Concrete Screw Conveyor

Conveying equipment commonly used in concrete mixing plants and stabilized soil mixing plants

Conveying capacity: 150t/h

Conveying angle: 0°-60°

Motor power: 1.1-30KW

Concrete screw conveyors are used for conveying or feeding cement and cement-like materials in concrete batching plants and other building material processing plants

Introduction of Concrete Screw Conveyor

Concrete screw conveyors are mainly used for conveying or feeding cement and cement-like materials in concrete batching plants and other building material processing plants. It is a conveying machine that uses a rotating continuous spiral blade belt to push materials in a closed tube.

The feeding port adopts spherical feeding port, which is rotatable and easy to disassemble. The shell is connected by steel pipes through flanges to form a whole, with good overall rigidity, good sealing performance, no water seepage and material leakage, and can be directly matched with it. Equipment connection is fixed.

Features and Benefits

1. It adopts the heavy-duty design of the reducer, which has the characteristics of large torque and low noise.

2. Concrete screw conveyor is a high-precision continuous seamless spiral blade after cold hardening, the outer edge hardness reaches HB240, the pitch error is small, and the dynamic balance accuracy is high.

3. There are various interface connection methods such as spherical hinge, nozzle, flange and square flange for the inlet and outlet.

4. There is an anti-seepage device at the connection of the shell pipe, which can avoid the cement agglomeration caused by the infiltration of rainwater outdoors, which will cause material blocking and boring events.

5. Each transmission part adopts floating connection, so that the spiral body, the hanging bearing and the tail form a suspended body, and no material is stuck or blocked.

6. The suspended intermediate hanging bearing frame increases the material transportation space and reduces the logistics resistance. Coupled with the design of small diameter, high speed and variable pitch, it ensures smooth, fast and even feeding.

7. It can realize the conveying, lifting and loading and unloading of materials, and at the same time carry out operations such as mixing, stirring, heating and cooling.

Video

Technical Parameters

The concrete screw conveyor produced by Dahan Company are available in various models, and we can also customize them according to your needs.

Product number

| Model | Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

Selection skills of concrete screw conveyor

1. Conveying capacity: Conveying capacity demand determines the pipe diameter and motor power of the conveyor. According to different conveying capacity demand, the required screw conveyor model can be roughly estimated;

2, transmission Angle: in theory, concrete screw conveyor can achieve 0-60° inclined transmission, but in 45° above the transmission capacity will have a more obvious weakening, the need to adjust the motor power and spiral speed to ensure the transmission capacity, the specific situation needs to be calculated;

3, transmission distance: from the motor to the other end, the motor pulling ability of the helical stranding dragon will gradually weaken, the longer the transmission distance, the larger the diameter of the pipe, the weaker the force is more obvious, so the moderate transmission distance and matching motor power, can also ensure good concrete transmission efficiency;

4. Feed flow: Concrete screw conveyor feed flow size is another factor to ensure the throughput and machine life, too little feed easy to lead to spiral idling, too little feed easy to cause timely delivery and blockage, will greatly reduce the service life of concrete screw conveyor, so in the selection of the model, to consider the feed flow or adjust the feed flow after selection;

5. Connection form: depending on the frequency of disassembly, choose universal ball (relatively fixed) connection or bag soft connection (frequent disassembly).

In addition, the material of concrete screw conveyor is generally Q235 carbon steel, if you have special needs you can also customize the material, color or other aspects.

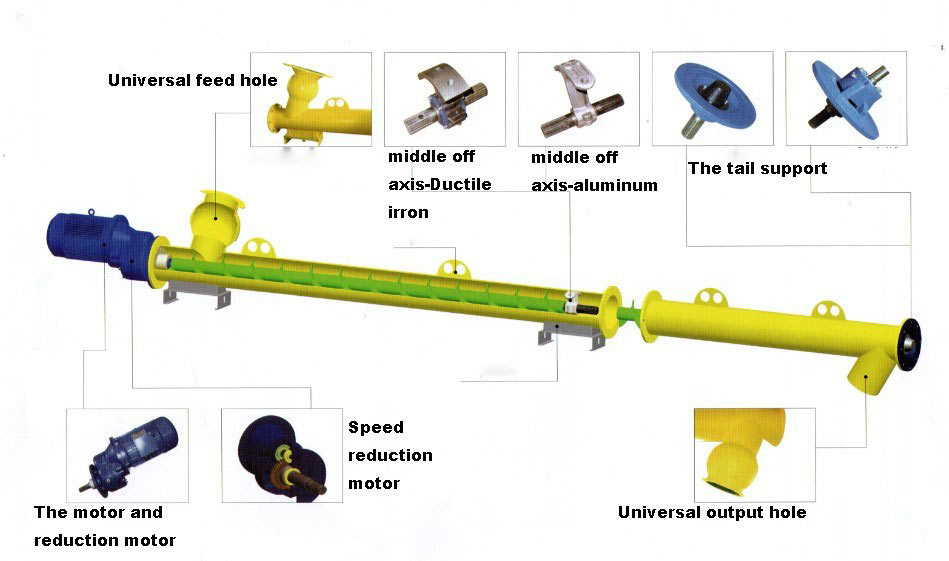

product structure

Concrete Screw Conveyor is mainly composed of inlet and outlet, pipe body, screw blade, reducer and driver.

Inlet and outlet: The feed port is no longer fixed, and a universal ball is used to connect above the feed port, so that the direction of the feed port can be adjusted at will, which is flexible and convenient, and is more closely connected with the feeding equipment.

Pipe body: a container mainly used to load concrete, which can be tubular or U-shaped.

Spiral blade: The main force that pushes the concrete forward. The material and thickness of the spiral blade can be replaced and adjusted.

Reducer and driver: provide power for concrete conveying, and at the same time limit the screw rotation speed through the reducer to ensure conveying efficiency and production safety.

Application

Concrete Screw Conveyor is usually used in large cement plants, mixing stations and some concrete batching plants. Dry cement can be conveyed by ordinary screw conveyors. Wet cement is highly viscous and easy to agglomerate, so Concrete Screw Conveyor is required for conveying. It can also transport common chemical materials such as fly ash.

Solutions by Industry

-

concrete conveying site for auger conveyor

Conveying material:Concrete

Recommended equipment: Screw conveyor