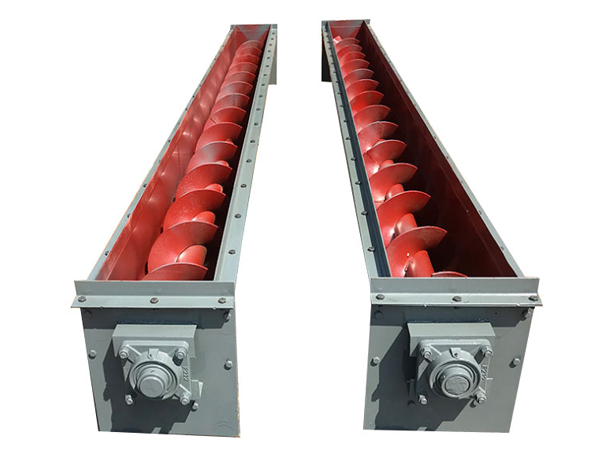

Auger Screw

A mechanical device that utilizes a rotating helical screw blade, often referred to as "flighting," to transport various materials within a tube or trough.

Auger diameter: 100mm-600mm

Length: 2-20m

Conveying angle: 0-90°

Material: Carbon steel, stainless steel, plastic

Application: Used to move materials such as grains, powders and granular matter from one point to another.

Introduction of Auger Screw

Auger screw, also known as auger screw conveyor, consists of a spiral blade (auger) rotating inside a cylindrical tube. As the screw turns, it moves the material along the length of the conveyor, usually used horizontally or slightly inclined, but can also be arranged vertically in special cases, suitable for conveying powders, granules, sheets or viscous materials, including food waste, wood chips, aggregates, grains, animal feed, boiler ash, meat, bone meal, municipal solid waste, etc.

Auger screws can be customized to meet specific application requirements including material, length, diameter and screw design.

Types of Auger Screw

Here are some common types of auger screws:

Shafted auger screw: includes a central shaft, with spiral blades wrapped around the shaft to form a spiral structure. It is often used to transport materials horizontally or obliquely, and is suitable for a wide range of industrial fields, such as food processing, chemical industry and agriculture.

Shaftless auger screw: has no central shaft, suitable for conveying sticky or easily adhered materials, and is often used to handle the transportation of sticky materials such as waste, mud and sludge.

Tubular auger screw: There is a tube wall around the spiral blade to form a closed conveying channel, which is suitable for occasions where it is necessary to prevent material spillage or environmental pollution, such as the transportation of powder and granular materials.

U-shaped auger screw: The conveying trough is U-shaped, which can effectively prevent material spillage. It is often used for the transportation of cement and granular materials, and is suitable for limited space or occasions where it is necessary to prevent material accumulation.

Auger Screw Working Principle

1. Feeding: The material is placed at the feed port, usually a hopper or storage box, and the material enters the screw conveyor through gravity or other mechanical equipment (such as an elevator).

2. Screw rotation: The motor drives the screw shaft to rotate, and as the screw rotates, the material is pushed along the direction of the screw.

3. Conveying process: The material moves evenly along the length of the conveyor under the push of the screw.

4. Discharging: When the material reaches the discharge end of the conveyor, it is released through the discharge port.

Features and Benefits

Strong adaptability: The shape, pitch, cross-section and other parameters of the spiral blade can be optimized according to the material characteristics to adapt to materials of different particle sizes, densities and viscosities.

Accurate conveying: By adjusting the parameters of the spiral blade, accurate flow control can be achieved to meet the needs of different production processes.

Continuous conveying: The continuous rotation of the screw drives the material forward to achieve continuous and stable conveying.

Closed conveying: Auger screw usually adopts a closed structure, which can effectively prevent material leakage and dust flying, and is suitable for the conveying of hygienic or toxic and harmful materials.

Video

Technical parameters

The various types of auger conveyors produced by Dahan Company are available. If you have special needs, we will design them free of charge according to your actual situation.

| Model | LS114 | LS133 | LS159 | LS219 | LS245 | LS273 | LS315 | LS400 | LS500 | LS600 |

|

Diameter (mm) |

114 | 133 | 159 | 219 | 245 | 273 | 315 | 400 | 500 | 600 |

|

Rated speed (r/min) |

84- 130 | 84-130 | 84-130 | 84-130 | 84-130 | 84-130 | 84-130 | 62-100 | 62-100 | 62-100 |

|

Reference capacity (m³/h) |

1 | 1.3 | 5 | 15 | 20 | 30 | 40 | 45 | 70 | 100 |

|

Motor power (Kw) |

2.2-18.5 | |||||||||

|

Admission biggest gradient (o) |

<60 | |||||||||

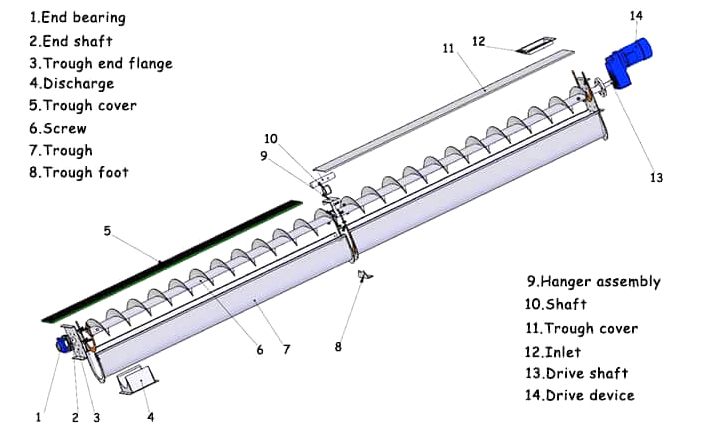

Structure of Auger Screw

Auger screw is mainly composed of driving device, head assembly, shaft-less screw, groove liner, inlet, outlet, cover (when needed), base, etc.

1- The driving device adopts helical gear reducer. The reducer is opposite to the outlet when horizontal and the reducer is at the outlet when inclined.

2- The cabinet is U, and the upper part is covered with rain proof machine cover. The material is stainless steel or carbon steel.

3- Non - axial spirals: stainless steel or 16Mn.

4- Trough lining: nylon or polyethylene plate, nylon material.

5- There are two kinds of inlet and outlet: the square and the round. The form of general inlet and outlet is decided by the user and the square is the main one.

Custom Engineered

Auger screw can be customized in many different types according to different design and application requirements. Here are some common customized types of auger screw:

Water-cooled auger screw: A screw conveyor used for high-temperature material transportation. The screw mechanism is usually cooled by a water cooling system during the transportation process to ensure that the equipment and materials are not affected by overheating.

Double-shaft auger screw: A conveyor with two screw shafts, suitable for occasions requiring higher conveying capacity or two-way conveying, and the material can also be stirred during the conveying process.

Adjustable slope auger screw: The design of the conveyor slope can be adjusted as needed to adapt to the conveying of materials at different heights or angles.

Anti-corrosion auger screw: Made of corrosion-resistant materials, it is suitable for conveying corrosive materials such as chicken manure, pig manure, cow manure, chemical powder, etc.

Options

Full-face spiral blade: The blade completely covers the spiral shaft, which is suitable for conveying loose materials.

Multi-head belt spiral blade: The blade is composed of multiple belt-shaped blades, which is suitable for conveying sticky materials or materials that are easy to agglomerate.

Paddle spiral blade: The blade is paddle-shaped, which is suitable for conveying granular materials and can convey and mix materials.

Standard pitch sawtooth angle single-head spiral: Suitable for conveying materials with high wear resistance requirements.

Application

Grain processing industry: used for conveying and processing grains, grains, feed, etc., such as grain storage, grinding systems, granular material conveying, etc.

Chemical industry: used for conveying chemical raw materials, powders, granular materials, such as fertilizer production, plastic processing, pigment production, etc.

Building materials industry: used for conveying construction materials such as cement, sand, stone, such as concrete mixing stations, sand and gravel yards, etc.

Environmental protection industry: used for solid waste treatment, wastewater treatment, such as garbage treatment plants, wastewater treatment equipment, etc.

Food processing industry: used for conveying and processing food raw materials, such as flour production lines, candy production lines, etc.

Metallurgical industry: used for conveying and processing of minerals such as iron ore and coal ore, such as iron smelting plants, steel mills, etc.

Pharmaceutical industry: used for conveying and processing of pharmaceutical raw materials, such as pharmaceutical production lines, drug batching systems, etc.

Papermaking industry: used for conveying and processing of pulp, paper, etc., such as papermaking production lines, paper processing equipment, etc.

Solutions by Industry

-

Customer Name: Urban Waste Treatment Center

Case Overview: The waste treatment center uses a screw conveyor to transport and process domestic waste.

Solution: Custom-designed wear-resistant spiral blades and sealing design ensure effective transportation and prevent odor leakage, reducing secondary pollution.

-

Customer Name: Farm Feed Processing Plant

Case Overview: The feed processing plant uses a screw conveyor to transport and mix feed raw materials.

Solution: Food-grade coated spiral blades ensure feed hygiene and safety; adjustable blade design to meet different feed mixing ratio requirements.

-

Client Name: Plastics Manufacturing Company

Case Overview: The plastics manufacturing company uses screw conveyors to transport and process plastic particles.

Solution: Spiral blades treated with wear-resistant coatings, anti-static design to avoid particle adhesion; high-speed design to improve the conveying capacity and stability of the production line.