Hopper Screw Conveyor

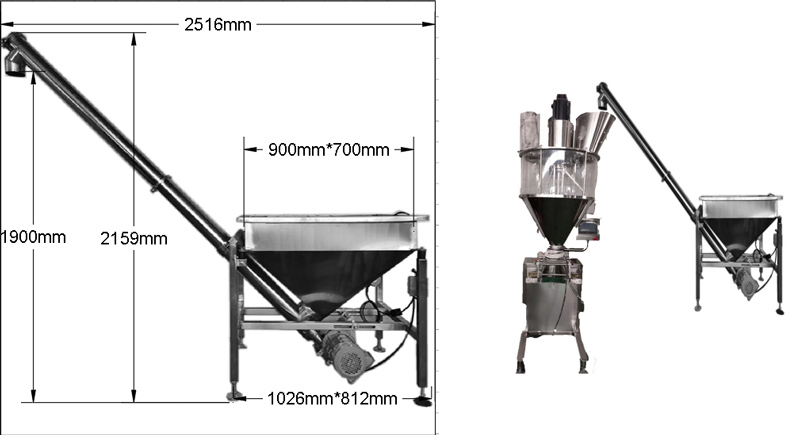

Inclined screw conveyor with hopper is used to transport bulk materials stored in the hopper, and can transport powder and granular products from the storage hopper to processing or packaging equipment. It can be connected with mixer, packing machine and vibrating screen.

Hopper size: 100L, 230L

Feed rate: 244m³/h

Loading capacity: 250kg

Feed capacity: 1000kg/h

Conveying height: ≤8 meters

Power supply: 380V/220V 50-60Hz Power: 1.5-5.5KW

-

Introduction of Hopper Screw Conveyor

Hopper screw conveyor is a screw conveyor designed to transport materials stored in a hopper, a container used to store bulk materials, the hopper screw conveyor is located below the hopper, and the material enters the screw through the feed port at the bottom of the hopper conveyor. Once the material enters the screw conveyor, the rotating screw will move along the length of the conveyor, being compacted and compressed by the screw as the material travels along the screw conveyor. This helps prevent inflation of the material and ensures its efficient transport. At the end of the conveyor, the material is discharged through an outlet at the end of the screw. Outlets can be designed to meet the specific needs of specific applications, such as chutes or discharge ports.

Hopper screw conveyors are commonly used in the food industry to convey materials such as flour, sugar and other ingredients. They are also used in other industries including agriculture, mining and wastewater treatment. Hopper screw conveyors can be customized to meet the specific needs of specific applications, making them a flexible choice for material handling.

Features and Benefits

1. The feeding pipe diameter is small, the hopper volume is 100-300KG, the conveying capacity per hour can reach 100-3000KG, and the feeding height can reach 2-12 meters.

2. The material in contact with the material is made of stainless steel. All welding ports are polished to achieve smoothness without residual material, which is clean and hygienic, and can avoid cross-contamination of materials.

3. The screw feeder uses the rotation of the eccentric block fixed on the main shaft of the motor to make the material box vibrate, and the material is easy to form flow and convection, so that it can achieve no jamming, no arching, and smooth discharge, which is suitable for poor fluidity. good material.

4. The screw can be reversed for discharging, and the lower end of the material pipe is provided with a gate, which can be opened to take out the stored material at the bottom of the hopper pipe from the door.

5. There is a material clearing port at the bottom, which can effectively prevent debris from entering the machine and cause blockage. An anti-blocking valve is set on the discharge end cover. If the material is blocked, the anti-blocking door will be opened due to the material accumulation, and then Cut off the power through the switch.

6. Sensors can be installed to effectively protect the motor from burning out. It can stop when the material is full, only need to set the material time, no need for workers to take care of it, and has functions such as material level control, overload protection, and automatic feeding.

Technical Parameters

The hopper screw conveyor produced by Dahan Company are available in various models, and we can also customize them according to your needs.

| LS Type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX Type | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter(mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| pitch(mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Rotating speed(r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Delivery volume QΦ=0.33(m3/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| power Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| power Pd 1=30m(KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Rotating speed(r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Delivery volume QΦ=0.33(m3/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| power Pd 1=10m(KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| power Pd 1=30m(KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Rotating speed(r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Delivery volume QΦ=0.33(m3/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| power Pd 1=10m(KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| power Pd 1=30m(KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Rotating speed(r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Delivery volume QΦ=0.33(m3/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| power Pd 1=10m(KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| power Pd 1=30m(KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

Customized Types of Hopper Screw Conveyors

Hopper screw conveyors can be customized to meet the specific requirements of various applications. Here are some types of hopper screw conveyors that can be customized:

1. Tapered Hopper Screw Conveyor: This type of hopper screw conveyor is typically used when the bulk material being transported has poor flow properties. The hopper is designed with a gradually reducing cross-section, which helps to prevent material from bridging or clogging.

2. U-Trough Hopper Screw Conveyor: This type of hopper screw conveyor has a U-shaped trough that is used to contain the material being transported. The U-trough design helps to prevent material from spilling out of the conveyor during transport.

3. Vertical Hopper Screw Conveyor: This type of hopper screw conveyor is used to transport materials vertically. The hopper is typically mounted on a vertical support structure and the screw conveyor moves the material up the structure.

4. Heavy-Duty Hopper Screw Conveyor: This type of hopper screw conveyor is designed to handle heavy-duty applications. The screw conveyor is typically made of heavy-duty materials such as hardened steel and the hopper is reinforced to withstand the weight of the material being transported.

5. Sanitary Hopper Screw Conveyor: This type of hopper screw conveyor is designed for applications where cleanliness and hygiene are critical. The conveyor is typically made of stainless steel and is designed to be easy to clean and sanitize.

Overall, hopper screw conveyors can be customized to meet the specific needs of various applications. Customizations can include changes to the hopper design, screw design, and support structure, as well as the addition of features such as covers, discharge spouts, and sensors.

Video

Structure of the Hopper Screw Conveyor

Hopper screw conveyor is mainly composed of feeding port, spiral blade, cylinder, driving device, discharge port and so on. During operation, after the material is conveyed to the shell of the hopper screw conveyor through the feeding port, the material is subjected to the centrifugal force and the frictional force of the pipe wall in the internal spiral groove, rotates together with the spiral blade, and moves along the spiral groove under the action of gravity. Sliding down, so that the material is continuously pushed forward and conveyed, and finally evenly discharged from the discharge port.

Application

Hopper screw conveyor is mainly used for powder and granule feeding. It is suitable for feeding equipment with certain high requirements. It can be used with various specifications of extruders, high-speed mixers and plastic mixers.

Solutions by Industry

-

Hopper Screw Conveyor with dust-free feeding station

Conveying material: flour

Recommendation: Stainless steel Hopper Screw Conveyor with dust-free feeding station

Recommended reason: Will flour or other seasoning powders be scattered everywhere in the flour factory or food processing factory? Using stainless steel Hopper Screw Conveyor and dust-free feeding station, advantage one: all are 304 food grade stainless steel, safe and hygienic, no pollution; advantage two: the feeding platform is in a negative pressure state, no dust leaks and dust-free feeding, powder feeding process No loss; Advantage 3: Hopper Screw Conveyor's silo flange structure can be connected with a dust-free feeding station to increase the flour holding capacity, enabling continuous, uniform and rapid feeding, reducing a lot of manual input.

-

Hopper Screw Conveyor with mixer

Conveying material:animal feed

Recommended: Stainless Steel Hopper Screw Conveyor

Recommended reason: In order to ensure adequate nutrition in animal feed, a variety of nutrients need to be added to it. Through feeding equipment and stainless steel Hopper Screw Conveyor, one or more feed raw materials can be fed into the mixer at the same time to complete the feeding and mixing of animal feed. material device.

-

Hopper Screw Conveyor with vibro siever

Processing material: dehydrated garlic powder

Recommended: 304 stainless steel Hopper Screw Conveyor, 304 stainless steel vibro siever

Recommended reason: Dehydrated garlic powder is widely used in soups, sauces, seasonings, mixes, meat products, canned meats, biscuits, snacks, cheese, cream sauces, etc. After the dried garlic is pulverized by the pulverizer, it is directly transported to the vibro siever by the Hopper Screw Conveyor, and the incompletely pulverized garlic cloves or agglomerated garlic powder are screened out to ensure the quality and taste of the garlic powder. The Hopper Screw Conveyor's silo can receive a large amount of garlic powder and transport it to the vibro siever quickly, continuously and evenly, and the whole process of sealing will not cause garlic powder pollution or waste.

Hopper Screw Conveyor manufacturers:

Dahan Machinery has been focusing on the production of Hopper Screw Conveyor for 15 years, we have professional production workshops (lathes, milling machines, boring machines, drilling machines), designers, engineers, as well as assembly workshops, painting workshops, warehouses, etc. Hopper Screw Conveyor can be used to convey powdery, granular and small block materials, widely used in: feed mills, food processing plants, flour mills, chemical plants, etc. It can be used in conjunction with packaging machines, mixers, and feeders.

We can provide you with Hopper Screw Conveyor drawing design, guide selection, after-sales maintenance and other services.