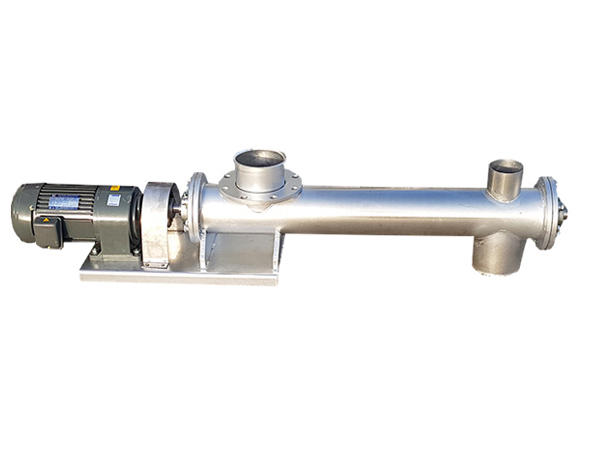

Micro Screw Conveyor

Designed for small feed rates and laboratory applications

Spiral diameter: 100-200mm

Conveying capacity: 3-22 cubic meters per hour

Conveying length: 2-5 meters

Micro screw conveyor is used for uniform and continuous feeding and unloading of small batches of powdery and granular materials

Introduction of Micro screw conveyor

Micro screw conveyors are ideal for micro-dosing applications, typically used in the production of chemicals and pharmaceuticals or any process that requires precise small quantities of additives. The diameter of the screw is 100mm-159mm, and the length (centre distance between import and export) is generally 100mm-2000mm. The conveying capacity is 0.01kg/h-1000kg/h, which is specially designed for small feeding speed and laboratory application.

Micro screw conveyors improve feeding accuracy by continuing to feed material into the outlet of the larger main screw feeder after the main feeder is closed, they are installed below the main screw feeder.

Function of Micro screw conveyor

The function of the micro screw conveyor is to precisely and accurately convey small quantities of material, usually ranging from a few grams to a few hundred grams. Here are some key features of the micro screw conveyor:

Metering and Batching: Can be used to deliver precise amounts of material to specific locations, ensuring the correct amount of material is used in the process.

Mixing: It can be equipped with mixing paddles or other devices to ensure that the materials are fully mixed before being conveyed to the next stage of the process.

Packaging: Can be designed to feed material directly to the packaging machine, ensuring that the package is filled with the correct amount of material.

Laboratory Applications: Typically used in a laboratory setting for handling small amounts of material. Screw conveyors can be used to convey material samples for testing and analysis, ensuring that the correct amount of material is used during testing.

Technical Parameters

| LS type | GX type |

Delivery QΦ=0.33 (m3/h) |

Power Pd 1=10m (KW)) |

Power Pd 1=30m (KW) |

Revolving speed (r/min) |

Delivery QΦ=0.33 (m3/h) |

| 100 | 2.2 | 1.1 | 1.6 | 120 | 1.9 | |

| 160 | 7.6 | 1.5 | 2.8 | 90 | 5.7 | |

| 200 | 200 | 11 | 2.2 | 3.2 | 75 | 18 |

| 250 | 250 | 22 | 2.4 | 5.3 | 75 | 18 |

| 315 | 300 | 36.4 | 3.2 | 8.4 | 60 | 29.1 |

The various types of micro screw conveyors produced by Dahan Company are available. If you have special needs, we will design them free of charge according to your actual situation.

Features and Benefits

1. The conveying capacity is between 3-22 cubic meters per hour, which is suitable for continuous feeding of small batches of powdery materials.

2. Small diameter and fast rotation speed can ensure uniform transportation of materials, and materials are not easy to be blocked. A loading and unloading gate can also be installed to control the flow of materials.

3. The whole conveying work is carried out in the pipeline, which avoids the pollution of dust to the environment and improves the working conditions at the same time.

4. The size is usually smaller than other types of conveyor systems, which makes them ideal for applications where space is limited. They can also be easily integrated into existing production lines.

5. Usually less expensive than other types of conveyor systems, especially for small applications. This makes them an economical choice for manufacturers who need to precisely transport small quantities of material.

Video

Options & Accessories

3 sizes available; feed rates from 1.5dm3/h to 630dm3/h (0.05 to 22 cfh)

Internal geometry of the body guarantees free flow

Minimal clearance between screw flight and feed tube ensures high-precision feeding

Different types of screws

Feeding propeller

Flanged connections

Application

Micro screw conveyors are mainly used in small production occasions and laboratories, and can reliably and accurately feed various dry solid materials with a very small footprint.

Solutions by Industry

Here are some general examples of how micro screw conveyors have been used by customers in different industries:

Pharmaceutical research laboratory: A pharmaceutical research laboratory may use a micro screw conveyor to handle small quantities of powders and granules for testing and analysis. The conveyor may be used to precisely meter and dose small amounts of materials for use in experimental procedures.

Food processing facility: A food processing facility may use a micro screw conveyor to transport small quantities of ingredients, such as spices, flavorings, and colorings, in the production of food products. The screw conveyor may be designed to handle a variety of food materials and may be integrated with other equipment such as mixers and packaging machines.

Chemical manufacturing plant: A chemical manufacturing plant may use a micro screw conveyor to transport small quantities of powders and granules in the production of chemical products. The conveyor may be used for the metering and dosing of additives and colorants, as well as for the packaging of small quantities of materials.