chicken feed screw conveyor

Used to transport chicken feed from storage locations to feeders or other processing equipment, conveyors are usually made of stainless steel or other corrosion-resistant and easy-to-clean materials, reducing the risk of contamination and making the conveyor easy to clean.

Diameter: 100-1250mm

Angle of inclination: 0-90 degree

Hopper Size: 100L, 230L

Loading capacity: 250kg

Conveying height: ≤8 meters

Product introduction of chicken feed screw conveyor

Chicken feed screw conveyor is used for material conveying, feeding and other processing techniques in feed mills, or chicken feed processing lines, etc. The hopper feeds the feed, and the feed is sent to the discharge end of the conveyor by the screw shaft, and the discharge end sends the feed into the packaging bag or into the mixer or feeder. The part of the chicken feed screw conveyor in contact with the chicken feed is made of stainless steel, the feed is completely free from pollution during the conveying process, and the fully enclosed automation of the production process is realized.

Applications

Chicken feed screw conveyors have many applications in the poultry industry, including:

Raw Material Handling: Used to transport chicken feed from storage silos or bags to mixing or processing equipment.

Processing: Can be used to convey chicken feed to various stages of the processing system, for example from the grinding process to the mixing process. This allows for a continuous flow of chicken feed throughout the production process, helping to improve operational efficiency and productivity.

Packaging: Typically used to convey chicken feed to packaging equipment such as baggers or filling machines. This enables efficient and accurate packaging of chicken feed into bags, containers or other packaging formats.

Waste Disposal: Can be used to transport chicken feed waste, such as spillage or product that does not meet quality standards, to a waste disposal system for disposal or recycling. This helps ensure that the chicken production process is environmentally friendly and sustainable.

Feeding: Machines are used to convey chicken feed from storage silos to feeders or other processing equipment. Screw conveyors can be designed to provide an accurate and consistent feed rate, which helps ensure the chickens are getting the right amount of feed.

Video

Product number

| Model | LSY100 | LSY120 | LSY140 | LSY160 | LSY200 | LSY250 | LSY300 | LSY400 | ||

| Shell tube diameter (mm) | Φ114 | Φ133 | Φ168 | Φ194 | Φ219 | Φ273 | Φ325 | Φ402 | ||

| Angle (α) | 0°~60° | |||||||||

| Conveying capacity (m) | 8 | 10 | 12 | 14 | 15 | 18 | 20 | 25 | ||

| Conveying capacity (t/h) | 6 | 12 | 17 | 28 | 45 | 70 | 130 | 150 | ||

| Moter | Model | L≤7 | Y90S-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y132M-4 | Y160M-6 |

Y160L-4 Y180M-4 |

Y180L-4 |

| Power(KW) | 1.1 | 2.2 | 3 | 5.5 | 7.5 | 11 | 15-18.5 | 22 | ||

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160M-6 |

Y160L-4 Y180M-4 |

Y180M-4 Y180L-4 |

YH200L-4 | |

| Power(KW) | 2.2 | 3 | 4 | 7.5 | 11 | 15 | 18.5-22 | 20-30 | ||

Product advantages

1. Gentle handling: The screw conveyor is designed for gentle handling of materials, which is very important when transporting chicken feed. The slow and controlled movement of the screw conveyor helps prevent feed damage, reducing waste and improving overall feed quality.

2. Accurate and reliable: The screw conveyor is accurate and reliable, which is very important for the poultry industry where precise feed delivery is crucial. The screw design ensures that material moves at a consistent rate along the length of the conveyor, which helps increase the efficiency of the production process.3. Hygienic design: Hygienic design can be adopted to meet the strict hygiene requirements of the food industry. The smooth surfaces of the stainless steel screws and pipes reduce the risk of contamination and make the conveyor easy to clean. This helps to ensure that chicken feed is transported in a safe and hygienic manner.

4. Customizable design: Can be customized to meet the specific requirements of the application, including the size and shape of the screw and the diameter and length of the pipe. This makes it possible to tailor solutions to the needs of the production process.

5. Low maintenance cost: Compared with other types of conveying systems, screw conveyors require the least maintenance. Stainless steel components are extremely durable and require no lubrication, which helps reduce maintenance costs and downtime.

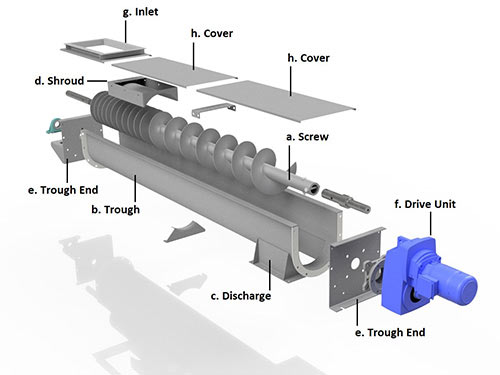

product structure

The chicken feed screw conveyor is mainly composed of a driving device, a trough, a screw shaft, a trough liner, an inlet, an outlet, a cover (if necessary), a base, etc.

Driving device: Helical gear reducer is used. When it is horizontal, the reducer is facing the exit, and when it is inclined, the reducer is at the exit.

Feed trough: The material is stainless steel or carbon steel, which can be designed as tubular or U-shaped.

Inlet and outlet: There are two kinds of square and round. Single or multiple inlet and outlet can be designed.

Spiral shaft: used to push the feed to the specified direction.

special design

Solutions by Industry

-

Poultry Feed Mill

A poultry feed mill in the Indonesia uses screw conveyors to transport chicken feed from the storage silos to the mixing equipment. The screw conveyors are designed with stainless steel screws and tubing to ensure that the chicken feed is transported in a hygienic and dust-free manner. The screw conveyors are also equipped with dust-tight seals and other features to minimize the risk of contamination.

-

Chicken Farm

A chicken farm in Philippines uses screw conveyors to transport chicken feed from the storage silos to the feeding equipment. The screw conveyors are designed with a special coating to prevent the chicken feed from sticking to the screw or tubing. The screw conveyors are also equipped with a dust collection system to minimize dust emissions and improve the safety of the production process.

-

Animal Feed Processing Plant

An animal feed processing plant in Australia uses screw conveyors to transport chicken feed through various stages of the processing system, such as from the grinding process to the mixing process. The screw conveyors are designed with a heavy-duty screw and tubing to withstand the abrasive nature of the chicken feed. The screw conveyors are also equipped with a variable frequency drive to control the speed of the screw and ensure a consistent feed rate.