Stainless Steel Screw Conveyor

Made of stainless steel for corrosion resistance and durability, it is commonly used in industries such as food processing, pharmaceuticals, chemicals and wastewater treatment.

Material: 304 stainless steel/316L stainless steel

Spiral diameter: 100-1250mm

Conveying length: 2-20 meters

Conveying capacity: 142m³/h

Speed: 60 rpm

Introduction of Stainless Steel Screw Conveyor

Stainless steel screw conveyor is made of 304 or 316 stainless steel, designed for food or pharmaceutical industries. Washable and sterilizable, resistant to corrosion and avoiding material contamination, it provides a variety of solutions for conveying or feeding powdery or granular materials. They are suitable for applications where any contamination of the material handled must be strictly avoided and where absolute cleanliness and perfect corrosion resistance are required, such as in environmental technology, flour and animal feed processing, food processing and packaging, plastics and chemicals, and the pharmaceutical industry.

Optional Material of Stainless Steel Screw Conveyor

Stainless steel screw conveyors are commonly used in various industries for transporting bulk materials, such as grains, powders, and chemicals. Here are some optional materials that can be used for stainless steel screw conveyors:

304 Stainless Steel: 304 stainless steel is a common material used for screw conveyors. It is a low-carbon stainless steel that is resistant to corrosion and can withstand high temperatures. 304 stainless steel is suitable for most applications and is a cost-effective option.

316 Stainless Steel: 316 stainless steel is a higher grade of stainless steel that is more resistant to corrosion than 304 stainless steel. It is suitable for applications where the screw conveyor will be exposed to harsh chemicals or environments. 316 stainless steel is more expensive than 304 stainless steel.

Video

Application of Stainless Steel Screw Conveyor

Stainless steel screw conveyors are widely used in many industries. Because stainless steel has good corrosion resistance and hygienic properties, it is suitable for many occasions that need to handle sensitive materials or require high hygienic standards. The following are common applications for stainless steel screw conveyors:

1. Food processing: Stainless steel screw conveyors are widely used in the food processing industry. They are used to transport powdered, granular and flake food ingredients such as flour, cereals, sugar, cocoa powder, vegetables and fruits, etc. Since stainless steel has good hygienic properties and is easy to clean, they ensure food safety and hygiene.

2. Pharmaceutical industry: In the pharmaceutical industry, stainless steel screw conveyors are used to transport pharmaceutical raw materials such as powders, granules, capsules and tablets. They meet the strict hygiene standards of the pharmaceutical industry and are easy to clean and disinfect, ensuring product quality and safety.

3. Chemical industry: Due to the corrosion resistance of stainless steel, stainless steel screw conveyors are widely used in the chemical industry to transport various chemical substances, including powders, granules, liquids and slurries. They can be used to transport chemicals, fertilizers, plastic granules, pigments, coatings and solvents, etc.

4. Environmental protection projects: Stainless steel screw conveyors are used to treat wastewater, sludge and solid waste in environmental protection projects. They transport waste from treatment equipment to storage facilities or treatment sites, ensuring efficient waste treatment and reducing environmental pollution.

Advantages of Stainless Steel Screw Conveyor

1. Clean and hygienic: The 304 or 316 stainless steel material is polished and will not rust, which can avoid pollution to the conveyed materials and the environment.

2. Acid and alkali corrosion resistance: Due to the use of 304 or 316 stainless steel, it has good wear resistance and corrosion resistance, and can be used in industries with strong acid and alkali.

3. 200℃ high temperature resistance: It can transport dry powder and wet powder such as 200℃ powder, granule and small block materials.

4. Easy to clean: There is a discharge valve at the lower end of the feeding port, and the screw can be reversed to discharge, so the discharge and cleaning are very convenient.

5. Various soft connections: The inlet and outlet can be connected by universal joints, cloth bags and flanges, and can also be combined with butterfly valves and plug-in valves produced by our factory, which can be flexibly applied to sewage in grain, chemical, pharmaceutical, food or environmental protection projects. Sludge treatment site.

6. Sealing system: The completely sealed environment has great advantages for occasions with large dust and environmental requirements, which can avoid the generation of dust during the conveying process.

Technical Parameter of Stainless Steel Screw Conveyor

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

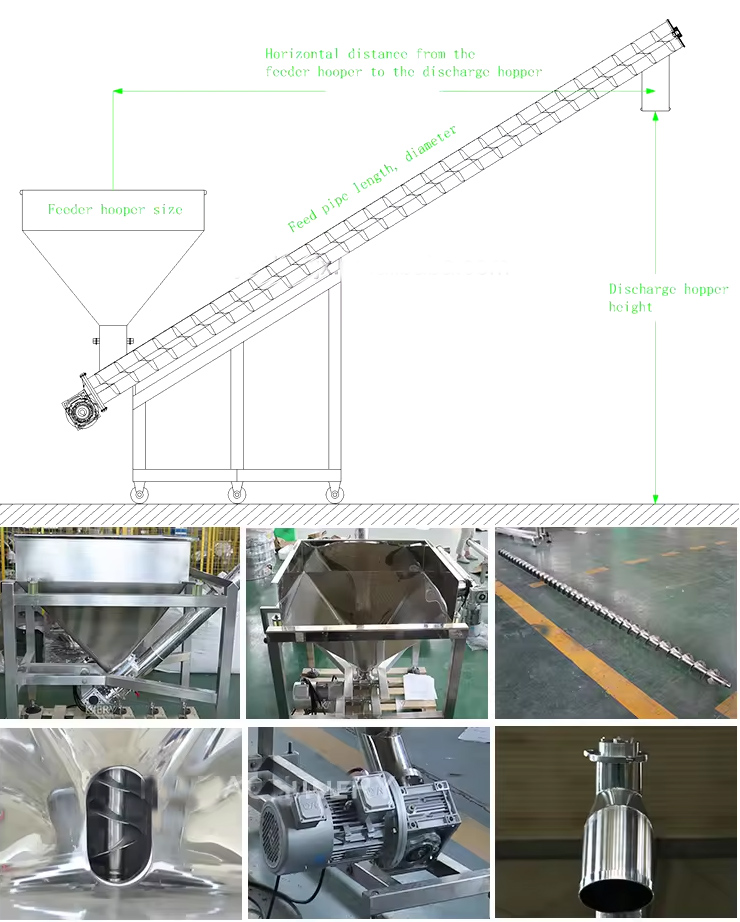

Structure and Details of Stainless Steel Screw Conveyor

Spiral: It is usually made of stainless steel and designed in a spiral shape that allows the screw to convey material from one end to the other. Screw pitch, diameter and length can be customized according to specific application requirements.

Tube: The tube is the casing that surrounds the screw. It is usually made of stainless steel and can be designed in various shapes and sizes according to specific application requirements.

Drive system: It usually consists of a motor, gearbox and coupling. The motor provides the power to turn the screw, while the gearbox and coupling help transmit the power from the motor to the screw.

Inlet and outlet: The inlet and outlet are the openings at both ends of the screw conveyor. The feed port is used to feed the material into the screw conveyor, and the discharge port is used to discharge the material from the screw conveyor.

Hanger Bearings: Hanger bearings are used to support the screw and prevent it from bending or deflecting. They are usually made of stainless steel and can be designed in various shapes and sizes according to specific application requirements.

Seals: Seals are used to prevent leakage of material from the screw conveyor. They are usually made of rubber or another flexible material and sit at the end of the tube.

Stainless Steel Screw Conveyor Manufacturers

The material of Xinxiang Dahan stainless steel screw conveyor is divided into 304 and 316L stainless steel. The appropriate material can be selected according to the conveyed material. It is mostly used in industry, food and pharmaceutical industries. Shuzhong Pharmaceutical Co., Ltd., Shanghai Jiage Food Co., Ltd., Sunflower Pharmaceutical Group, Coca-Cola, etc. In addition, our conveyors can also be customized according to customer's on-site requirements, such as: lengthened design, different inclination angles, the size of the feed inlet, the addition of a hopper at the feed inlet, and the installation of moving wheels, etc.