Sludge Screw Conveyor

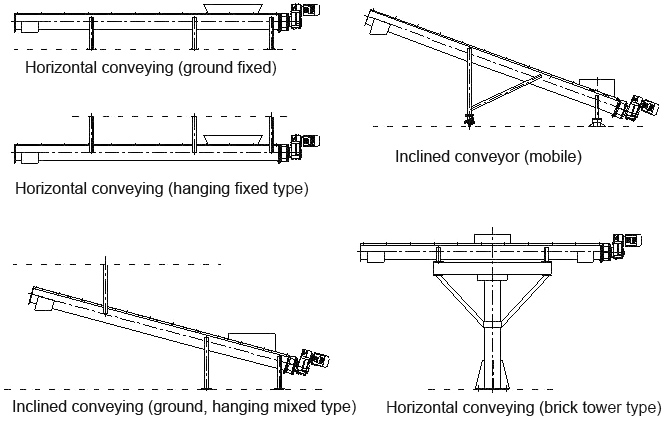

It is specially used to transport sludge in sewage treatment plants. It adopts a center-axis-less design. The sludge is not easy to stick to the spiral blades or agglomerate. It can be installed horizontally or tilted.

Diameter: 150 - 470 mm

Inclination of installation: 0-15° or 0-30°

Length: 0-20 mt or 0-30 mt

Capacity: from 0.8 mc/h to 45 mc/h

Application: Field of use: Sewage treatment plant transports medium and fine screen decontamination machine screen residue and sludge dewatered mud cake, etc.

Product Introduction of Sludge Screw Conveyor

Sludge screw conveyor is a specialized type of screw conveyor designed to handle and transport various types of sludge efficiently. Sludge, which is a semi-solid residue produced during wastewater treatment processes, can be challenging to handle due to its sticky, viscous, and abrasive nature. Sludge screw conveyors play a crucial role in the wastewater treatment industry by effectively moving sludge from one point to another within treatment facilities.

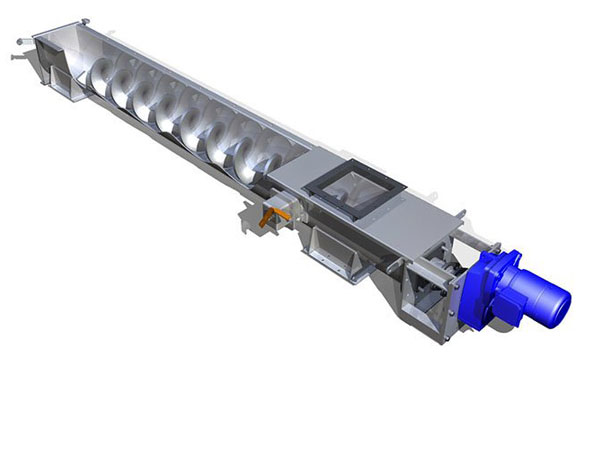

The sludge screw conveyor consists of a rotating screw or auger enclosed in a trough or tube. As the screw rotates, it moves the sludge along the length of the conveyor. The design of the screw and the trough is tailored to handle the specific characteristics of sludge, such as its viscosity, moisture content, and particle size.

Application of Sludge Screw Conveyor

1.Wastewater Treatment: In wastewater treatment plants, sludge screw conveyors are used to transport sludge from different treatment processes. They are commonly used to transfer sludge from sedimentation tanks, clarifiers, or thickeners to dewatering equipment such as belt filter presses, centrifuges, or sludge drying beds.

2.Sludge Dewatering: Sludge screw conveyors play a crucial role in sludge dewatering processes. After the dewatering equipment removes water from the sludge, the screw conveyor is used to transport the dewatered sludge to storage or disposal areas. This helps in reducing the moisture content and volume of the sludge, making it easier to handle and dispose of.

3.Sludge Storage and Disposal: Sludge screw conveyors are used to transport sludge to storage containers or trucks for further treatment, disposal, or transport to off-site facilities. They ensure a continuous and efficient flow of sludge, facilitating proper management and disposal of the waste material.

4.Industrial Processes: Sludge screw conveyors are also employed in various industrial processes where the handling and transport of sludge or other viscous materials are required. Industries such as food processing, chemical manufacturing, and mining often use sludge screw conveyors to move materials between processing stages or for waste management purposes.

Video

Sludge Screw Conveyor application advantages

1. There is no central shaft, the screw torque is increased, the driving force of the screw is enhanced, and the conveying capacity is increased.

2. The thickened design of the blade is not easy to twist, has strong anti-winding and anti-sticking properties, and does not block materials.

3. Multiple inlets and outlets can be designed to be used with multiple sludge inlets, and multiple Sludge Screw Conveyors can be connected.

4. The gasket cover design can be opened and closed, and the internal conveying situation can be checked at any time, and the residual Sludge can be cleaned in time to avoid blockage.

Sludge Screw Conveyor Structural Design

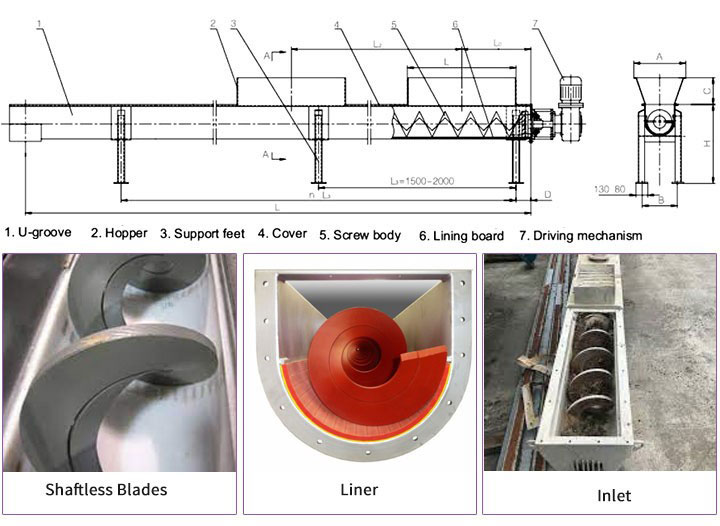

Sludge Screw Conveyor is mainly composed of driving device, head assembly, casing, screw body, tank liner, inlet, outlet, cover (if necessary), base, etc.

1. Driving device: Cycloidal pin wheel reducer or shaft-mounted hard-toothed gear reducer is used. The driving device should be set at the discharge port as much as possible during design, so that the sludge can be subjected to stronger pressure during the transportation process. pull.

2. Spiral blades: The blades of Sludge Screw Conveyor are shaftless spiral blades, which make the sludge conveying more smoothly without blocking the material. If the service life is considered, it is recommended to use the spiral conveying blades processed by high-strength wear-resistant steel.

3. Shell: "U"-shaped trough, with a rain-proof cover on the upper part to prevent sludge from leaking out.

4. Lining plate of the tank body: It is made of high-strength engineering plastic polymer polyethylene, which has weak adsorption, and the sludge is not easy to adhere, and is resistant to wear and corrosion.

5. Inlet and outlet: There are two types of square and round. Generally, the form and quantity of inlet and outlet are determined by the user.

Technical parameters

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

How to choose a Sludge Screw Conveyor?

1. Model: Sludge screw conveyor models include WLS100, WLS160, WLS200, WLS250, WLS315, WLS400, WLS500, WLS630, WLS800, WLS1000, WLS1250, etc. The corresponding conveying capacity is 2.2m³/h, 7.6m³/h, 11m³ /h, 22m³/h, 36.4m³/h, 66.1m³/h, 93.1m³/h, 160m³/h, 223m³/h, 304m³/h, 458m³/h; different models correspond to different conveying volumes, you can customize it according to your own needs Select the model according to the desired conveying capacity.

2. Material: There are two types of materials: carbon steel and stainless steel. The carbon steel sludge screw conveyor has high strength, but is easy to corrode: the stainless steel sludge screw conveyor uses high-content alloy steel, which has good corrosion resistance and is not easy to rust.

3. Installation method: There are ground fixed type, hanging type, and ground and hanging mixed type. You can choose according to the venue.

Solutions by Industry