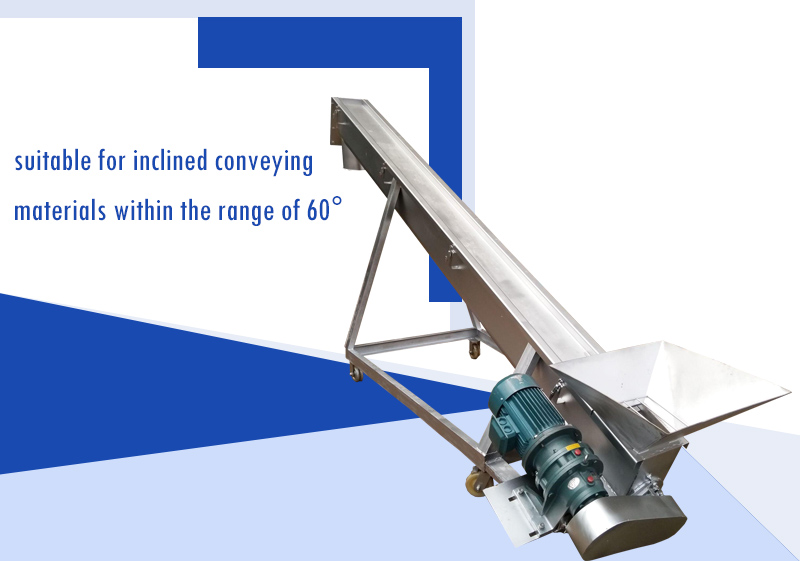

Inclined Screw Auger Feeder

Inclined conveying of various bulk materials

Tilt angle: 0-60 degrees

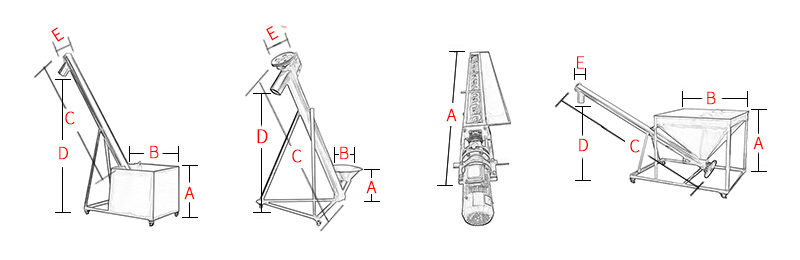

Conveying Length: Length: ≤20m

Conveying capacity: 142 cubic meters per hour

Suitable for conveying powdery, granular and small block materials, such as cement, pulverized coal, grain, fertilizer, ash, sand, coke, etc.

Introduction of Inclined Screw Auger Feeder

Inclined screw auger feeder is suitable for inclined conveying of various bulk materials, and the inclination angle should not exceed 60 degrees. When using inclined screw conveyor to convey materials, it depends on the arching characteristics of the material, and the material in the machine groove is subject to the thrust of the screw in the direction of movement. , the lower part is continuously fed to prevent the upper material from sliding down, and the lateral pressure is generated, thereby increasing the internal friction of the material. When the internal friction between the materials is greater than the external friction between the material and the groove wall and the weight of the material, the material will follow the spiral. The sheet is transported upward to form a continuous material flow, which can realize the transportation of materials with a large slope, and is often used in conjunction with dust removal equipment.

Features and Benefits

1. It is suitable for inclined conveying materials within the range of 60°, and occupies a small area.

2. The conveying capacity can reach 142 cubic meters per hour, which can realize long-distance conveying of 4-60 meters.

3. It is composed of double motors, feeding motor, vibration motor and each switch control, which is not easy to block the material.

4. Store the material at the bottom of the hopper, take out the entire screw, and control the material flow through the upper and lower material gates.

Design and Manufacture Considerations for Inclined Screw Auger Feeder

Inclination from 10 degrees: There is a minimum loss of efficiency. A trough “U” type and a standard pitch are enough for this application. The minimal loss can be overcome increasing the rpm and outer diameter or reducing screw pitch.

Inclination from 10 to 20 degrees: Efficiency losses range increases from 10 to 40 %. Also, they can be overcome increasing rpm and outer diameter. It is required additional power to compensate gravity factor.

Inclination from 20 to 30 degrees: Efficiency losses range increases from 10 to 70%. It is recommended to use a tubular trough and a reduced-pitch (1/2 or 2/3) for this application.

Inclination from 30 to 45 degrees: Efficiency losses range increases from 30 to 90%. It is recommended to use a tubular trough and a reduced pitch (1/2 or 2/3) and a bigger outer diameter. It is required more speed ( rpm) and power to compensate gravity factor.

Technical Parameters

| LS Type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX Type | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter(mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| pitch(mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Rotating speed(r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Delivery volume QΦ=0.33(m3/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| power Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| power Pd 1=30m(KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Rotating speed(r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Delivery volume QΦ=0.33(m3/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| power Pd 1=10m(KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| power Pd 1=30m(KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Rotating speed(r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Delivery volume QΦ=0.33(m3/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| power Pd 1=10m(KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| power Pd 1=30m(KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Rotating speed(r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Delivery volume QΦ=0.33(m3/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| power Pd 1=10m(KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| power Pd 1=30m(KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

The inclined screw auger feeder produced by Dahan Company are available in various models, and we can also customize them according to your needs.

Application

Inclined screw auger feeder is widely used in building materials, metallurgy, chemical industry, electric power, coal, machinery, light industry, food and other industries, suitable for conveying powdery, granular, small block materials, such as cement, coal powder, grain, fertilizer, ash Slag, sand, coke and other materials whose temperature is less than 200℃.

Solutions by Industry

-

Metal powder auger conveyor site

Conveying material:metal powder

Recommended Equipment: Auger Conveyor