Screw Conveyor Blade

Relying on the friction between the screw conveyor blade and the material to push the material forward

Other name: Screw blade, auger flight, auger blade, screw

Material: carbon steel, stainless steel, manganese steel

Thickness: 2.5mm-6mm, 15mm-30mm

Types: with shaft, Non shaft, Continuous, Piece type

Outer diameter: 20-200mm

Inner diameter: 8-60mm

Pitch: 20-200mm

Main Use: Usually, it is used on the screw conveyor and drill equipment.

Introduction of Screw Conveyor Blade

Screw conveyor blade is a component of a screw conveyor system, which is a common type of mechanical conveying system used to transport bulk materials. The screw conveyor blade is a helical flighting that is attached to a central shaft and rotates to move the material along the conveyor.

Screw conveyor blades are typically made from materials such as carbon steel, stainless steel, or other metals that are resistant to wear and corrosion. The design of the screw conveyor blade is critical to its performance, as it affects the rate of material flow, the amount of material that can be transported, and the efficiency of the conveyor system.

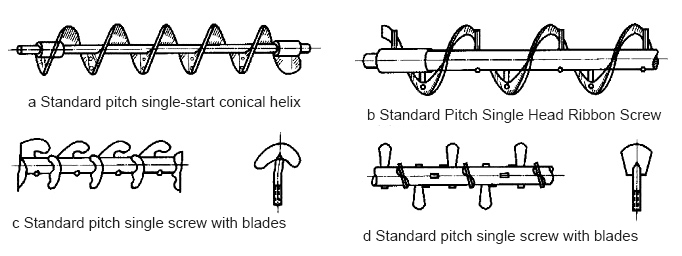

Types of Screw Conveyor Blade

The size, shape and material of the blades of the screw conveyor are also different according to the conveying of different materials. The shape and function of several types of spiral blades are introduced below for users' reference.

Standard pitch single-start conical helix - the diameter of the helical blade gradually increases from 2/3 to the full diameter, which is called a conical helix. For uniformly unloading bulk materials from silos. Compared with the variable pitch screw, its effect is the same but more economical.

Standard Pitch Single Head Ribbon Screw - This screw is generally used to convey viscous, sticky or sticky materials. Since these materials are easy to adhere to the solid surface helical blades and shafts, and there is space between the belt blades and the shaft, the use of such belt blades can prevent materials from sticking and accumulating.

Standard pitch single screw with blades - this type of screw is a combination of a solid face screw and blades. The direction of the paddle is opposite to the direction of the material flow, so that the material can be fully and moderately mixed in the process of moving the material and controlling the flow of the material.

Standard pitch serrated edge single-start helix - regular serrations are cut at equal distances on the outer edge of the helix, so that the material can be moderately agitated during the movement. It is generally used to convey materials that are prone to agglomeration.

Standard pitch single head screw - the pitch of the conveyor screw is equal to the diameter of the screw, which is called the standard pitch. This kind of screw has a wide range of adaptability to materials and is often used.

Variable Pitch Single Head Screw - This progressively increasing pitch screw is used in screw feeders to uniformly discharge powdery, easy-flowing material along the entire length of the inlet.

Material of the Screw Conveyor Blade

Stainless steel material: not easy to rust, acid and alkali resistance, high temperature resistance, low temperature resistance, wear resistance, longer service life.

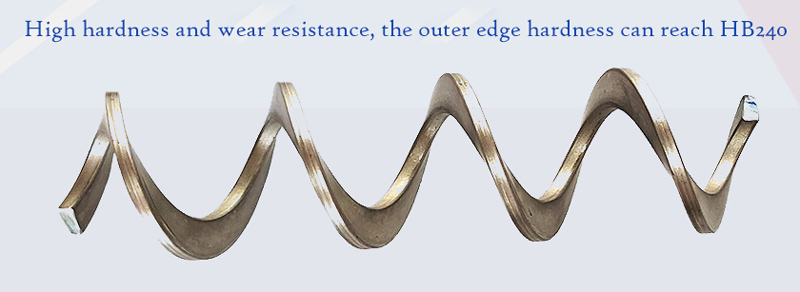

Carbon steel material: The screw conveyor blade has higher hardness and wear resistance, which can ensure its long-term use, but its thermal hardness will be poor, because when the working temperature is greater than 200 ℃, its hardness and Abrasion resistance will drop sharply.

Manganese steel material: high hardness, high strength, better anti-wear performance, suitable for conveying materials with strong grinding, but easy to rust.

Technical Parameters

|

Pitch P (mm) |

Min. ID d (mm) |

Max OD D (mm) |

Ratio of OD and ID |

Min. OD (mm) |

Thickness T (mm) |

| 60-100 | 20 | 480 | 0.25 | Min OD=Pitch customized X ratio | 3-16 |

| 100-150 | 30 | 480 | 0.25 | 3-18 | |

| 150-200 | 50 | 520 | 0.33 | 3-20 | |

| 200-250 | 60 | 630 | 0.3 | 3-25 | |

| 250-300 | 65 | 670 | 0.25 | 3-25 | |

| 300-350 | 90 | 900 | 0.3 | 3-30 | |

| 350-400 | 90 | 950 | 0.25 | 3-30 | |

| 400-450 | 95 | 950 | 0.25 | 3-30 | |

| 450-500 | 135 | 1150 | 0.33 | 3-35 | |

| 500-550 | 150 | 1200 | 0.3 | 3-40 |

Features and Benefits

Screw conveyor blades are key components of screw conveyor systems and play a key role in the efficient conveying of bulk materials. Following are some of the features and benefits of screw conveyor blades:

Feature:

Spiral Blade: Provides a continuous, smooth surface for material flow, reducing the risk of material clogging and ensuring consistent transport.

Customizable Design: Can be customized to meet specific application requirements, including the size and shape of the material being conveyed, the material flow rate, and the distance the material needs to be conveyed.

Material Options: Available in a variety of materials, including carbon steel, stainless steel, and other metals, allowing customization to the specific needs of the application.

Different Blade Types: There are many different types, each with unique features and benefits. This allows for customization to the specific requirements of the material being transported and the application.

Benefit:

Efficient Material Handling: Designed to efficiently handle a wide variety of bulk materials, allowing large volumes to be transported with minimal downtime.

Low Maintenance: Minimal maintenance is required, reducing downtime and increasing productivity.

Contamination Control: Can be engineered to have a smooth surface finish with minimal crevices, making it easy to clean and preventing the build-up of debris or contaminants.

Cost-effective: They are relatively low-maintenance, have a long service life, and can be customized to meet specific application requirements.

Application

The screw conveyor blade is a kind of conveying equipment without flexible parts. It conveys bulk materials in a certain direction through screw blades. The screw conveyor has a simple structure, small cross-sectional area, good sealing performance, flexible process layout, easy chip removal, feeding and unloading at any position, safe and convenient operation and low cost. It is used in machine tools, building materials, chemicals, food and other industries. .

Warehouse by Factory