Inclined Auger Conveyor

The motor speed and power increase with the increase of the tilt angle, and the tilt angle is usually 0-45° from the horizontal plane

Conveying angle: ≤60°

Conveying capacity: 142 cubic meters per hour

Conveying length: 60 meters

Common applications for inclined screw conveyors are cement mixers, feedlot dispensers, and spice and meat processing applications.

Introduction of Inclined Auger Conveyor

Inclined auger conveyor usually runs from a slightly higher than horizontal position to a 45-degree angle to the horizontal position, which should be determined according to the site conditions. With the increase of the inclination degree, the motor power and the thickness of the pipe wall should increase correspondingly, and the length should not exceed 6 meters.Inclined auger conveyors adapt well to plant layouts and reduce the number of equipment in the process flow. Typical applications for inclined screw conveyors include receiving and transferring bulk material from screens, mixers or as part of a discharge packaging system.

Each inclination angle of the inclined auger conveyor will reduce the conveying efficiency and conveying volume. It is necessary to increase the motor power and screw torque through precise design to ensure efficient conveying. In the actual use process, it is wrong to blindly pursue too large inclination angle, please ask the manufacturer to choose the product according to your conveying situation.

Inclined Auger Conveyor's Angle

The inclination angle of the axial tubular screw conveyor: about 45°, and the inclination angle of the shaft U-shaped screw conveyor: about 20°-30°.

The inclination angle of the shaftless tubular screw conveyor: about 30°, and the inclination angle of the shaftless U-shaped screw conveyor: about 20°-30°.

Tip: For materials with poor fluidity, the inclination angle can reach 50°, but to convey materials in various ways, it is necessary to apply a certain pressure to the feed port to squeeze the material into the conveying body, and the bottom bearing of the equipment needs to withstand Huge pressure, the bearing is easily damaged.

Video

Movable stainless steel inclined auger conveyor display

The inclined auger conveyor is connected to the packaging machine for use (45°inclination)

The relationship between the change of the inclination angle of the screw conveyor and the loss rate of the conveying efficiency:

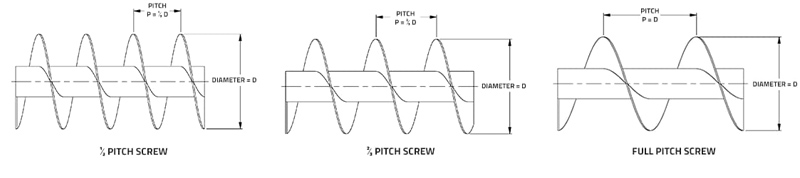

10° inclination angle: the loss of conveying efficiency is minimal, and the standard pitch inclined conveyor can meet the conveying requirements.

10°~20° inclination angle: The loss of conveying efficiency is between 10% and 40%. Use 2/3 pitch screw to reduce the loss. The loss efficiency can also be compensated by increasing the motor power and screw speed to avoid the material falling back.

20°~30° inclination: the loss of conveying efficiency is usually between 10% and 70%, it is recommended to use a screw conveyor with a tubular casing and a reducing screw (1/2 or 2/3), also need to increase the screw speed and motor power to reduce losses.

30°~45° inclination: the loss of conveying efficiency is often between 30% and 90%, it is recommended to use screw conveyor with tubular casing and reducing screw (1/2 or 2/3) and larger diameter, need to improve Helical speed and motor power to reduce losses.

Of course, the screw speed of the large inclination angle needs to be controlled and cannot be accelerated indefinitely. Too fast screw speed will cause the material to be thrown away and affect the transportation and production safety.

Table of inclination angle coefficient and material resistance coefficient of inclination screw conveyor (both products and materials under ideal conditions):

| Inclination coefficient table | |||||

| Inclination angle β | 0° | ≤5° | ≤10° | ≤15° | ≤20° |

| Correction coefficient of conveying volume when screw conveyor is inclined(inclined angle coefficient) C | 1.0 | 0.9 | 0.8 | 0.7 | 0.5 |

| The above inclination coefficients are only used for small-angle inclinations, and actual measurement is required for large-inclination-angle transportation. | |||||

| Material resistance coefficient table | ||

| Material characteristics | Typical example of material | Material resistance coefficient ω0 |

| dry, unrefined | Grain, grain, sawdust, coal dust, flour | 1.2 |

| wet, unpolished | Cottonseed, Malt, Sugar Cubes, Quartz Powder | 1.5 |

| semi-speculative | Soda ash, coal, salt | 2.5 |

| pondering | Pebble, sand, cement, coke | 3.2 |

Features and Benefits

1. It is suitable for inclined conveying materials within a range of 45°, and occupies a small area.

2. The conveying volume can reach 142 cubic meters per hour, which can realize long-distance conveying of 4-70 meters.

3. The speed is fast and the conveying is uniform, which can ensure that the material is not blocked during the conveying process.

4. Good sealing performance, basically no dust pollution, material spillage, etc. will occur during the entire conveying process, which improves the operating environment.

5. The material flow can be controlled by the loading and unloading gate.

Structure of Inclined Auger Conveyor

1. Inclined auger conveyor is a non-basic fixed type. It is connected by the helical body of the casing tube of the drive motor reducer and combined into a whole.

2. The shaft end is connected with the helical involute spline (or rectangular spline), which is easy to assemble and disassemble, has a large bearing capacity, and is safe and reliable.

3. The conveyor shell is connected by steel pipes through flanges to connect each section as a whole, so it has good overall rigidity, so that the working position and working posture can be selected at will, and it can be disassembled and moved at will.

4. The inlet and outlet can be made into the required inclination angle according to the situation of the work site, and the connection with other supporting equipment can be fixed.

Technical Parameters

| LS Type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX Type | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter(mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| pitch(mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Rotating speed(r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Delivery volume QΦ=0.33(m3/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| power Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| power Pd 1=30m(KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Rotating speed(r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Delivery volume QΦ=0.33(m3/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| power Pd 1=10m(KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| power Pd 1=30m(KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Rotating speed(r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Delivery volume QΦ=0.33(m3/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| power Pd 1=10m(KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| power Pd 1=30m(KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Rotating speed(r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Delivery volume QΦ=0.33(m3/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| power Pd 1=10m(KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| power Pd 1=30m(KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

The various types of inclined auger conveyors produced by Dahan Company are available. If you have special needs, we will design them free of charge according to your actual situation.

Application

Inclined auger conveyor is widely used in building materials, metallurgy, chemical industry, electric power, coal, machinery, light industry, food and other industries, suitable for conveying powdery, granular, small block materials, such as cement, coal powder, grain, fertilizer, ash , sand, coke and other materials whose temperature is less than 200 ℃.

Solutions by Industry