Poultry Feed Screw Conveyor

It is used for material conveying, feeding and other processing technologies in feed factories, such as pig feed, chicken feed, and straw feed processing lines. The hopper feeds the feed, and the feed is sent by the screw shaft to the discharge end of the conveyor, and the discharge end puts the feed into the bag. The part of the Poultry feed screw conveyor in contact with the material is made of stainless steel, and the material is completely free from contamination during the conveying process, which enables fully enclosed automation in the production process.

Length: 2-70 meters

Output: 134 cubic meters per hour

Tilt angle: 0-90°

Power: 1.1-55KW

-

Introduction of Poultry Feed Screw Conveyor

Poultry feed screw conveyor is used in the conveying and mixing of raw materials in the feed industry. The hopper of the screw conveyor feeds the feed, the screw shaft sends the plastic to the discharge end of the conveyor, and the feed is filled into bags at the discharge end. The feed screw conveyor can be arranged horizontally, inclined or vertically, and can be used alone or in combination with other machines, and can also be used in conjunction with other equipment to meet the conveying requirements of various industries.

Note: 304/316 stainless steel can be selected according to user requirements, which is more hygienic.

Features and Benefits

1. Only one feeder can feed multiple mixers at the same time, eliminating the trouble of manual feeding and making the feeding work safer, more time-saving and labor-saving.

2. The volume of the silo is 100-300KG, the conveying volume per hour can reach 100-3000KG, and the feeding height can reach 8 meters.

3. The inlet and outlet can be made into the required inclination angle according to the situation of the work site, and it can be connected and fixed with other supporting equipment.

4. The induction device can be installed to automatically control the material level of the material box of the supporting equipment and improve the automation level.

5. In order to facilitate the cleaning of residual materials, it is designed as follows: the screw can be reversed for discharging, the lower end of the material pipe has a gate for discharging, and the entire screw can be easily unloaded, loaded and cleaned without tools.

6. Both the silo and the conveying pipe are made of stainless steel (the material can be according to customer requirements) to ensure that the feed is completely pollution-free during the conveying process.

7. The fully enclosed structure can play a good role in dust prevention, and can effectively isolate those materials with high hygienic requirements or materials with strong odor.

8. According to various uses, installation positions, models, and conveying methods, the installation positions of reducers and motors can be diversified and unlimited.

Video

Poultry feed screw conveyor for conveying rice bran

Poultry feed screw conveyor for conveying wheat bran

Technical Parameters

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating Speed (r/min) |

Delivery Volume (m 3 /h) |

Rotating Speed (r/min) |

Delivery Volume (m 3 /h) |

Rotating Speed (r/min) |

Delivery Volume (m 3 /h) |

Rotating Speed (r/min) |

Delivery Volume (m 3 /h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Medium | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 3150 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

The poultry feed screw conveyor produced by Dahan Company are available in various models, and we can also customize them according to your needs.

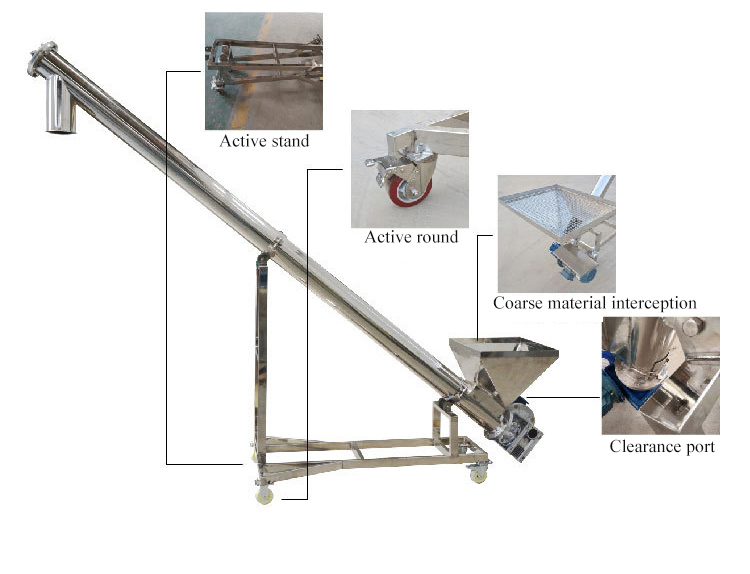

Structure of Poultry Feed Screw Conveyor

Poultry feed screw conveyor is mainly composed of driving device, casing, cover plate, screw shaft, screw blade, feed port, discharge port and other components.

Drive device: It consists of motor and reducer.

Spiral blade: can be divided into full blade type, belt blade type, paddle type, tooth type and so on.

Chassis: There are two types of "U"-shaped chassis and circular chassis. The circular chassis is mainly used for sealing equipment feed, and the auger of the circular chassis is also called the sealing auger.

Spiral Shaft: Hollow, made of steel pipe, high strength, light weight, easy to connect. Use a short length of solid shaft at the shaft-to-shaft connection and where the bearing is mounted. Extend the solid shaft into the hollow shaft at the connection, and use high-strength bolts to pass through the hollow shaft and the solid shaft in a mutually perpendicular direction to fix and connect the screw shaft.

Application

Poultry feed screw conveyors are commonly used in the poultry industry for the transportation of poultry feed materials such as grains, pellets, and powders. Here are some specific examples of how screw conveyors can be used in the poultry feed industry:

1.Transporting feed from storage to the feeding area: Screw conveyors can be used to move feed materials from the storage facility, such as a silo or hopper, to the feeding area in the chicken house. The screw conveyor can be designed to handle a variety of feed materials, and its size and capacity can be adjusted to match the volume of feed required by the chickens.

2.Mixing feed ingredients: Screw conveyors can also be used to mix different feed ingredients before they are delivered to the feeding area. The screw conveyor can be equipped with paddles or other mixing devices to ensure that the feed ingredients are thoroughly mixed before they are fed to the chickens.

Cases of conveying solutions we provide

The following are some examples that Dahan manufacturers can provide to illustrate how poultry farmers use screw conveyors to transport poultry feed in different environments:

-

Large commercial poultry farm

A large commercial poultry farm producing feed for thousands of chickens may use screw conveyors to transport feed materials from the storage facility to the feeding area. The screw conveyors may be integrated with other equipment such as mixers and cleaners to ensure that the feed is of a consistent quality. The system may be designed to handle large volumes of feed materials and may be automated for maximum efficiency.

-

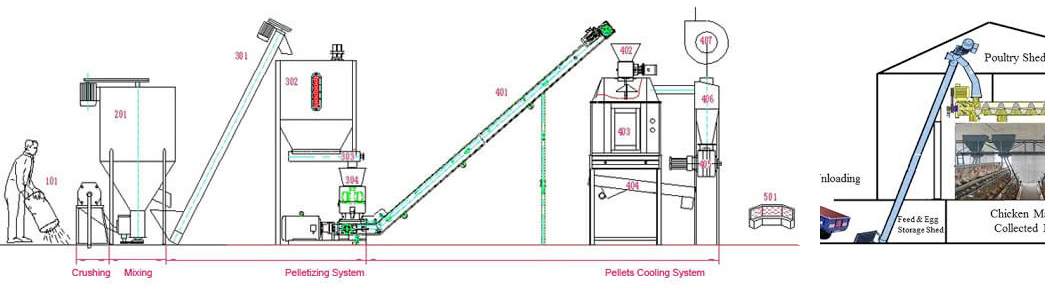

Feed mill

A poultry feed mill may use screw conveyors to transport feed materials between different stages of the production process. For example, the screw conveyor may be used to transport raw materials to the grinding stage, and then used again to transport the ground materials to the mixing stage. The system may be designed to handle a variety of feed materials and may be integrated with other equipment such as hammer mills, mixers, and pellet mills.

-

Small-scale family farm

A small-scale poultry farm that produces feed for a few dozen chickens may use a single screw conveyor to transport feed materials to the feeding area. The screw conveyor may be manually operated and designed to handle smaller volumes of feed materials.