Plastic Screw Conveyor

A screw conveyor designed with plastic components, such as plastic screws and plastic tubes, typically used in applications where corrosion or chemical resistance is required, or where the material being conveyed may be abrasive or prone to sticking, commonly used in Poultry industry, farms transport poultry manure

Conveying capacity: 142 cubic meters per hour

Length: 60 meters

Angle: 0-90 degrees

Plastic screw conveyor is used to transport animal manure in chicken houses, duck houses, pig farms and other occasions in the poultry industry

Introduction of Plastic Screw Conveyor

Plastic screw conveyor is made of polypropylene PP material. Compared with metal auger, it has better corrosion resistance, can effectively avoid reaction with corrosive materials, and has a longer service life. Mainly used in chicken coops, duck coops, cattle farms, pig farms, etc. that need to transport animal manure, the manure removal speed is fast, time-saving and labor-saving, well sealed, the manure removal is clean, Animal manure can be transported to manure pits, manure trucks or other locations without the need for manpower.

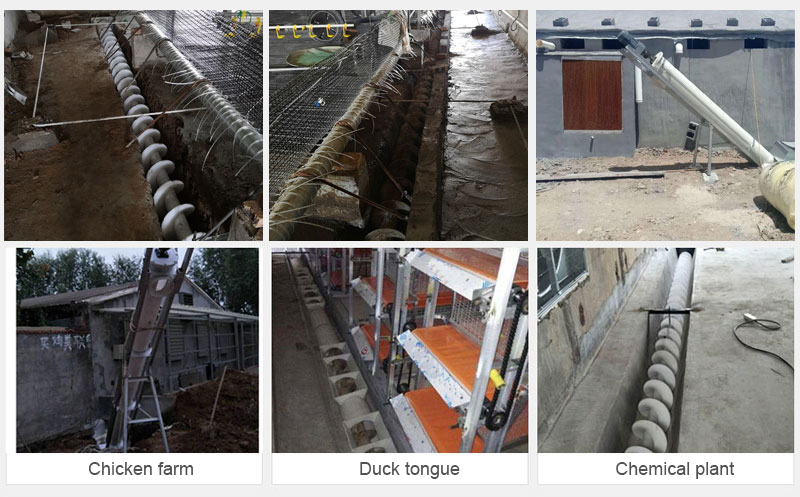

Application

The plastic screw conveyor is specially used in the breeding industry. It is mainly used to transport animal manure in chicken farms, duck farms, pig farms, cattle farms and other occasions. The manure can be directly transported to the plastic screw conveyor through the manure cleaning conveyor belt, and then conveyed by the conveyor Conveying to the manure heap, it has strong milk corrosion, and prevents the conveying material from deteriorating and causing damage to the conveyor. The whole process is fully automated without manual participation, which is faster and easier. Compared with traditional metal conveyors, the cost is low, the efficiency is high, and the profit is more considerable.

In addition, plastic screw conveyors can also be used in other industries:

Chemical Processing: For the transfer of corrosive chemicals and other materials. The corrosion-resistant properties of plastic make it an ideal material of choice for these applications.

Food Processing: For conveying powders, grains and other dry materials. The smooth surface of plastic screws and pipes reduces the risk of contamination and is easy to clean.

Wastewater treatment: used to transport sludge and other waste materials. Plastic's wear-resistant properties make it an ideal material of choice for these applications.

Pharmaceutical Manufacturing: For conveying powders and other materials. The smooth surface of plastic screws and pipes reduces the risk of contamination and is easy to clean.

Agriculture: Used to transport grain, seeds and other crops. Plastic's lightweight and corrosion-resistant properties make it an ideal material of choice for these applications.

Video

The Plastic Screw Conveyor is embedded in the ground to transport animal waste into the manure pit

Plastic Screw Conveyor inclined conveying animal manure into manure truck

Features and Benefits

1. Corrosion resistance: It has strong corrosion resistance to chemicals, acids and other corrosive materials, and can be used to transport chemical raw materials, fluorescent powder, poultry manure and other strong acid and strong alkaline materials.

2. Wear resistance: It also has high wear resistance, which makes it an ideal choice for conveying abrasive materials such as sand, gravel and minerals.

3. Low maintenance cost: Compared with other types of screw conveyors, plastic screw conveyors require the least maintenance because the plastic parts are very durable and do not require lubrication.

4. Light weight: The weight is usually lighter than other types of screw conveyors, which makes them easier to transport and install.

5. Customizable design: Can be designed to meet the specific requirements of the application, including the type of plastic used, the size and shape of the screw, and the diameter and length of the pipe.

working principle

The plastic screw conveyor generates power through the motor. After being decelerated by the reducer, it drives the screw to rotate. After the animal manure enters the spiral pipe, the plastic screw conveyor drives the chicken manure forward through the spiral rotation and transports it to the designated direction.

Technical Parameters

The various types of plastic screw conveyors produced by Dahan Company are available. If you have special needs, we will design them free of charge according to your actual situation.

| LS Type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX Type | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter(mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| pitch(mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Rotating speed(r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Delivery volume QΦ=0.33(m3/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| power Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| power Pd 1=30m(KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Rotating speed(r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Delivery volume QΦ=0.33(m3/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| power Pd 1=10m(KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| power Pd 1=30m(KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Rotating speed(r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Delivery volume QΦ=0.33(m3/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| power Pd 1=10m(KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| power Pd 1=30m(KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Rotating speed(r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Delivery volume QΦ=0.33(m3/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| power Pd 1=10m(KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| power Pd 1=30m(KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

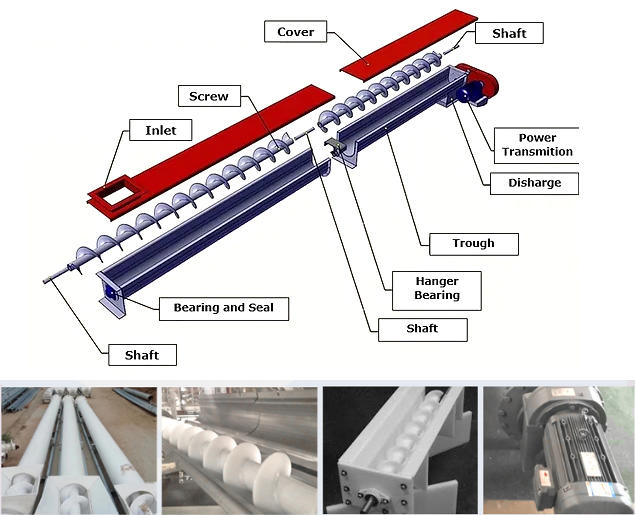

detail structure

Plastic screw conveyors consist of several key components that work together to transport material from one location to another.

Plastic Screw: The plastic screw is the main component of the conveyor and moves the material along the length of the conveyor. Screws are usually made of high-strength plastic materials, such as polyethylene or polypropylene, which are resistant to wear and corrosion.

Plastic Tube: The plastic tube is the casing that surrounds the screw and contains the material being conveyed. Tubing is usually made of the same plastic material as the screw and is available in a variety of diameters and lengths to meet the specific requirements of the application.

Inlet and Outlet: The inlet is the opening at one end of the conveyor, where material enters the system, and the outlet is the opening at the other end of the conveyor, where material exits the system. The size and shape of the inlet and outlet can be customized to meet the specific requirements of the application.

Drive Assembly: The drive assembly is the mechanism that powers the screw and moves material along the length of the conveyor. The drive assembly usually consists of an electric motor and a gearbox that converts the rotary motion of the motor into linear motion of the screw.

Supporting Structure: The supporting structure is the frame that holds the conveyor in place and provides stability during operation. The support structure can be customized to meet the specific requirements of the application, including the height and angle of the conveyor.

Solutions by Industry

Why choose plastic screw conveyor?

Today, when metal screw conveyors are mature and widely used, why choose plastic screw conveyors? As a manufacturer, we can give you three reasons:

1. Mature and perfect plastic processing technology. The rapid development of plastic processing makes the performance, shape shaping and plastic welding of plastic easy, which provides a good basic condition for the production and processing of plastic screw conveyor.

2. The versatility and superior performance of plastics. There are various types of plastics, and different types of plastics have different properties. Some plastic materials even have better corrosion resistance than metal, and animal manure is more corrosive. Plastic screw conveyor can better withstand the corrosion of animal manure without deformation or damage. For animal waste, metal screw conveyors that are prone to rust due to long-term humid environments are difficult to compare with plastic screw conveyors.

3. More portable machine and less cost. Thanks to the rapid development of the plastic industry and the lightness of the plastic itself, although the total weight of the plastic screw conveyor is lower than that of a metal screw conveyor, its conveying performance is not inferior to that of a metal conveyor, and it requires less cost.

Two common animal manure treatment schemes and the application of plastic screw conveyor

1. Water flushing method: set drainage and defecation ditches in front of the breeding pen, place the plastic screw conveyor in the ditch, and use water to flush the animal feces into the plastic screw conveyor at the height of the breeding pen with a certain slope, and the plastic screw conveyor The diluted animal manure is sent directly to the compost tank. The existence of the plastic screw conveyor greatly reduces the residue of animal manure and labor intensity.

2. Mechanical cleaning: Use scrapers or other mechanical equipment to transport animal manure to the designated location, and then use the plastic screw conveyor to uniformly transport and process the accumulated animal manure. It is usually used in large-scale breeding farms. The plastic screw conveyor realizes the automatic manure cleaning process without manual operation in the whole process.