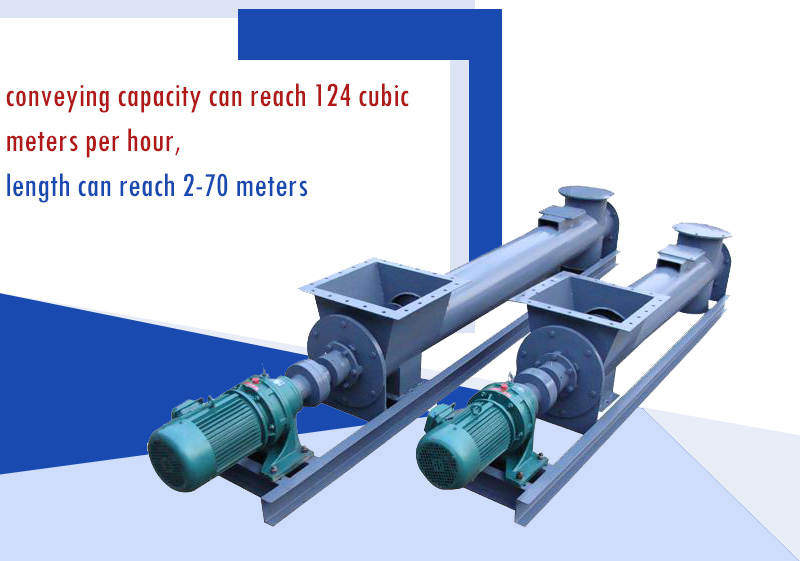

Pipe Screw Conveyor

Pipe screw conveyor is to use the motor to drive the screw to rotate in the sealed pipeline to move the material, and transport the product from one place to another. It is suitable for horizontal, inclined and vertical conveying of powder or granular materials.

Diameter: 100-1250mm

Conveying length: 2-70 meters

Conveying capacity: 142m³/h

Angle of inclination: 0-90°

Contact part material:Mild steel,SUS304 or SUS316L

Application: It can be used to convey powder, granular or small block series materials in industry, food environmental protection, medicine and other industries.

Introduction of Pipe Screw Conveyor

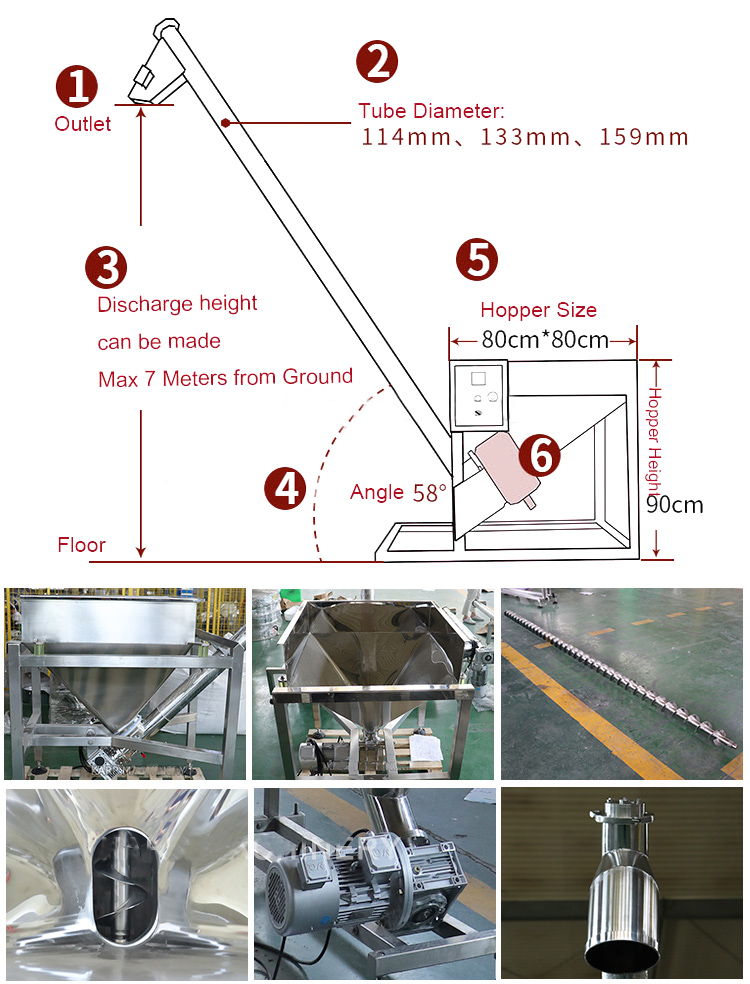

Pipe screw conveyor is a spiral bulk material transportation system that transports materials from one place to another through a rotating screw shaft in a sealed pipeline. It can transport raw materials to processing areas located at different levels of the facility or from these Zones carry raw materials, these conveyors are inclined at different angles to lift and convey material up and down the floor economically, they require enough space and more power to lift the material, depending on the steepness of the angle.

Pipe screw conveyor screw diameter from 100mm to 1250mm, a total of 12 specifications, divided into two forms of single drive and double drive, the maximum length of the single drive screw machine can reach 40m (super large 30m), the double drive screw machine adopts the middle disconnected shaft Structure, the maximum length can reach 80m (extra-large 60m), the length of the screw machine is every 0.5m in one gear, which can be selected according to needs, and the hourly conveying capacity is 1.2-142m³/h.

Technical Parameters

| Model |

Spiral diameter (mm) |

Screw-pitch (mm) |

Speed (r/min) |

Capacity (m³/h) |

| LS-100 | 100 | 100 | 140 | 2.2 |

| LS-160 | 160 | 160 | 112 | 7 |

| LS-200 | 200 | 200 | 100 | 13 |

| LS-250 | 250 | 250 | 90 | 22 |

| LS-315 | 315 | 315 | 80 | 31 |

| LS-100 | 100 | 355 | 71 | 56 |

| LS-500 | 500 | 400 | 63 | 98 |

| LS-630 | 630 | 450 | 50 | 140 |

| LS-800 | 800 | 500 | 40 | 300 |

| LS-1000 | 1000 | 560 | 32 | 280 |

| LS-1250 | 1250 | 630 | 25 | 380 |

The various types of pipe screw conveyors produced by Dahan Company are available. If you have special needs, we will design them free of charge according to your actual situation.

Features and Benefits

1.Versatility: Can be used to convey a variety of materials, including powders, granules and liquids. They can be customized to meet application specific needs such as length, diameter and angle of inclination.

2.Efficient: It can transport materials at high speed over long distances. They are simple in design and require minimal maintenance, making them a cost-effective material handling solution.

3.Gentle Handling: Ideal for fragile, abrasive or sticky materials that require gentle handling during transport. The screw design ensures smooth, even material movement, reducing the risk of damage or breakage.

4.Space-saving: The compact design can be installed vertically or horizontally, making it ideal for applications where space is limited.

5.Customizable: Pipe screw conveyors can be customized to meet the specific needs of an application. They can be designed to handle materials of different sizes and densities and can be equipped with various functions such as heating, cooling or dust extraction.

Application

Pipe screw conveyors offer a wide range of standard solutions for the handling of powdery or granular materials, the following are some specific applications for pipe screw conveyors:

Food Industry: Typically used in the food industry for conveying flour, sugar, spices and other dry or wet ingredients. They are also used to convey finished products such as treats, cereals and pet food.

Chemical industry: used in the chemical industry to transport powder, granule, liquid and other chemicals. They are also used to transport hazardous materials such as acids, alkalis and flammable substances.

Pharmaceutical industry: Used in the pharmaceutical industry to convey ingredients such as powders, granules and liquids. They are also used to deliver finished pharmaceutical products such as tablets, capsules and syrups.

Mining industry: used in the mining industry to transport materials such as coal, minerals and ores. They are available for horizontal and vertical transport and can be customized to meet the specific needs of the application.

Waste management industry: used in the waste management industry to transport materials such as municipal waste, industrial waste and sewage sludge. They can be used for horizontal and vertical transport and can be equipped with features such as heating or cooling to handle different types of waste.

Video

Pipe screw conveyor for grain

Pipe screw conveyor for feed

Structure of the Pipe Screw Conveyor

Options

Pipe screw conveyors can be customized to meet the specific needs of an application, and there are a variety of options that can be added to the conveyor to optimize its performance. , the choice of option will depend on the specific needs of the application, such as the type of material being transported, the distance and angle of transport, and the desired throughput rate.

Variable Frequency Drives: A variable frequency drive (VFD) can be added to the conveyor to control the speed of the screw for precise control of material flow.

Hopper: A hopper can be added at the inlet of the conveyor to control the feeding of material into the conveyor.

Dust removal: A dust removal system can be added to capture and remove any dust or airborne particles generated during material transport.

Heating or Cooling: Heating or cooling systems can be added to maintain the temperature of the material during transport.

Covers: Covers can be added to conveyors to prevent dust or other contaminants from escaping during transport and to protect materials from external contaminants.

Inspection port: An inspection port can be added to facilitate the inspection of the screw and facilitate maintenance and cleaning.

Flexible Links: Flexible links can be added to allow for movement and flexibility of the conveyor system.

Solutions by Industry

The following are three customer cases of pipe screw conveyor:

Case 1:

A food processing company in Europe was producing a range of snack foods and needed a reliable conveyor system to transport ingredients such as flour, sugar and spices. They invested in a pipe screw conveyor that was custom-built to meet the specific needs of their application, including stainless steel construction, a flexible screw design for gentle handling of raw materials, and a hopper for controlled feed. The pipe screw conveyor helps to increase the efficiency of the production line, thereby increasing output and reducing waste.

Case 2:

A chemical manufacturer in Asia needed a conveyor system to transport powders and granules such as calcium carbonate, titanium dioxide and talc. They opted for a pipe screw conveyor, custom-made with a belt flight design to prevent breakage of fragile materials, and a dust removal system to prevent dust emissions during transport.

Case 3:

A mining company in South America is transporting ore such as copper, gold and silver from a mine to a processing plant. They invested in a custom-built pipe screw conveyor with heavy-duty construction, a high-capacity design for efficient ore transport, and a flexible screw design to prevent material damage.