Carbon Steel Screw Conveyor

Made of mild steel material, the material is easily and continuously conveyed by the rotating helical blade, which is suitable for applications where cleanliness and corrosion are not strictly required, and the cost is low.

Material: Q235 carbon steel

Conveying length: 2-70 meters

Conveying capacity: 142 cubic meters per hour

Conveying angle: 0-90 degrees

Introduction of Carbon Steel Screw Conveyor

The carbon steel screw conveyor is made of carbon steel, and the machine is painted to reduce the wear of the material on the machine and slow down the rusting speed of the machine itself. It has the characteristics of low purchase cost, large conveying capacity, and small machine specification restrictions. Certain corrosion resistance can realize normal material transportation.

Carbon steel screw conveyor is suitable for various industries, such as building materials, chemical industry, electric power, metallurgy, coal and other industries, suitable for horizontal or inclined conveying powder, granular and small block materials, such as coal, ash, slag, cement, etc.

Types of Carbon Steel Screw Conveyor

|

|

|

|

|

| U type screw conveyor | Tubular screw conveyor | Shaftless screw conveyor | Double screw conveyor | Mobile screw conveyor |

|

|

|

|

|

| It can convey powder, granule and small pieces of material, suitable for 0-15 degree conveying | It can transport powdery and granular materials, and can transport horizontally, inclined and vertically | It is suitable for horizontal or slightly inclined conveying of viscous, easily clogged materials or ribbon-like materials that are easily entangled with extremely low water content. | It can crush and mix materials, and the conveying capacity is 1.2-5 times higher than that of a single shaft. | Can move freely according to the situation on site |

Function of Carbon Steel Screw Conveyor

Light duty models: Mainly used for conveying powder or granular materials in pet food production, the plastics industry, and the processing of soaps, laundry powders and detergents.

Medium and heavy models: mainly used in animal feed processing, wood processing, chemical industry and environmental technology for municipal and industrial applications.

Extra heavy duty models: Mainly used in cement/lime/gypsum and mining industries.

Product collocation

Advantages and Disadvantages of Carbon Steel Screw Conveyors

Advantages:

1. Ordinary carbon steel blades can get higher hardness and better wear resistance after heat treatment

2. The hardness of ordinary carbon steel in the annealed state is very moderate, and it also has good machinability

3. The raw materials of ordinary carbon steel are very common, easy to obtain, and the production cost is relatively low

Summary: The screw conveyor has wear resistance and machinability in the process of conveying materials, which can increase the service life of the screw conveyor blades, and the production cost of carbon steel screw conveyor blades is relatively low.

Disadvantages:

1. The hot hardness of ordinary carbon steel will be poor, because when the working temperature is greater than 200 degrees, its hardness and wear resistance will drop sharply.

2. The hardenability of ordinary carbon steel is very low. The diameter of the fully hardened steel is generally about 15-18 mm during water quenching, while the diameter or thickness of the unquenched steel is only about 6 meters, so it will be easier to deform and crack. .

Summary: When the conveyed material has a temperature, it is necessary to cool the material, otherwise when the temperature is greater than 200°, the spiral blade is easy to deform and crack.

Video

Technical Parameters

| LS Type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX Type | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter(mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| pitch(mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Rotating speed(r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Delivery volume QΦ=0.33(m3/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| power Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| power Pd 1=30m(KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Rotating speed(r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Delivery volume QΦ=0.33(m3/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| power Pd 1=10m(KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| power Pd 1=30m(KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Rotating speed(r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Delivery volume QΦ=0.33(m3/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| power Pd 1=10m(KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| power Pd 1=30m(KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Rotating speed(r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Delivery volume QΦ=0.33(m3/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| power Pd 1=10m(KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| power Pd 1=30m(KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

The various types of carbon steel screw conveyors produced by Dahan Company are available. If you have special needs, we will design them free of charge according to your actual situation.

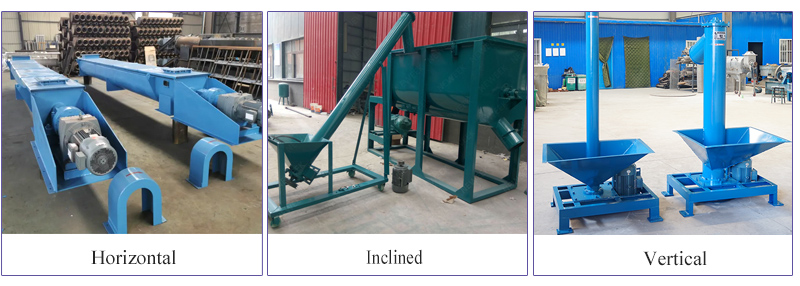

Optional Equipment

1. Horizontal carbon steel screw conveyor: It is convenient for multi-point loading and unloading, and the mixing, stirring or cooling functions can be completed at the same time during the conveying process. It is suitable for continuous and uniform conveying of loose materials horizontally or slightly inclined (below 20°), and the conveying distance is generally not more than 70 meters.

2. Inclined carbon steel screw conveyor: use the motor to drive the screw to rotate through the reducer, and through the rotation, the material is moved along the fixed casing to carry out the conveying work, so as to convey the material to the predetermined position, the inclination angle is 0-60°, and the conveying work is carried out. The length can reach 20 meters, and the conveying capacity can reach 100 cubic meters per hour.

3. Vertical carbon steel screw conveyor: the speed of the screw body is higher than that of the ordinary screw feeder. Under the action of centrifugal force, the added material generates friction with the casing, which prevents the material from rotating with the screw blades and It overcomes the gravity of the falling material, so as to realize the vertical conveying of the material. The lifting height is generally not more than 8 meters.

Application

Carbon steel screw conveyors are mainly used to convey materials that do not require high hygiene or corrosion resistance. They are suitable for various industries, such as building materials, chemical industry, electric power, metallurgy, coal and other industries. They are suitable for horizontal or inclined conveying powder. , granular and small block materials, such as coal, ash, slag, cement, etc.

Solutions by Industry

1. Carbon steel screw conveyor is used for garbage disposal

When the carbon steel screw conveyor handles domestic or industrial waste, it usually chooses a shaftless design to avoid more ribbon-shaped materials in the waste winding around the screw shaft, causing blockage, affecting the conveying efficiency, and even causing the screw shaft to break

2. Carbon steel screw conveyor is used to treat mud sludge

The carbon steel screw conveyor here can be in the form of a shaft or without a shaft. The carbon steel screw conveyor in the shaft form can be used to deal with mud with a large water content, which can achieve a good conveying effect; if it is processed by a filter press For extremely low water content sludge, choose a shaftless carbon steel screw conveyor to avoid sludge clogging.

3. Carbon steel screw conveyor is used to process sandstone coal ash

It is sincerely recommended to choose a sealed tubular carbon steel screw conveyor. At this time, the fly ash and sand are all industrial materials, which require a large amount of transportation and are used for inclined transportation from low to high. The tubular carbon steel screw conveyor is fully sealed. The design can ensure the flow rate of inclined conveying, and block the conveying dust, and at the same time avoid rainwater infiltration to cause material agglomeration in rainy days.