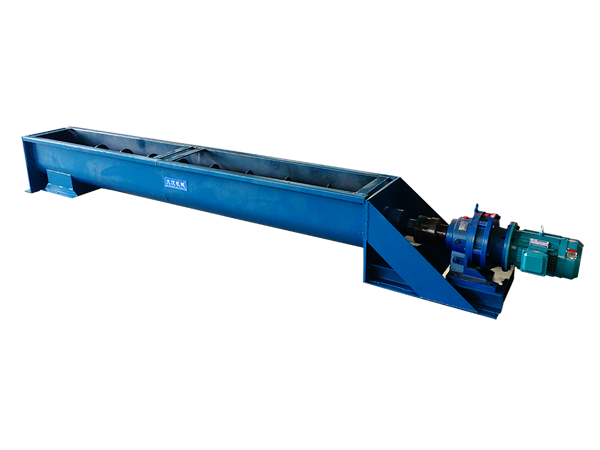

U type screw conveyor

Consisting of a U-shaped trough or channel and a rotating screw or auger that moves material along the length of the trough, it is capable of handling a wide variety of materials, including powders, granules, sticky or abrasive materials. They are commonly used in industries such as food processing, chemical manufacturing and mining to transport materials such as grain, sugar, cement and coal.

Type: Shafted or Shaftless

U-shaped slot width: 200, 250mm, 300mm, 400mm, 500mm, 600mm

Conveying length: 10-20 meters

Conveying length: 9-134t/h

Optional material: Q235 carbon steel, SUS304 or 316L stainless steel

product description

U type screw conveyor, also known as a trough screw conveyor, is a type of conveyor system used for the transportation of bulk materials. It consists of a U-shaped trough or channel and a rotating screw or auger that moves materials along the length of the trough.

The U-shaped trough is typically made of steel or stainless steel and is designed to enclose the material being transported. The screw or auger is a helical blade that is mounted on a shaft and rotates inside the trough. As the screw rotates, it moves material along the length of the trough.

U type screw conveyors are well suited for transporting bulk materials because they can be customized to meet the specific needs of different applications. They can be designed to transport materials horizontally or vertically, and can be equipped with various features such as feeders, hoppers, and discharge valves. They can also be designed to operate at different speeds and capacities, depending on the requirements of the application.

Applications

U type screw conveyor can be divided into two types: shaft and shaftless. The shaft type is suitable for non-viscous dry powder materials and small particle materials (such as: cement, fly ash, lime, grain, etc.); while the shaftless U type screw conveyor is suitable for conveying viscous and easily entangled materials (for example: sludge, biomass, garbage, etc.). U type screw conveyor is usually used in the field of environmental protection, recycling and sewage treatment.

U type screw conveyors are used in a wide range of applications across various industries. Here are some common applications of U type screw conveyors:

Food Processing: Used in the food processing industry to convey materials such as grain, sugar, flour and other dry food ingredients. They are designed with food-grade materials, are easy to clean, and are suitable for hygienic applications.

Chemical manufacturing: used for conveying powder, granular, pellet and other materials in the chemical manufacturing industry. They can be designed with corrosion-resistant materials and can handle abrasives.

Mining industry: used in the mining industry to transport coal, ore, minerals and other materials. They can be designed to handle heavy loads and can be customized to operate in harsh environments.

Waste treatment: Used in waste treatment facilities to transport materials such as sludge, wastewater and other waste. They can be designed to handle large volumes of material and can be equipped with features such as screens and filters to remove contaminants.

Agriculture: Used in agriculture to convey materials such as grain, seeds and fertilizers. They can be customized to handle different types of materials and can be designed to operate in outdoor environments.

Product advantages

Larger Capacity: Larger conveying capacity than other types of screw conveyors, making them ideal for high-volume applications.

Versatility: Can handle a variety of materials including powders, granules and flakes, making it a versatile choice for many industries.

Reduced Material Degradation: U type design reduces material degradation, which can be a problem when conveying fragile or easily damaged materials.

Reduced Wear: U type screw conveyors wear less than other types of screw conveyors because the design reduces the amount of contact between the screw and the trough.

Low Noise Levels Operating noise levels are lower than other types of screw conveyors, an important consideration when working in noise-sensitive environments.

Easy Maintenance: Easy maintenance and cleaning helps reduce downtime and increase productivity.

product structure

U type screw conveyor is mainly composed of driving device, head assembly, casing, spiral body, slot liner, inlet, outlet, cover (if necessary), base, etc.

1. Transmission device: Cycloidal pinwheel reducer or shaft-mounted hardened gear reducer. When designing, the driving device should be installed at the end of the discharge port as much as possible, so that the screw body is in a tensioned state during operation.

2. The machine head is equipped with a thrust bearing, which can withstand the axial force generated when conveying materials.

3. Spiral blade: the general material is stainless steel or carbon steel. Considering the service life, it is recommended to use high-strength wear-resistant steel screw conveyor blades.

4. Conveying trough: It is a "U"-shaped trough with a rainproof cover on the upper part, and the material is stainless steel or carbon steel or glass steel.

5. Tank liner: made of high-strength engineering plastic polymer polyethylene, which has the characteristics of weak adsorption, non-stick material, wear resistance and corrosion resistance, and is used to avoid wear of the pipe tank wall.

6. Water inlet and outlet: There are two types: square and round. The general import and export forms are determined by the user.

Product number

| Specification | Main technical performance | Drive device | Drive device | Weight(kg) | |||

| Diameter | Length(m) | Yield( t/h) | Rotating speed(min) | Reducer | Electric motor | ||

| Model | Speed ratio | Power(kw) | |||||

| U 200 | -10 | 9 | 60 | ZQ250 | 23.34 | 1.1 | 726 |

| U 200 | -20 | 9 | 60 | ZQ250 | 23.34 | 1.5 | 1258 |

| U 250 | -10 | 15.6 | 60 | ZQ250 | 23.34 | 2.2 | 960 |

| U 250 | -20 | 15.6 | 60 | ZQ250 | 23.34 | 3 | 1750 |

| U 300 | -10 | 21.2 | 60 | ZQ350 | 23.34 | 3 | 1373 |

| U 300 | -20 | 21.2 | 60 | ZQ350 | 23.34 | 4 | 2346 |

| U 400 | -10 | 51 | 60 | ZQ400 | 23.34 | 5.5 | 1911 |

| U 400 | -20 | 51 | 60 | ZQ500 | 23.34 | 11 | 2049 |

| U 500 | -10 | 87.5 | 60 | ZQ400 | 23.34 | 7.5 | 2381 |

| U 500 | -20 | 87.5 | 60 | ZQ650 | 23.34 | 18.5 | 5389 |

| U 600 | -10 | 134.2 | 45 | ZQ750 | 23.34 | 22 | 3880 |

| U 600 | -10 | 134.2 | 45 | ZQ850 | 23.34 | 55 | 7090 |

Video

Industry Solutions

1. Conveying bulk powder or particles horizontally or at a small inclination

U type screw conveyor is very suitable for conveying materials at horizontal or small inclined angles. U type screw conveyor with shaft design is widely used in food, medicine, heavy industry and other industries.

2、garbage collection

U type screw conveyor has a good effect when it is used to convey viscous, easily agglomerated and clogged household garbage, industrial garbage or kitchen garbage, and there is no need to worry about belt-shaped or silky garbage being entangled and clogged.

3. Sewage treatment

The shaft-designed U type screw conveyor is used to transport sludge with high water content or inclined transport.

The U type screw conveyor with shaftless design is the best choice for conveying viscous dewatered sludge. The design without a central shaft can avoid sludge clogging, and the thickened spiral design will not break the spiral due to excessive conveying resistance.