Auger Feeder

It is mainly used to transport powdery, granular or small block materials from storage bins or hoppers to the next process evenly and continuously.

Tilt angle: 0-90 degrees

Length: ≤10 meters

Carrying capacity: 100-8000 kg/hour

Material: carbon steel, stainless steel or plastic

Application: Used for conveying bulk materials in feed, chemical, food processing, grain processing, grain storage, various additives, construction engineering and other industries.

-

What is an auger feeder?

Auger feeder can automatically feed powdered, granular and flake raw materials directly into the hopper. All parts in contact with the materials are made of stainless steel. The raw materials are completely free from contamination and foreign matter during transportation, which can realize fully closed automation of the production process.

Auger feeder can be used alone or directly connected and fixed with its supporting equipment, such as vibrating screen, mixer, packaging machine, etc. It can be divided into stainless steel and carbon steel according to the material, and the feed opening can be customized into round or square.

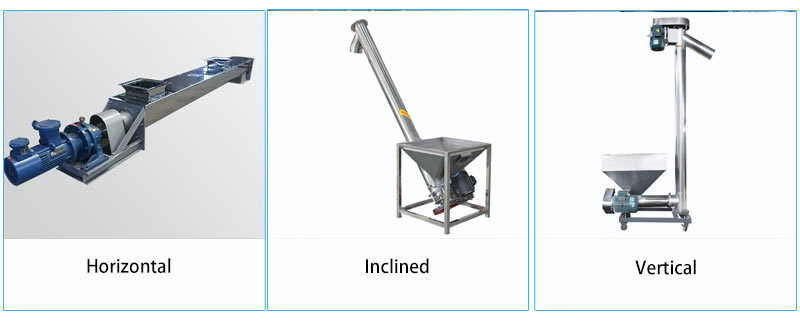

Types of auger feeder

Horizontal auger feeder: used for continuous and uniform conveying of loose materials at a horizontal or slightly inclined position (less than 20°), and the conveying distance is generally not more than 20 meters.

Inclined auger feeder: used for conveying materials within a range of 60°, and the conveying length can reach 10 meters.

Vertical auger feeder: conveys materials vertically upward at 90°, with a higher speed than ordinary screw conveyors, and the lifting height is generally not more than 4 meters.

How does the auger feeder work?

Material Loading: Bulk material is loaded into the hopper. The hopper is designed to allow gravity to feed the material into the auger.

Feeding Mechanism: As the auger screw rotates, it creates a pushing action that moves the material along the screw’s length. The design of the screw (pitch, diameter) determines how efficiently the material is transported.

Material Movement: The rotation of the auger creates a continuous flow of material. As the screw turns, it lifts the material upward or horizontally, depending on the auger's orientation.

Discharge: The material exits the auger feeder through the discharge outlet at a controlled rate. The speed of the auger can often be adjusted to regulate the flow of material.

Videos

Features

Uniform conveying: It is not easy to block and jam during the material conveying process, and the feeding is uniform and stable.

Dust-free: The sealing effect is good, dust-proof and pollution-proof, and it can isolate materials with strong odor and easy to raise dust, and improve the working environment.

Flexible layout: It can be installed horizontally, and it can also adapt to angled working conditions. It can even achieve vertical conveying, replacing the hoist to save production costs.

Long service life: It adopts external imported bearings, and the bearings contain sealing pads to prevent dust from entering the bearings and extend the service life.

Easy to clean: In order to facilitate the cleaning of waste materials, the machine is designed to: reverse discharge, store the material at the bottom of the hopper tube, and take out the entire screw.

Technical parameters

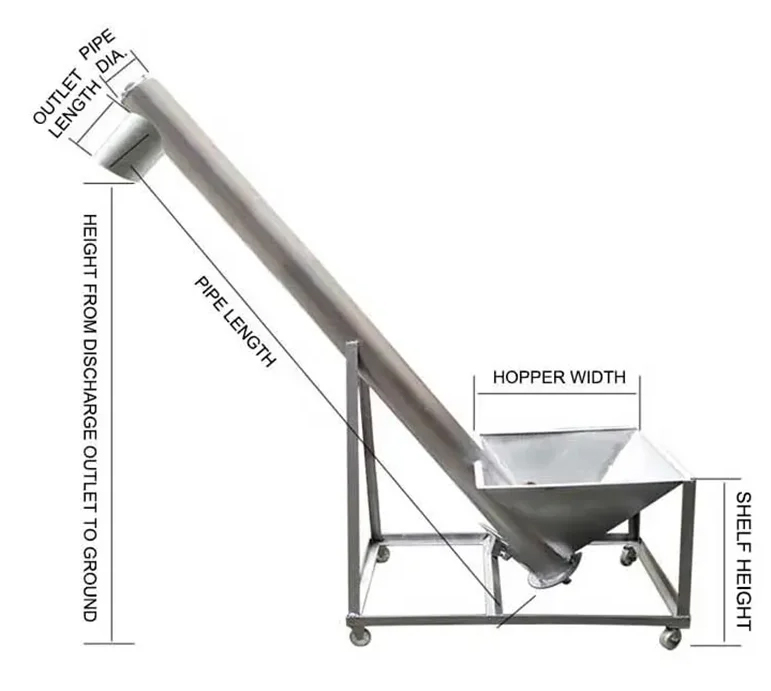

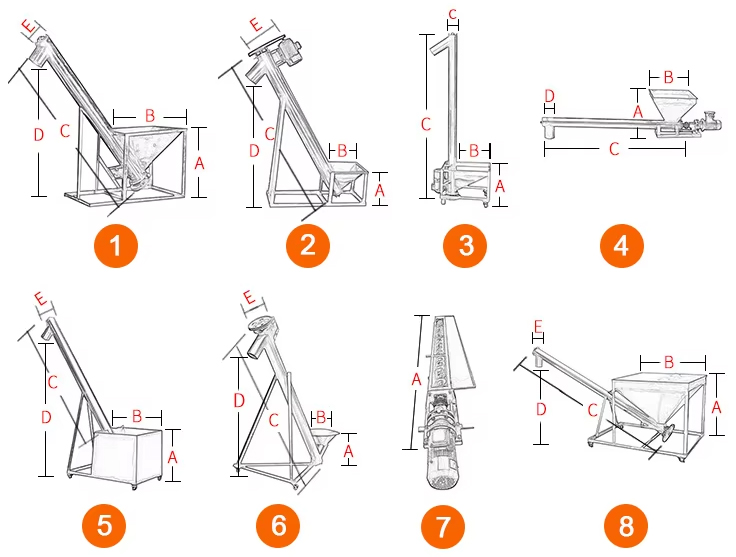

Dahan Machinery can provide a variety of auger feeders, if you need, the equipment can be customized according to your requirements.

| WLS type | Screw pitch(mm) | Rotation speed(r/min) | Transportation volume QΦ=0.33(m3/h) |

| 100 | 100 | 120 | 1.9 |

| 160 | 160 | 90 | 5.7 |

| 200 | 200 | 75 | 18 |

| 250 | 250 | 75 | 18 |

| 315 | 315 | 60 | 29.1 |

| 400 | 355 | 60 | 52.9 |

| 500 | 400 | 45 | 69.8 |

| 630 | 450 | 45 | 125 |

| 800 | 500 | 35 | 174 |

| 1000 | 560 | 30 | 261 |

| 1250 | 630 | 20 | 305 |

What is the difference between an auger and a conveyor?

Here's a table summarizing the key differences:

| Feature | Auger | Conveyor |

| Mechanism | Rotating screw | Moving belt or chain |

| Movement | Primarily vertical/steep | Primarily horizontal |

| Material Handling | Granular, powdery | Wide range, including bulk solids, packages, liquids |

| Advantages | Compact, versatile for vertical transport, handles sticky materials | Gentle handling, long-distance transport, high capacity |

| Disadvantages | Prone to material damage, limited horizontal reach | Complex installation/maintenance, less suitable for steep inclines |

special design

We produce different types of auger feeder for selection, including (tube type, U type) (single shaft, shaftless), material: carbon steel, stainless steel. Reasonable selection and design can be carried out according to the particle size, conveying volume and conveying distance of the conveyed material, so as to avoid material jamming, arching and smooth discharge. Parameters and drawings are provided free of charge.

In addition to the above parameters and structures, we can also customize according to your requirements, such as: the machine needs 304 stainless steel, a universal wheel, or a discharge port at the bottom, or an anti-blocking switch, or other special designs, etc. Please contact us.

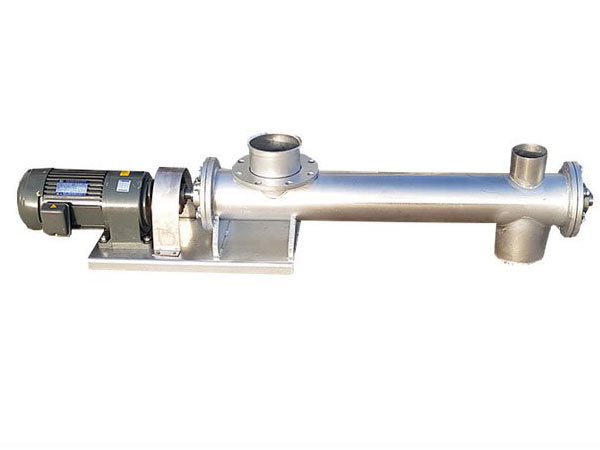

Structure

Auger Screw: A helical screw that rotates to move materials along its length.

Hopper: A container that holds the bulk material before it enters the auger.

Drive Motor: Powers the rotation of the auger.

Discharge Outlet: The point where the material exits the auger feeder.

Design options

Silo (large/small, round, square, irregular)

Multiple inlets/outlets

U-pipe

special motor

Add moving wheel

Special material (metal or non-metal)

not fixed adjustable height

Data outside the parameter table

Supporting program

Auger feeder is often used in conjunction with other equipment during the production process to achieve automated and efficient material handling.

1. With vibrating screen: Auger feeder continuously and evenly feeds materials into the vibrating screen, and the vibrating screen screens out materials of different particle sizes through the screen.

2. With mixer: Auger feeder continuously feeds multiple materials into the mixer in proportion, and the mixer mixes the materials evenly through mechanical stirring or air flow mixing.

3. With packaging machine: Auger feeder continuously and evenly feeds materials into the packaging machine, and the packaging machine automatically completes packaging processes such as metering, filling, and sealing.

4. With dust-free feeding system: Auger feeder continuously feeds materials into the dust-free feeding system, and the dust-free feeding system sucks the materials into a closed container through negative pressure to avoid dust flying.

Application section

Building materials industry: used to transport granular materials such as cement, lime, sand, etc. from storage to concrete mixing plants.

Chemical industry: used to transport chemical raw material powders, such as pigments, plastic particles, alumina, etc. to reactors or mixing equipment.

Food processing industry: used to transport food raw materials such as flour, powdered sugar, and grains to food processing equipment for mixing or processing.

Agricultural field: used to transport agricultural granular materials, such as feed, seeds, etc., to different processing or storage equipment. During the grain harvesting process, it is used to transport harvested crop particles to storage equipment or transport vehicles.

Environmental engineering: used to transport solid waste or waste to disposal facilities such as incinerators and landfills.

Mining industry: used to transport granular materials such as ore, coal, slag, etc. to provide them to mining equipment or processing equipment.

Solutions by Industry

-

For flour mill

The company uses a screw feeder to transport wheat flour from the storage silo to the mixing equipment, which improves production efficiency, ensures uniform feeding, reduces manual intervention, and reduces dust pollution.

-

For plastic processing plant

Auger feeder is used to transport recycled plastic particles to the extruder, achieving continuous feeding, improving the automation level of the production line and reducing material waste.

-

For cement plant

In the cement production process, auger feede is used to transport cement powder from the storage silo to the packaging equipment, which improves the stability and accuracy of feeding, optimizes the production process and reduces energy consumption.