Auger Conveyor

Auger conveyor is a mechanism that uses a rotating helical screw blade, called a "flighting", usually within a tube, to move liquid or granular materials. Usually used horizontally or slightly inclined, can also be arranged vertically.

Auger diameter: 100mm-600mm

Length: 2-20meters (Can be customized)

Conveying angle: 0-90°

Application: It can efficiently and continuously convey powder, granular and small block materials in horizontal or inclined conditions. It is widely used in agriculture, construction, mining, food processing, chemical industry and waste treatment industries.

Introduction of Auger Conveyor

Auger conveyors can transport powder and granular materials from one machine to another. It can be combined with the packaging machine to form a production line. Therefore, it is widely used in packaging lines, especially semi-automatic and automatic packaging lines. Mainly used for conveying powdery materials, such as milk powder, protein powder, rice flour, milk tea powder, essence, spices, etc.

When the auger conveyor is working, the screw shaft rotates, and the material moves forward along the groove bottom of the conveyor under the push of the blade. Due to the gravity of the material and the friction between the material and the groove wall, the material does not rotate with the blades of the auger conveyor, and the transportation of the material in the conveyor is a kind of sliding.

Types of Auger Conveyor

1、Shafted auger conveyor: When conveying loose and granular materials, the conveying capacity is strong, and the material is not slippery.

2、Shaftless auger conveyor: It can prevent the material from being entangled and blocked, and can be used to transport waste, viscous sludge, fabrics, etc.

3、Inclined auger conveyor: Conveying with an angle to lift the material to a certain height.

4、Vertical auger conveyor: Completely vertical conveying, stronger motor power and more compact structure, strong lifting capacity and occupy less space.

5、Double auger conveyor: The conveying capacity is 1.5 to 2 times that of the single-shaft auger conveyor.

What is the Operation of Auger Conveyor?

The operation of an auger conveyor, also known as a screw conveyor, involves the following steps:

Material Loading: The material to be transported is loaded into the inlet of the conveyor. This can be done manually or through an automated feeding system depending on the setup.

Rotation of the Auger: The main component of the auger conveyor is the screw-like auger within a tube. This auger rotates, usually driven by an electric motor, causing the material to move along the length of the conveyor.

Material Transport: As the auger rotates, the helical flighting or blades of the auger push the material along the tube. The design of the auger flighting determines how the material is moved—whether by pushing or pulling.

Discharge: The material reaches the discharge end of the conveyor where it is released. This can be into a hopper, another conveyor, a processing machine, or any other designated location.

Features and Benefits

Wide applicability: Auger conveyors are suitable for a variety of materials, including granules, powders, granule mixtures, etc., making them widely used in different industries and applications.

Flexible conveying methods: It can realize horizontal conveying, can carry out inclined conveying at a certain angle, realize the lifting or lowering of materials, and in some special cases, can carry out vertical conveying.

Good sealing: The compact structure and good sealing can effectively prevent material leakage and reduce dust pollution. It is suitable for harsh environments and can be used in harsh environments such as high temperature and high humidity to ensure the safety of the conveying process.

Adjustable conveying capacity: The conveying capacity can be adjusted by adjusting the speed to achieve precise control of the production process.

Small footprint: Screw conveyors usually occupy a small area and can be flexibly installed in limited spaces, which is suitable for workplaces with limited space.

High degree of automation: It can be integrated with other equipment to realize automated production lines and improve production efficiency and automation level.

Video

Technical parameters

There are many types of auger conveyors. If you have special needs, Dahan will provide you with customized services for free.

| Model | LS114 | LS133 | LS159 | LS219 | LS245 | LS273 | LS315 | LS400 | LS500 | LS600 |

|

Diameter (mm) |

114 | 133 | 159 | 219 | 245 | 273 | 315 | 400 | 500 | 600 |

|

Rated speed (r/min) |

84- 130 | 84-130 | 84-130 | 84-130 | 84-130 | 84-130 | 84-130 | 62-100 | 62-100 | 62-100 |

|

Reference capacity (m³/h) |

1 | 1.3 | 5 | 15 | 20 | 30 | 40 | 45 | 70 | 100 |

|

Motor power (Kw) |

2.2-18.5 | |||||||||

|

Admission biggest gradient (o) |

<60 | |||||||||

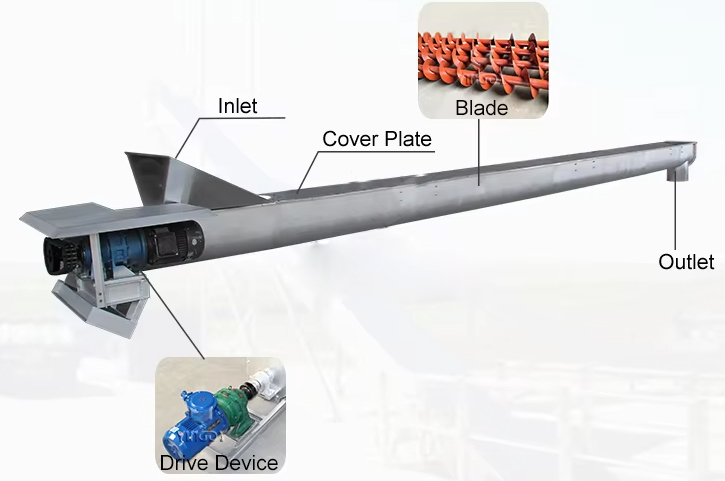

Auger Conveyor structure

An auger conveyor consists of several key components, each playing a crucial role in its operation. Here are the main parts:

Screw (Auger): The helical blade that moves the material along the conveyor. Its design can vary based on the type of material being transported.

Housing: The outer casing that contains the screw and helps direct the flow of material. It can be made from various materials depending on the application.

Drive Unit: The motor and gearbox that provide the necessary power to rotate the screw. This unit is essential for the movement of the material.

Inlet: The opening where the material is loaded into the conveyor. It can be designed for various feeding methods.

Discharge Outlet: The point where the material exits the conveyor. It can be adjustable to control the flow rate.

Support Legs: Structures that support the conveyor and maintain its stability during operation.

End Bearings: Bearings located at both ends of the screw to allow smooth rotation and support the screw shaft.

Screw Shaft: The central shaft that the screw is mounted on, providing the rotational force.

Seals and Covers: Components that help contain the material within the housing and prevent dust or spillage.

Application

Auger conveyor is widely used in many industries. Here are some specific application scenarios:

Food processing industry: used to transport food raw materials, finished products, packaging materials, etc., such as candy, vegetables and other food production lines.

Grain processing industry: used to transport raw materials or finished products such as grains, seeds, flour, etc., usually appearing in grain storage, grinding workshops and other process links.

Chemical and pharmaceutical industries: used to transport powdered materials, granular materials, granular mixtures, etc., such as fertilizers, pharmaceutical raw materials, etc.

Building materials industry: used to transport cement, sand, gravel and other building materials, commonly seen in concrete mixing plants, sand and gravel yards and other construction sites.

Waste disposal: used to transport garbage, waste materials, recycled materials, etc., which helps to achieve waste classification and treatment.

Mining and metallurgical industry: used to transport ore, slag, coal and other materials to help realize the extraction and processing of ore.

Solutions by Industry

Auger Conveyor used in industry, recycling and environmental protection Auger Conveyor used in industry, recycling and environmental protection

Auger Conveyor for food, agriculture, medicine Auger Conveyor for food, agriculture, medicine