fly ash screw conveyor

It is used in stone processing plants or concrete conveying plants to convey fly ash into mixing stations, silos or for proportioning. It is completely sealed and has a large conveying capacity.

Spiral diameter: 140-290mm

Conveying length:30-60 meters

Delivery capacity: 1.4-458 cubic meters per hour

Delivery angle:0-60°

Motor power: 2.2-30KW

Speed: 240-310r/min

Product introduction of fly ash screw conveyor

Fly ash screw conveyor provides efficient, reliable and flexible material transport solutions for fly ash handling and processing in power plants, cement plants, waste management facilities and other industries that generate fly ash, primarily for moving fly ash from Collection hoppers or silos for transportation to storage facilities or processing equipment.

Typically used in power plants, cement plants and other industries that generate fly ash by-products. They facilitate the efficient and reliable movement of fly ash, facilitating its storage, disposal or utilization in various applications, such as cement production, construction materials or waste encapsulation. The specific design and configuration of the fly ash screw conveyor may vary depending on factors such as material properties, conveying capacity, distance and process.

Application

Screw conveyors play a vital role in the handling and transportation of fly ash in a variety of applications. Below are some common applications of screw conveyors in fly ash handling:

Fly Ash Collection and Storage: Used to transport fly ash from collection hoppers or electrostatic precipitators to storage bins or bins. Screw conveyors efficiently transfer fly ash from the collection point to the storage facility, ensuring a continuous and controlled flow.

Fly ash discharge from silos: Fly ash is extracted from storage silos or silos using screw conveyors and transferred for further processing or utilization. Screw conveyors help control fly ash emissions, prevent clogging and ensure a steady flow of material.

Fly Ash Conditioning: Can be used for fly ash conditioning process. For example, in the production of lightweight aggregates, fly ash may need to be conditioned with moisture. Screw conveyors with special features such as nozzles or steam injection can be used to add moisture and condition the fly ash before further processing.

Fly Ash Blending: Typically used for fly ash blending or blending applications. They can be used to combine fly ash with other materials such as cement, lime or aggregates to produce blended products for specific applications such as concrete production or soil stabilization.

Fly Ash Transport to Processing Equipment: Used to transport fly ash from storage facilities to processing equipment such as pneumatic conveying systems, mixers or reactors. Screw conveyors efficiently transport the fly ash to designated processing facilities, ensuring a continuous and controlled supply.

Fly ash disposal or recycling: Fly ash can be transported from a storage facility to a disposal area, such as a landfill or ash pond. Alternatively, screw conveyors can transport fly ash to a recycling facility where it is processed for beneficial reuse, such as in the production of building materials or as an ingredient in cement products.

Video

Advantage

1. The overall torque of the fly ash screw conveyor is greater and it adopts a variable pitch design. The pitch of the lower half is smaller than that of the upper half, commonly known as "eat less, spit faster", which can effectively prevent material clogging.

2. The surface of the continuous spiral blade is cold-rolled and hardened by cold work. The hardness and wear resistance are about twice that of ordinary blades, and the hardness of the outer edge can reach HB240.

3. There is an anti-seepage device at the joint of the shell, which can prevent the rainwater from infiltrating and causing fly ash to agglomerate and cause material blocking.

4. Suspension-type suspension bearing frame, the space for material transportation is increased, and the resistance of transportation is reduced.

5. The connection between the feed port of the screw conveyor and the cement bin is divided into two types: the rigid connection of the ball joint flange and the soft connection of hanging and waterproof canvas. The interface form depends on the frequency of disassembly and assembly of the visual equipment.

The advantages of both connection methods are that they can be adjusted in a more subtle and variable direction, and can be more closely adapted and connected to the infeed and outfeed devices.

6. Use the heavy equipment of the reducer, which has the characteristics of large torque, stronger conveying force and low noise.

Model parameters

| Model | LSY100 | LSY120 | LSY140 | LSY160 | LSY200 | LSY250 | LSY300 | LSY400 | ||

| Shell tube diameter (mm) | Φ114 | Φ133 | Φ168 | Φ194 | Φ219 | Φ273 | Φ325 | Φ402 | ||

| Angle (α) | 0°~60° | |||||||||

| Conveying capacity (m) | 8 | 10 | 12 | 14 | 15 | 18 | 20 | 25 | ||

| Conveying capacity (t/h) | 6 | 12 | 17 | 28 | 45 | 70 | 130 | 150 | ||

| Moter | Model | L≤7 | Y90S-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y132M-4 | Y160M-6 |

Y160L-4 Y180M-4 |

Y180L-4 |

| Power(KW) | 1.1 | 2.2 | 3 | 5.5 | 7.5 | 11 | 15-18.5 | 22 | ||

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160M-6 |

Y160L-4 Y180M-4 |

Y180M-4 Y180L-4 |

YH200L-4 | |

| Power(KW) | 2.2 | 3 | 4 | 7.5 | 11 | 15 | 18.5-22 | 20-30 | ||

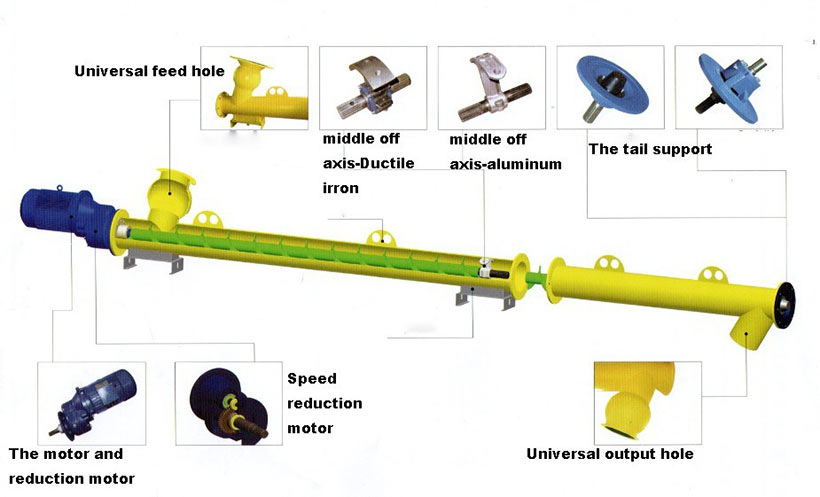

product structure

The fly ash screw conveyor is mainly composed of inlet and outlet, pipe body, screw blade, reducer, driver and connecting device.

Inlet and outlet and connecting device: The inlet is no longer fixed, and a universal ball is used for connection above the inlet, so that the direction of the inlet can be adjusted at will, which is flexible and convenient, and is more closely connected with the feeding equipment.

Pipe body: a container mainly used to load concrete, which can be tubular or U-shaped.

Spiral blade: The main force that pushes the concrete forward. The material and thickness of the spiral blade can be replaced and adjusted.

Reducer and driver: provide power for concrete conveying, and at the same time limit the screw rotation speed through the reducer to ensure conveying efficiency and production safety.

Solutions by Industry

Here are three different customer cases that demonstrate the application of fly ash screw conveyors:

-

Client: Power Plant

Application: Transport of fly ash to storage silos

Description: Power plants produce large amounts of fly ash as a by-product of coal combustion. They needed a reliable and efficient solution for transporting fly ash from collection hoppers to storage silos for further processing. Designed and installed a custom fly ash screw conveying system using abrasive materials and dust control measures. The screw conveyor efficiently transfers the fly ash from the collection hopper, ensuring its continuous flow to the storage silo. The system increases efficiency, reduces manual handling, and minimizes dust emissions, meeting the plant's environmental and operational requirements.

-

Client: Cement Plant

Application: Fly Ash Blending and Transportation

Description: Cement plants attempt to optimize fly ash utilization by mixing it with other materials to produce cement products. They needed a solution to transport fly ash from storage silos to blending equipment. A custom fly ash screw conveyor system was designed incorporating features such as variable speed control and an easy-clean design to accommodate different mix ratios and material changes. Screw conveyors efficiently transport the fly ash to the mixing equipment, ensuring precise proportions and a consistent product. The system increases production flexibility and reduces material waste, helping to increase the operational efficiency of the cement plant.

-

Client: Property Management Facility

Application: Fly Ash Treatment and Landfill

Description: Waste management facilities receive fly ash as part of waste treatment operations. They needed a solution to transport fly ash from storage facilities to landfill for final disposal. A robust fly ash screw conveyor system is employed, featuring heavy-duty construction and specialized seals to prevent material leakage. Screw conveyors efficiently transport fly ash to designated disposal areas, providing a controlled and enclosed transfer process. The system enhances the operational workflow of waste management facilities, ensuring proper disposal and compliance with environmental regulations.