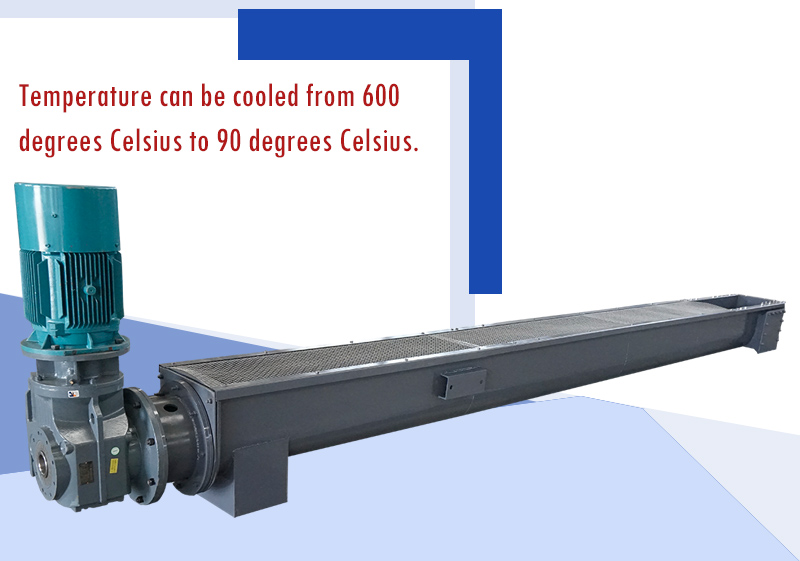

Cooling Screw Conveyor

Using a hollow helical structure, cooling water in the jacket can cool the temperature of the material from 600 degrees Celsius to 90 degrees Celsius.<

Material temperature: Input: 600°C Output: 90°C

Conveying distance: 20 meters

Cooling screw conveyors can meet the feeding and discharging requirements of reclaimed sand in foundries, coal-fired power plants or drying plants, and are generally suitable for bed ash, flue dust, sewage slurry, cyanide or pasture under various conditions.

Introduction of Cooling Screw Conveyor

Cooling screw conveyor is to transport high-temperature powder, small granular and other bulk materials in a closed pipe body. The maximum temperature of the feeding material can reach 600 ℃. The cooling water flowing in the spacer and the central spiral pipe makes the discharge temperature reach 90 ℃. It is a conveying equipment that integrates cooling and conveying.

Cooling screw conveyor includes a feeding unit, a discharging unit, a cylinder, a cooling unit, a driving unit and a supporting unit. The feeding unit and the discharging unit are respectively arranged at both ends of the cylinder, and the driving unit makes the cylinder surround its central axis of symmetry. Rotate, the support unit supports the cylinder, the cylinder includes an outer cylinder and an inner cylinder, a jacket with a fixed length is arranged near the outer circumference of the outer cylinder of the feeding unit, and the cooling unit includes a set of a central part of the discharging unit. The water inlet pipe, the hollow helical blade arranged in the inner cylinder and communicated with the water inlet pipe, the water outlet pipe arranged in the central part of the feeding unit and communicated with the hollow helical blade, and the fixed length jacket The hollow baffle or hollow helical blade is connected with the cooling water, so that the material can be cooled during the conveying process to achieve the cooling effect.

Function of Cooling Screw Conveyor

In addition to conveying materials, the cooling screw conveyor can also cool high-temperature materials. The machine is equipped with a cooling system inside and outside the machine, and the outer cylinder of circulating water is used to keep the water at a low temperature and reduce the heating degree of the machine. Can meet the individual needs of users. It is used to transport materials with high temperature above 600°C cooled to a temperature compatible with downstream processes (usually less than 200°C).

Cooling principle of cooling screw conveyor

The cooling screw conveyor adopts the principle of hollow screw and heat exchanger. The hollow design provides space and path for the cooling medium to flow through. At the same time, during the conveying process, the screw blades and the screw shaft are continuously rotated and are in constant contact with the material being conveyed. The hollow helical surface acts as a solid partition to separate the cooling medium from the material and form heat exchange. This means that not only the conveyed material can be cooled, but it can also be kept warm or even heated as required.

Features and Benefits

1. The temperature can be cooled from 600 degrees Celsius to 90 degrees Celsius.

2. The conveying length of a single screw can reach up to 20 meters, and it can be used in connection with multiple devices, and can directly cooperate with the feeding system for automatic work.

3. Sealed conveying is conducive to conveying materials that are easy to fly, hot and smelly, which can reduce environmental pollution and improve the working conditions of workers.

4. It can be conveyed in the reverse direction, and one conveyor can also convey materials in two directions at the same time, that is, to the center or away from the center.

5. The weight of the spiral blade is large, the pressure in the pipe groove is large, the material is easily crushed during the conveying process, and the wear rate of the spiral structure will be higher than that of the ordinary spiral, so do not convey fragile high-value materials.

Structure of Cooling Screw Conveyor

It is mainly composed of driving device, transmission device, bracket, screw conveyor shell, screw shaft, screw blade, water cooling jacket, etc.

The equipment is driven by a motor reducer, and the rotating screw shaft and screw blades push the material to move from the inlet to the outlet to complete the conveying of the material.

1. The screw shaft is made of high temperature and wear-resistant materials, and the split screw blades are used, which can be replaced separately when in use.

2. The water-cooled shaft is a hollow structure made of high-quality steel, which serves as the bearing shaft of the screw body and transmits torque.

3. The water-cooled tube is used for circulating cooling of the water-cooled shaft, which improves the working environment of the shaft and prolongs the service life of the shaft.

When the equipment is in use, the cooling water enters one end of the water-cooling tube through the rotary joint, flows into the water-cooling shaft through the water-cooling tube, and the cooling water is discharged through the rotary joint. The rotary joint realizes circulation cooling through the water-cooled shaft.

Working system: S1 (continuous working system)

Pressure: 0.6MP (working pressure of cooling water);

Cooling temperature: feed temperature 720 degrees Celsius, discharge temperature below 150 degrees Celsius

Cooling water velocity: 0.37m/s

Cooling water volume: 4.285t/h (the cooling water temperature is 20 degrees Celsius before cooling, and the amount of water required for 100 degrees Celsius after cooling).

Technical Parameters

| Spiral diameter(mm) | 300 | 400 | 500 |

| Pitch(mm) | 300 | 400 | 500 |

| Rotating speed(r/min) | 6 | 7 | 8 |

| Delivery volume(m3/h) | 3 | 5 | 10 |

| Motor Power(Kw) | 3 | 3-4 | 4 |

| Conveying distance(m) | <7 | <7 | <7 |

| Material temperature(℃) | <800 | <800 | <800 |

| Material specific gravity(%) | ≈0.8 | ≈0.8 | ≈0.8 |

| Blade material | SU304 | SU304 | SU304 |

| Water pressure(MPa) | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 |

| Import and export | DN40 | DN40-50 | DN40-50 |

The various types of cooling screw conveyors produced by Dahan Company are available. If you have special needs, we will design them free of charge according to your actual situation.

video

Application

During the processing of many bulk materials, it is necessary to cool, heat or maintain a specific product temperature while conveying the product. The required temperature fluctuations must be calculated and designed into the system to achieve the preferred goals, the cooling screw conveyor is the perfect solution for these applications:

Common applications: cooling fly ash from coal fired power plant boilers, heating lime for asphalt shingle operations, maintaining a specific temperature for food products, cooling drill cuttings from rotary dryers, cyanide

Application scenarios: coal-fired power plants, boiler rooms, foundries, ranches, food processing plants

Overall, cooling screw conveyor is used in various industries that require temperature control during material conveying. Some examples include:

1. Plastic manufacturing: It can be used to transport plastic granules or other materials that are easy to melt at high temperatures. By adjusting the temperature of the material during transportation, it can help prevent degradation or other problems that may affect the quality of the final product.

2. Chemical processing: It is often used in chemical processing applications that generate heat due to chemical reactions during the transportation of materials. By removing heat from the material, it can help prevent problems like caking or caking and maintain the quality of the final product.

3. Food production: It can be used in food production applications, conveying chocolate or other confectionary items that require temperature control during the conveying process. By adjusting the temperature of the material, it can help prevent melting or other problems that may affect the quality of the final product.

4. Thermal power plant: It can be used for high-temperature fly ash produced during the combustion of coal or other fuels in thermal power plants. Water cooling helps prevent fly ash from overheating and causing problems like clogging or equipment failure.

5. Garbage incineration power generation facilities: transport the high-temperature fly ash produced in the process of garbage incineration. Water cooling helps regulate the temperature of the fly ash, preventing it from melting or causing other problems during transport.

6. Fly ash collection system: Coal-fired power plants produce a large amount of fly ash. This fly ash can be conveyed to a collection system for further processing or disposal using a water-cooled screw conveyor.

7. Iron and steel production: Fly ash will be produced in the process of iron and steel production, which can be transported by water-cooled screw conveyor for further processing or disposal. Water cooling can help prevent fly ash from overheating and agglomeration during transportation.

Precautions for use

1. Material cooling range: According to the design of the temperature difference between the highest temperature and the lowest temperature of your material, the length of single-stage cooling generally does not exceed 7 meters.

2. Cold source temperature: The initial temperature of the cold source temperature of 5°C and 30°C has different effects on the design of the same equipment, so it is necessary to prepare the necessary information before the design plan in order to design a reasonable water cooling plan for you.

3. Material properties: Different materials have different heat dissipation properties. Before ordering equipment, accurate information must be provided so that our company can perform calculus simulation to ensure the cooling effect.

4. The location of equipment installation space: it is beneficial to the application of low-temperature cooling, and a larger area is required for occasions with a large cooling range. The arrangement can be arranged horizontally, vertically, or diagonally.

5. On-site power supply: In the design of water-cooled cooling, the ultra-high temperature cooling system is not limited to the form and structure of water-cooled cooling. The design plan will also design composite process structures such as air cooling.