Portable Belt Conveyor

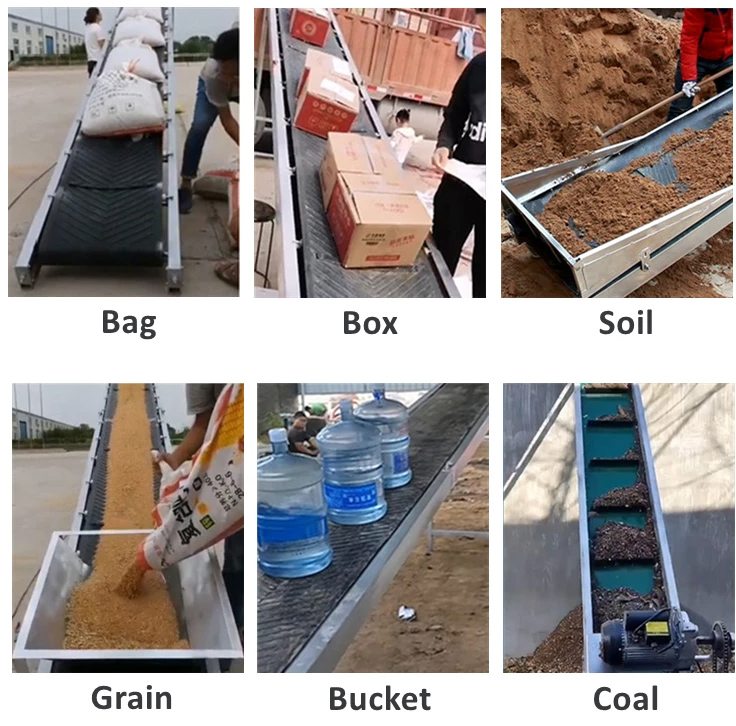

Designed to transport a wide range of materials from small packages to bulk materials. Its portability and flexibility make it ideal for a variety of industries, including construction, manufacturing, warehousing and logistics.

Belt width: 300-1200mm

Length: 5-30

Conveying capacity: 278 cubic meters per hour

Speed: 0.5 m/s-2.0 m/s

Application:Whether you are going up a steep slope or into a dump truck, moving material across flat ground, down a slope or digging underground, a portable conveyor system is the ideal choice.

Introduction of Portable Belt Conveyor

Portable belt conveyor is a common belt conveyor with moving wheels, which can be moved at will according to the stacking position of materials, and can be pushed into and out of the warehouse manually. It is mainly used for occasions where the loading and unloading places change.

Portable belt conveyor has two speeds of fast and full to meet the different requirements of bulk transportation and packaging. Side conduits are installed on both sides of the rack to prevent materials from scattering during transportation. stacking, loading and unloading operations.

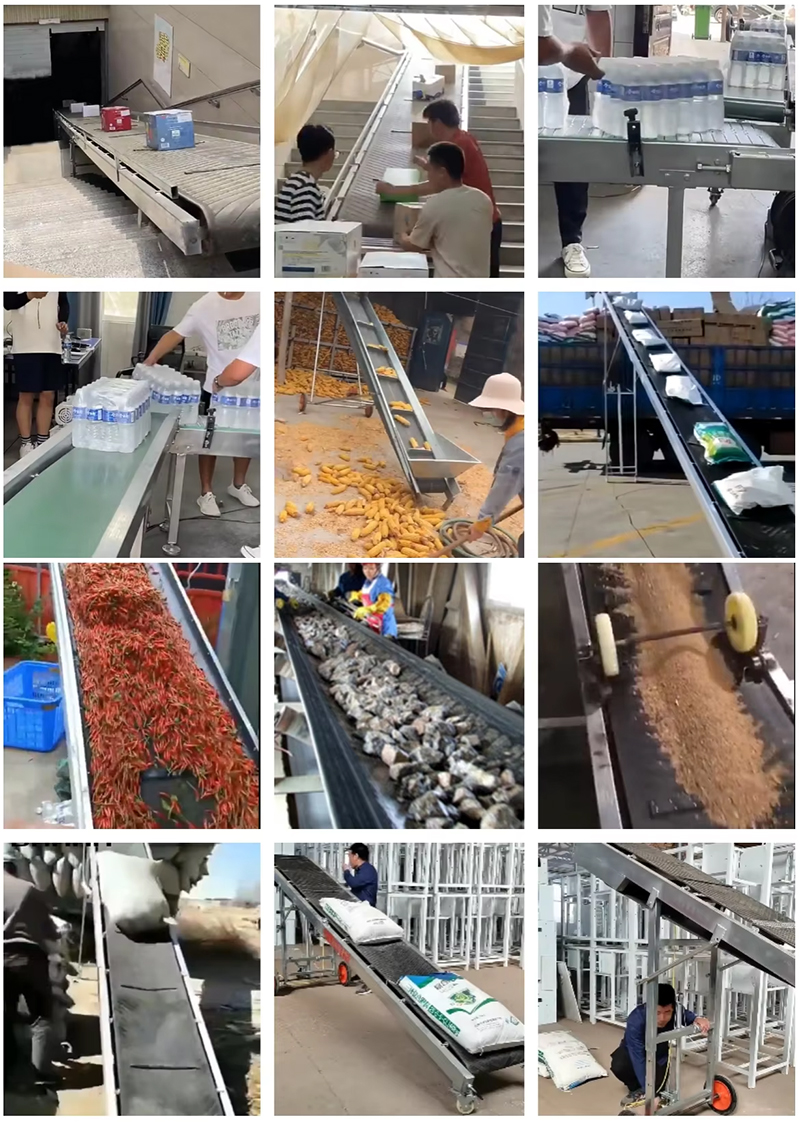

Portable Belt Conveyor Product Image

Types of Portable Belt Conveyor

There are several types of portable belt conveyors available, each designed to meet specific needs and applications. Here are some common types:

1. Lifting type: The lifting height can be adjusted according to the height of the silo or truck. It is often used to transport and unload bulk materials or finished items over short distances. Mobile lifting belt conveyors are generally equipped with two pneumatic tires and two universal wheels, which are flexible and convenient to move. Common lengths are 6 meters, 8 meters, 10 meters, 12 meters, etc., and widths are 500, 600, 650, 800mm. Other models can also be customized according to the special needs of users.

2. Telescopic type: also called portable loading conveyor, it can be freely expanded and contracted in the length direction, and the length of the conveyor can be controlled at any time. It can transport materials in both directions, and can be used in conjunction with other conveying equipment and material sorting systems to realize automated production of materials entering and exiting warehouses or vehicle loading and unloading.

Features and Benefits

1.Mobility: One of the key features of a portable belt conveyor is its mobility, allowing it to be easily moved from one location to another within a facility or between different sites.

Adjustable Length: Portable belt conveyors often come with adjustable lengths to accommodate different material handling needs and spatial constraints.

2.Foldable Design: Some portable belt conveyors have a foldable design, making them compact and easy to transport when not in use.

3.Variable Speed: These conveyors may have variable speed settings to control the flow of materials and adapt to different processing requirements.

4.Durable Construction: Portable belt conveyors are typically constructed with durable materials to withstand the rigors of industrial environments and frequent relocation.

Video

Difference between portable belt conveyors and fixed belt conveyors

Portable belt conveyors and fixed belt conveyors are two common types of material conveying equipment. They have significant differences in design, application scenarios and functions.

| Difference | Portable belt conveyor | Fixed belt conveyor |

| Structure | Modular design, easy to disassemble and assemble; simple structure; equipped with wheels or other mobile devices | Fixed structure, installed in a fixed position; complex structure, may have multiple functional components |

| Application scenarios | It is suitable for situations where the working environment is changeable and the conveying lines need to be adjusted frequently, such as construction sites, warehousing logistics, temporary material handling, etc. | Suitable for material transportation at fixed positions in production lines, such as assembly lines, etc. |

| Advantages | Flexible, portable, simple to operate, strong adaptability | Strong conveying capacity, diverse functions, high degree of automation |

| Disadvantages | Limited transportation distance, weak carrying capacity, relatively poor stability | Complex structure, difficult to move, poor flexibility |

The type of belt conveyor you choose depends mainly on the specific application scenario and requirements. If you need flexible and portable conveying equipment, a portable belt conveyor is a good choice; if you need large-scale, long-distance, and fixed-position conveying, a fixed belt conveyor is more suitable.

Technical parameters

|

Width (mm) |

Conveying length(m) Power(kw) |

Transfer speed (m/s) |

Delivery volume (t/h) |

||

| 400 |

≤10 3 |

12-15 3-4 |

15-30 4-7.5 |

1.25-2.0 | 30-60 |

| 500 |

≤10 3 |

12-15 4-5.5 |

15-30 5.5-7.5 |

1.25-2.0 | 40-80 |

| 650 |

≤10 4 |

12-15 7.5 |

15-30 7.5-11 |

1.25-2.0 | 80-120 |

| 800 |

≤10 4 |

12-15 7.5 |

15-30 7.5-15 |

1.25-2.0 | 120-200 |

| 1000 |

≤10 5.5 |

10-20 7.5-11 |

20-40 11-22 |

1.25-2.0 | 200-320 |

| 1200 |

≤10 7.5 |

10-20 7.5-15 |

20-40 15-30 |

1.25-2.0 | 290-480 |

| 1400 |

≤10 11 |

10-20 15-22 |

20-40 22-45 |

1.25-2.0 | 400-680 |

| 1600 |

≤10 15 |

10-20 22-30 |

20-50 30-75 |

1.25-2.0 | 600-1080 |

| 1800 |

≤10 18.5 |

10-20 30-45 |

20-50 45-110 |

1.0-2.0 | 800-1500 |

| 2000 |

≤10 22 |

10-20 45-55 |

20-50 55-132 |

1.0-2.0 | 1000-2000 |

| 2400 |

≤10 30 |

10-20 55-75 |

20-50 75-185 |

1.0-2.0 | 1500-3000 |

Structure of Portable Belt Conveyor

Portable belt conveyor is mainly composed of driving device, braking device, supporting part, tensioning device, redirecting device, cleaning device, loading device, unloading device and tape.

Conveyor belt: There are two common types of rubber belt or plastic belt. The rubber belt can be used in the working environment of -15~40℃, and the conveying material generally does not exceed 50℃. The plastic bag can have the advantages of oil resistance, acid and alkali resistance, etc.

Idler: There are groove idler, flat idler, self-aligning idler and buffer idler. The trough-shaped idler (composed of 2 to 5 rollers) supports the bearing branch and is used to transport bulk materials; the self-aligning idler is used to adjust the lateral position of the belt to avoid deviation; the buffer idler is installed at the receiving place to Reduce the impact of the material on the belt.

Roller: It is divided into two types: driving roller and reversing roller.

Tensioning device: enable the conveyor belt to achieve sufficient tension to avoid slippage.

Application

Loading and Unloading: Portable belt conveyors are commonly used for loading and unloading trucks, trailers, and containers in warehouses, distribution centers, and shipping yards.

Temporary Conveyor Solutions: They are ideal for temporary material handling needs, such as during construction projects, events, or temporary production setups.

Assembly Line Operations: Portable belt conveyors can be used in assembly line operations to move components or products between workstations or processes.

Mining and Agriculture: In industries like mining and agriculture, portable belt conveyors are used for transporting bulk materials, such as ores, grains, and agricultural products.

Portable Packaging Lines: They are also utilized in portable packaging lines for efficiently moving products to and from packaging stations.

Are there any specific factors to consider when choosing a portable belt conveyor?

When choosing a portable belt conveyor, there are several factors to consider to ensure it meets your specific needs and requirements. Here are some key factors to consider:

1.Application and Material: Consider the type of materials you will be conveying, their characteristics (such as size, weight, and shape), and the specific application requirements.

2.Capacity and Speed: Determine the required capacity and throughput of the conveyor. This includes considering the volume or weight of materials that need to be transported per unit of time.

3.Size and Dimensions: Evaluate the available space and layout constraints in your facility or worksite.

4.Mobility and Portability: Assess the mobility features of the conveyor, including the presence of wheels or casters for easy movement. Consider the weight and ease of setup and dismantling for transportation purposes.

Solutions by Industry

-

Grain Logistics Company

The client is a grain logistics company that needs to transport large quantities of grain from farm fields or warehouses to processing plants or terminals for export. They selected a portable belt conveyor with high capacity and adjustable height features. The portable design allowed them to quickly move the conveyor between different job sites, increasing transportation efficiency and flexibility.

-

Construction Company

A construction company is responsible for transporting large quantities of sand on a construction site. They chose a portable belt conveyor with a durable design and adjustable height features. The conveyor is able to move flexibly around the site, transporting sand from trucks or stockpiling areas to where it is needed.

-

Cement Production Plant

A cement production plant needs to transport cement from the production line to a warehouse or shipping area. Due to the weight and special properties of the cement, they chose a portable belt conveyor specifically designed for heavy-duty materials. The conveyor has a strong structure and durable belts capable of withstanding the weight and wear of the cement.