Stone Screw Conveyor

Is a conveyor used for transporting bulk materials such as sand, gravel, gravel and other similar materials.

Conveying length: 10-20 meters

Output: 134 m³/h

Slot width: 200-600mm

Inclination: ≤15°

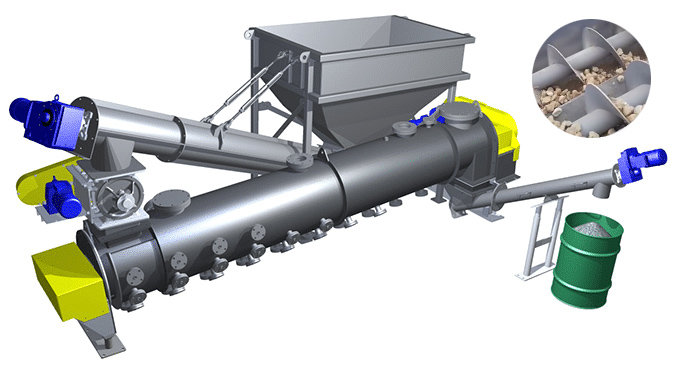

Stone screw conveyor, also known as an aggregate screw conveyor, is a type of conveyor that is used to transport bulk materials such as sand, gravel, crushed stone, and other similar materials. It is a versatile piece of equipment that can be used in a variety of industries, including construction, mining, and agriculture.

The stone screw conveyor is designed to handle heavy-duty and abrasive materials such as stones, gravel, sand, and other solid particles. It is commonly used in industries such as mining, construction, agriculture, and bulk material handling. The conveyor system can be customized in terms of length, diameter, and pitch of the screw to accommodate specific material handling requirements.

Uses of Stone Screw Conveyor

Stone screw conveyors have many uses in the industrial field, mainly including the following aspects:

1. Mining: In mines and mining sites, it is used to transport materials such as ore, coal, ore, and help improve production efficiency.

2. Construction industry: On construction sites, it is often used to transport concrete, stone, sand and other construction materials, and is used in concrete mixing stations and other construction processes.

3. Metallurgical industry: In metallurgical production, Stone Screw Conveyors can be used to transport raw materials such as ore and metal powder, as well as transport molten metal or other metallurgical products.

Videos

Working Principle of Stone Screw Conveyor

The working principle is that when the screw conveyor is started, the motor transmits power to the screw shaft through the transmission device, so that the screw blades rotate, thereby pushing the stones forward. During the movement, the stone will be pushed forward by the thrust and gravity of the spiral blade, and finally transported to the target position through the conveying pipeline.

Advantages of Stone Screw Conveyor

Enclosed Design: The stone screw conveyor is completely enclosed to help prevent dust and spills. This makes them ideal for use in environments where dust control is required.

Versatility: Stone screw conveyors can be used to convey a variety of bulk materials, including sand, gravel, crushed stone, and other similar materials.

Durability: Stone screw conveyors are made of wear-resistant materials, which makes them durable and long-lasting.

Efficiency: Stone screw conveyors are a very efficient way to transport bulk materials. They require relatively little electricity to operate and can move large amounts of material quickly.

Easy to install: Stone screw conveyors are relatively easy to install and can be configured to meet the specific needs of a particular application.

Technical Parameters

| Specification | Technical performance | Drive | Drive | Weight (kg) | |||

| Diameter | Length (m) | Output (t/h> | Speed (min) | Reducer | Electric motor | ||

| Model | Speed ratio | Power(kw) | |||||

| U 200 | -10 | 9 | 60 | ZQ250 | 23.34 | 1.1 | 726 |

| U 200 | -20 | 9 | 60 | ZQ250 | 23.34 | 1.5 | 1258 |

| U 250 | -10 | 15.6 | 60 | ZQ250 | 23.34 | 2.2 | 960 |

| U 250 | -20 | 15.6 | 60 | ZQ250 | 23.34 | 3 | 1750 |

| U 300 | -10 | 21.2 | 60 | ZQ350 | 23.34 | 3 | 1373 |

| U 300 | -20 | 21.2 | 60 | ZQ350 | 23.34 | 4 | 2346 |

| U 400 | -10 | 51 | 60 | ZQ400 | 23.34 | 5.5 | 1911 |

| U 400 | -20 | 51 | 60 | ZQ500 | 23.34 | 11 | 2049 |

| U 500 | -10 | 87.5 | 60 | ZQ400 | 23.34 | 7.5 | 2381 |

| U 500 | -20 | 87.5 | 60 | ZQ650 | 23.34 | 18.5 | 5389 |

| U 600 | -10 | 134.2 | 45 | ZQ750 | 23.34 | 22 | 3880 |

| U 600 | -10 | 134.2 | 45 | ZQ850 | 23.34 | 55 | 7090 |

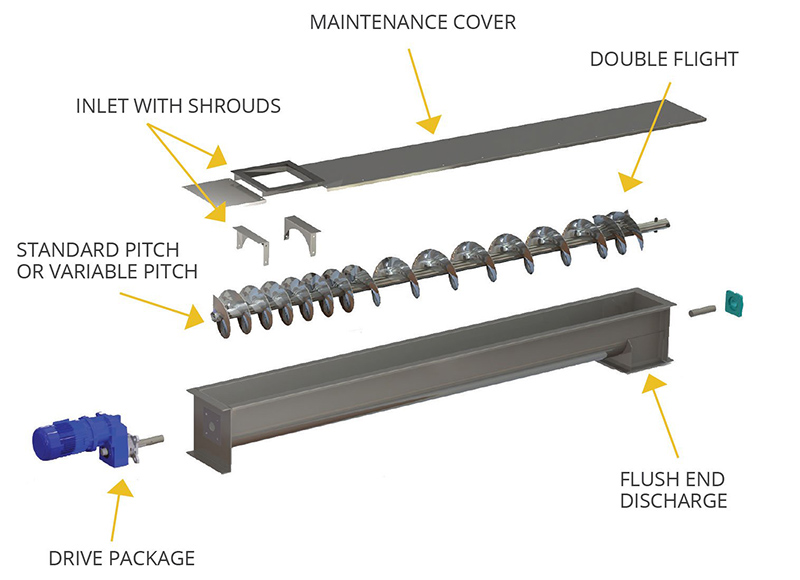

Structure of Stone Screw Conveyor

1. Screw shaft: The screw shaft is the core part of the conveyor, usually made of steel pipe or steel plate. It is located in the center of the conveyor and drives the entire conveyor to run through the transmission device.

2. Helical blade: The helical blade is located on the helical shaft and has a helical shape.

3. Reducer: The reducer is usually installed at one end of the screw shaft to reduce the speed of the transmission to match the speed of the conveyor.

4. Inlet and outlet: The inlet is used to introduce materials into the conveyor, while the outlet is used to discharge materials out of the conveyor.

5. Support frame: The support frame is used to support the main part of the conveyor.

6. Transmission device: The transmission device is used to drive the operation of the screw shaft and the conveyor. It usually consists of a motor, a coupling and a belt.

7. Operating system: It usually consists of an electrical control cabinet and an operation panel, which can be manually or automatically controlled as required.