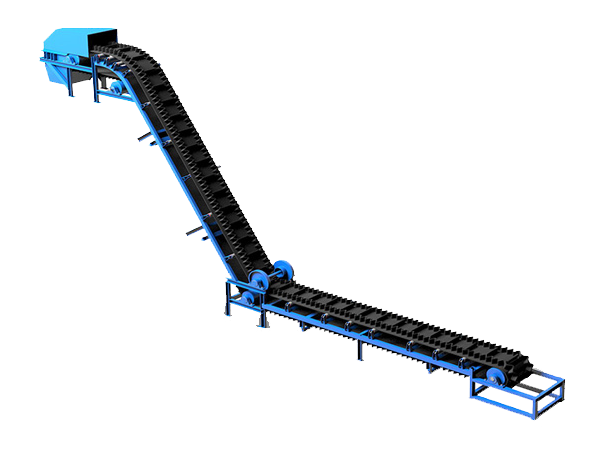

Scraper Conveyor

Continuous conveying equipment for bulk material conveying by means of a moving scraper chain in a closed rectangular housing. Suitable for short distances, medium slopes and underwater transport.

Slot width: 160/200/250/320/400mm

Conveying capacity: 600 cubic meters per hour

Conveying distance: 100 meters

Introduction of Scraper Conveyor

Scraper conveyor is a kind of conveying equipment that continuously conveys powder, granule and small block materials in a closed shell by means of a moving scraper chain. It is suitable for closed conveying, the conveying volume is not too large, the process layout is complicated, and multi-point feeding or multi-point discharging is required. Compared with the vertical screw conveyor, the conveying capacity is larger, the operation is relatively stable, and the temperature of the conveyed material generally does not exceed 180 °C.

Scraper conveyor uses the open chute as the bearing member of coal, gangue or material, etc., and fixes the scraper on the chain (composed of scraper chain) as the traction member. When the head drive part is started, the sprocket on the head shaft is driven to rotate, so that the scraper chain circulates and drives the material to move along the chute until it is unloaded at the head. The scraper chain bypasses the sprocket for a stepless closed cycle operation to complete the conveying of materials.

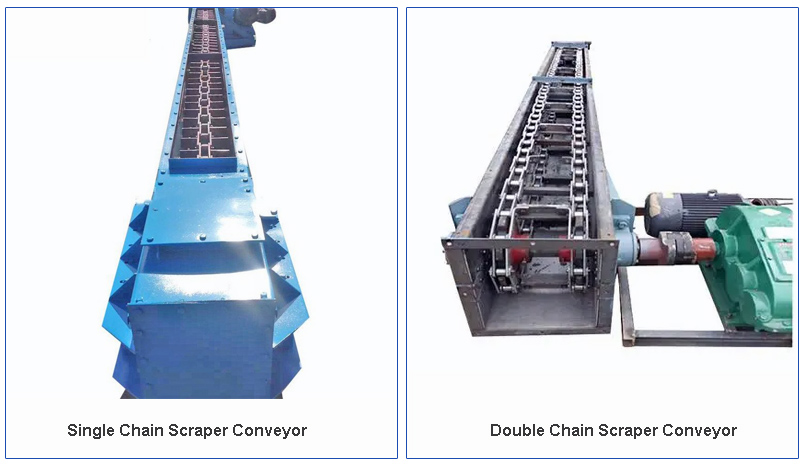

The difference between single-chain and double-chain Scraper Conveyor

Single Chain Scraper Conveyor means that a chain is located in the center of the scraper, and the scraper plays a guiding role in the middle groove to drive the conveying of materials.

Features: simple structure, flexible work, good flexibility. The chain is evenly stressed, wears less and runs smoothly.

Disadvantages: The material passing space is small, the transportation capacity is low, it is suitable for small conveying volume, and the machine head is large and occupies a large working space.

Double Chain Scraper Conveyor means that two chains are located at both ends of the scraper.

Features: The material passing space is large and the conveying capacity is strong, which is suitable for transporting bulk materials.

Disadvantages: prone to horizontal bending, uneven force on the chain, and large wear of the middle groove.

The difference between Scraper Conveyor and Screw coneyor

| main point | Scraper Conveyor | screw conveyor |

| Application Scenario | The application scenarios are complex and are mostly used in the coal industry and mining industry | The application scenario is relatively simple, and it is impossible to arrange overly complicated transmission lines |

| Conveying distance | Conveying distance up to 100m | The conveying distance is generally controlled within 20m |

| Delivery angle | Horizontal or less than 25° inclined conveying | Conveying in horizontal, inclined and vertical directions |

| Conveying materials | It is mostly used to transport coal, coal gangue, some stone materials, etc. | More conveying of small particles and powders |

| delivery volume | big | Small |

| Material delivery method | The chain pulls the scraper at a fixed distance, and the scraper pushes the material forward | Use the thrust of the screw, the friction of the material and the driving force of the subsequent material to complete the conveying |

Features and Benefits

1. It can transport powder, granules and small block materials horizontally or at a small inclination angle, and the horizontal conveying distance is long, up to 100 meters.

2. The structure is solid and can withstand the impact, impact, smashing, pressing and other external forces of coal, gangue or other materials.

3. It can be used for horizontal conveying or inclined conveying. When transporting upward along the inclination, the inclination angle of the coal seam shall not exceed 25°, and when transporting downward, the inclination angle shall not exceed 20°.

4. It can be multi-point feeding and multi-point discharging without any additional feeding or discharging device.

5. It can run in reverse, which is convenient to deal with the bottom chain accident.

6. The casing has good sealing performance, which can prevent the dust phenomenon during the conveying process of materials and reduce the pollution to the environment.

7. When there is no casing at the tail, and the scraper is put into the material pile, the material can be reclaimed and conveyed by itself.

Video

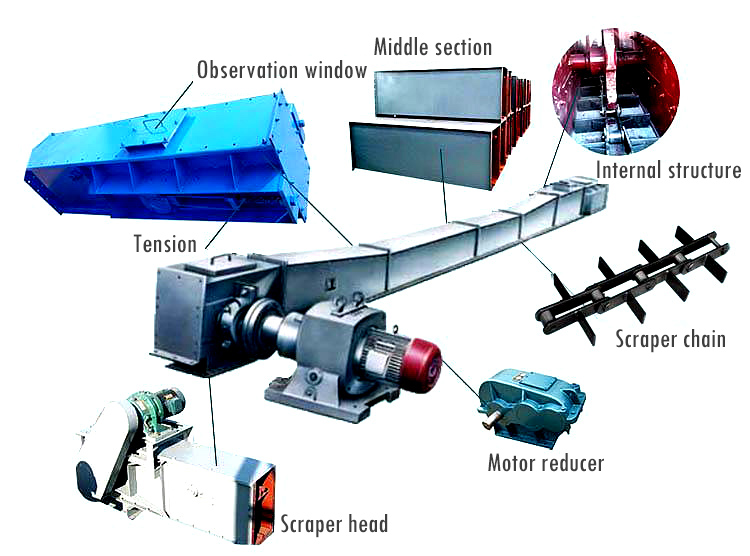

Structure of Scraper Conveyor

It consists of transmission system, nose frame, head wheel assembly, scraper chain, intermediate groove, discharge gate, tail frame, tail wheel assembly, tensioning device, etc.

The transmission system consists of a motor, a reducer and a coupling, which is the power part of the scraper conveyor. Due to the low speed of the scraper conveyor, the reducer usually adopts the NGW type planetary gear reducer. The arrangement of the transmission system has two basic forms, which can also be adjusted according to the site location. In order to facilitate installation, a chassis for installing the motor and reducer is designed under the transmission device.

The main function of the nose frame is to support the head wheel assembly.

The head wheel assembly consists of drive shaft, sprocket, bearing and sealing and lubrication system.

Technical parameters

| MS, GSS type horizontal scraper technical parameter reference table | |||||||||||||

| Model | 12 | 16 | 18 | 20 | 25 | 30 | 32 | 35 | 40 | 50 | 60 | 63 | |

| Slot width(mm) | 120 | 160 | 180 | 200 | 250 | 300 | 320 | 350 | 400 | 500 | 600 | 630 | |

| Scraper chain | Pitch(mm) | 100 | 100 | 125 | 125 | 125 | 200 | 200 | 200 | 200 | 200 | 250 | 250 |

| 125 | 125 | 160 | |||||||||||

| Line speedm/s |

0.133 - 0.183 |

0.133 - 0.166 |

0.167 - 0.192 |

0.183 - 0.2 |

0.183 - 0.245 |

0.266-0.3 | 0.275-0.35 | ||||||

| Delivery volume(m3/h) |

6.912 - 9.504 |

15.36 - 19.87 |

19.44 - 22.35 |

13.76 - 25.92 |

33 - 44.1 |

71.82 - 81 |

76.61 - 86.4 |

100.5 - 113.4 |

126.4 - 142.65 |

172.36 - 194.65 |

213.84 - 272.16 |

249.48 - 317.52 |

|

| Conveying distance(m) | 10-50 | ||||||||||||

| Motor(kw) | 2.2-22 | ||||||||||||

| MC, MZ, GSZ.GSL buried scraper conveyor technical parameters Reference table | |||||||||||||

| Model | 12 | 16 | 18 | 20 | 25 | 30 | 32 | 35 | 40 | 50 | 60 | 63 | |

| Slot width(mm) | 120 | 160 | 180 | 200 | 250 | 300 | 320 | 350 | 400 | 500 | 600 | 630 | |

| Scraper chain | Pitch(mm) | 100 | 100 | 125 | 125 | 125 | 200 | 200 | 200 | 200 | 200 | 250 | 250 |

| 125 | 125 | 160 | |||||||||||

| Line speedm/s |

0.1 - 0.183 |

0.133-0.183 |

0.283 - 0.25 |

0.21-0.26 | 0.26-0.306 | 0.25-0.35 | |||||||

| Delivery volume(m3/h) |

3.89 - 5.17 |

9.22 - 12.67 |

10.37 - 14.25 |

12.48 - 17.16 |

33 - 36 |

36.29 - 44.39 |

38.7 - 47.92 |

56.7 - 69.4 |

64.8 - 79.3 |

90 - 110.16 |

118.8 - 166.32 |

124.74 - 174.64 |

|

| Conveying distance(m) | Vertical 20 Horizontal 25 | ||||||||||||

| Motor(kw) | 2.2-22 | ||||||||||||

Scraper Conveyor Conveyor Estimates:

If you do not find the conveying capacity that meets your needs in the parameter table, you can estimate your material conveying capacity according to the following formula. First, you need to select a certain type of Scraper Conveyor:

Q=3600F*V*ɑ*Y*C

Q-transport volume (t/h)

F-Scraper Conveyor loading net section (㎡)

V-chain speed (m/s) There are two kinds of chain speed: 0.48m/s and 0.76m/s

Ɑ-Filling coefficient, generally choose 0.5-0.75, choose the lower limit of density for large particle size materials

Y-transport material density (t/m³)

C-Inclination correction coefficient, when the inclination angle is 0°, the coefficient is 1

If you can't choose the model or you still have other questions, please leave your questions and material information, conveying needs, ask us, we will be happy to help you!

Points to note when selecting Scraper Conveyor:

1. Selection of chain speed: The user should first select the appropriate chain speed according to the state of the material. If the material is highly abrasive, high temperature, has many coarse particles or relatively large particles, choose slow conveying.

2. Model selection: After the chain speed is determined, the most suitable model can be selected according to the conveying capacity. Under the same conveying capacity, choosing a larger model can reduce the conveying speed, thereby prolonging the service life. However, the conveying capacity should not be too small. If the actual conveying capacity is lower than 30% of the rated conveying capacity of the machine, the material layer is too thin during use, which will cause the machine to run idly and increase wear instead.

3. Selection of inlet and outlet: For materials with poor fluidity or high temperature, it is not suitable to use the upper inlet to avoid poor feeding. Due to the limitation of process layout, when the feed inlet is close to the tail axis (the minimum distance cannot be guaranteed), it is generally not suitable to use the upper feed inlet.

Application

Scraper conveyor is not only the transportation of coal and materials, but also the running track of the shearer, so it has become an indispensable main equipment in the modern coal mining process. It can be used for horizontal transportation and also can be used for inclined transportation. When transporting upward along the inclination, the inclination angle of the coal seam shall not exceed 25°, and when transporting downward, the inclination angle shall not exceed 20°. The flexible scraper conveyor is allowed to bend 2°~4° in the horizontal and vertical directions.

Conventional model Scraper Conveyor has the following requirements for the conveyed materials:

1. Material bulk density: y=0.2~1.8t/m3;

2. Material temperature: t<100°C:

3. Moisture content: For general materials, it is not allowed to make the materials not easy to loose after being kneaded by hand; for the increase of water content, the adhesion and compaction will be increased, and the materials should not be seriously adhered to the scraper.

4. Particle size: The particle size of the material is related to its hardness. If the particle size is too large, it is not suitable for conveying. If the product you need to transport is special, please consult the relevant technical personnel.

Solutions by Industry

| Conveying slag | Conveying fly ash | Conveying limestone | conveying coke | |

| Delivery volume | 270 cubic meters per hour | 130 cubic meters per hour | 340 cubic meters per hour | 80 cubic meters per hour |

| Conveying length | 22m | 15m | 25m | 12m |

| Slot width | 500mm | 350mm | 600mm | 270mm |

| model | 500Scraper Conveyor | 350Scraper Conveyor | 600Scraper Conveyor | 270Scraper Conveyor |