such as intermediate hanger bearings or specialized designs.

3.Design and Construction: The screw conveyor should be designed to handle sand effectively. It should have a suitable screw pitch, diameter, and trough size to accommodate the characteristics of sand, such as particle size, density, and flowability.

4.Material of Construction: Depending on the application and the type of sand being conveyed, the screw conveyor can be constructed using various materials, such as carbon steel, stainless steel, or abrasion-resistant alloys. Consider the corrosiveness or abrasiveness of the sand and select the appropriate material for longevity and durability.

5.Drive System: Determine the power source and drive mechanism for the screw conveyor. Common options include electric motors, hydraulic drives, or gear reducers. The drive system should be capable of providing sufficient power to move the sand efficiently.