Screw Conveyor Machine

Used to transport bulk materials from one part of a process to another in a horizontal, inclined or vertical direction.

Screw diameter: 100mm-600mm

Length: 2-20m

Conveying angle: 0-90°

Type: Tube/U-channel

Material: Carbon steel (low cost), stainless steel (easy to clean), plastic (corrosion resistant)

Application: suitable for transporting powdery, granular, flaky and paste materials, such as flour, sawdust, plastic granules, plastic flakes, sludge, etc.

Introduction of Screw Conveyor Machine

Srew conveyor machine uses a rotating spiral screw to transport bulk materials from one point to another. It consists of a rotating spiral blade enclosed in a trough or tube. As the spiral rotates, it pushes the material along the trough, thereby achieving efficient and controllable material transportation. It is suitable for conveying a variety of materials, including powders, granules and pellets.

The srew conveyor machine has two types of U-shaped troughs and circular spiral troughs. It is made of steel plates with a common thickness of 2-10mm or heat-resistant steel plates. If the material temperature is high, steel must be used.

Types of Screw Conveyor Machine

Screw conveyor machines come in various types, each designed to handle specific materials and applications. Here are some of the most common types:

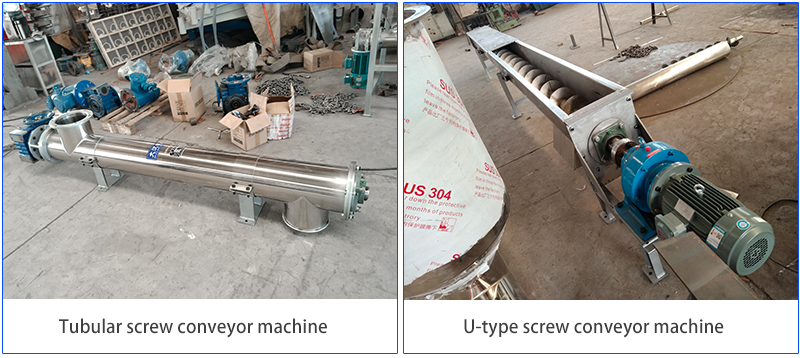

Classification by shape

Tubular screw conveyor machine: It adopts circular pipe, good sealing, prevents material leakage and pollution, is suitable for conveying fine powder, granules and other materials, and is widely used in food and chemical industries. U-type screw conveyor machine: It adopts U-shaped trough design, which is convenient for maintenance and cleaning, and is often used for conveying bulk materials such as grain and ore.

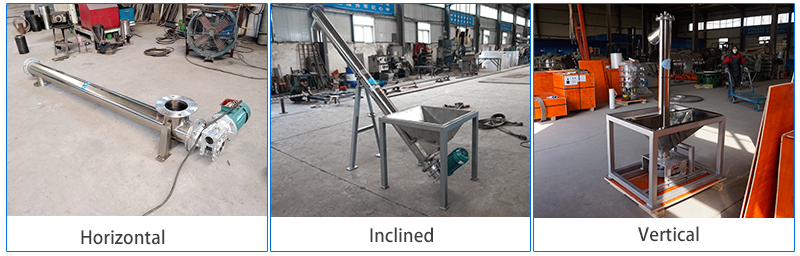

2. Classification by conveying angle

Horizontal screw conveyor machine: The conveying shaft is parallel to the horizontal plane, and multiple feeding and unloading points can be used to effectively distribute bulk materials to various locations. It is suitable for short-distance conveying, with a horizontal length of up to 20 meters, and can be designed to be longer as required.

Inclined screw conveyor machine: The conveying shaft is at a certain angle to the horizontal plane, usually between 15° and 45°, and is used in occasions where vertical or inclined conveying is required, such as grain lifting.

Vertical screw conveyor machine: It is specially designed for material conveying in the vertical direction, and is often used for vertical lifting of powder and granules, such as flour mills.

How Does Screw Conveyor Machine Works?

The screw conveyor machine conveys materials along the axis of the conveyor through a rotating screw. Here is how the screw conveyor works:

Feeding: The material is fed into the spiral groove through the feed port, starting the conveying process.

Screw rotation: The screw inside the conveyor begins to rotate, usually driven by a motor or other power device.

Material transmission: As the screw rotates, the material is pushed forward. The pitch of the spiral groove pushes the material forward according to the design requirements, while the spiral blades fix the material in the spiral groove to prevent the material from flowing back.

Discharging: During the conveying process, the material is gradually transported along the spiral groove of the screw to the discharge port and finally discharged through the discharge port.

Features and Benefits

1.Efficient Material Handling: Screw conveyor machines offer efficient and reliable material handling capabilities, reducing manual labor and streamlining production processes.

2.Versatility: These machines can handle a wide range of materials with varying properties, making them versatile for different industries and applications.

3.Space-Saving: Screw conveyors are compact in design and can be configured to fit into tight spaces, maximizing floor space utilization in industrial settings.

4.Low Maintenance: Screw conveyor machines are known for their low maintenance requirements, providing a cost-effective solution for material handling needs.

Video

Technical parameters

There are many types of screw conveyor machine. If you have special needs, we can customize it according to your needs.

| Mode |

Diameter (mm) |

Rated speed (r/min) |

Reference capacity (m³/h) |

Motor power (Kw) |

Admission biggest gradient (o) |

| LS114 | 114 | 84-130 | 0.1-1 | 2.2-18.5 | ≤60 |

| LS133 | 133 | 1-2 | |||

| LS159 | 159 | 3-5 | |||

| LS219 | 219 | 5-15 | |||

| LS245 | 245 | 15-20 | |||

| LS273 | 273 | 20-30 | |||

| LS315 | 315 | 28-40 | |||

| LS400 | 400 | 35-45 | |||

| LS500 | 500 | 45-70 | |||

| LS600 | 600 | 60-100 |

Difference Between Screw Conveyor Machine And Other Conveyors

| Feature | Screw Conveyor Machine | Belt Conveyor | Bucket Conveyor |

|

|

|

|

| Material Handling | Powders, granules, small objects | Bulk materials, packaged goods | Bulk materials, especially those requiring vertical transport |

| Conveying Direction | Horizontal, inclined, or vertical | Primarily horizontal, with slight inclines | Primarily vertical, with some horizontal sections |

| Conveying Mechanism | Rotating helical screw | Moving belt | Buckets attached to a chain or belt |

| Sealing | Good sealing, minimal material leakage | Less sealing, potential for material spillage | Good sealing, minimal material leakage |

| Maintenance | Moderate maintenance, periodic cleaning and lubrication | Regular maintenance, belt replacement, cleaning | Regular maintenance, chain and bucket replacement, cleaning |

| Capacity | Lower capacity compared to belt conveyors | High capacity, suitable for large-scale operations | Medium capacity, suitable for vertical transport |

| Space Requirement | Compact design, less floor space | Requires more floor space, especially for long distances | Requires more vertical space, especially for high lifts |

| Cost | Lower initial cost | Higher initial cost | Higher initial cost due to complex mechanical components |

| Noise Level | Moderate noise level | Lower noise level | Higher noise level due to mechanical components |

| Energy Consumption | Moderate energy consumption | Moderate to high energy consumption, depending on belt width and speed | Moderate to high energy consumption, depending on lift height and bucket capacity |

Structure of Screw Conveyor Machine

A screw conveyor machine consists of several key components that work together to transport bulk materials. Here is a breakdown of the typical structure of a screw conveyor machine:

Helical Screw Blade: The helical screw blade is the central component of a screw conveyor machine. It is designed with a continuous spiral shape that acts as a conveying surface, pushing materials along the length of the conveyor.

Trough or Tube Enclosure: The screw blade is contained within a trough or tube, which helps to confine the materials being transported. The enclosure prevents spillage and ensures efficient material handling.

Variable Pitch Design: The pitch, or the distance between the threads of the screw blade, can be varied along the length of the conveyor. This allows for controlled material flow and can accommodate different types of materials with varying characteristics.

Inlet and Outlet Ports: Screw conveyor machines have inlet and outlet ports for material loading and discharge. These ports can be customized to suit specific application requirements, such as controlling the flow rate or connecting to other equipment.

Customization

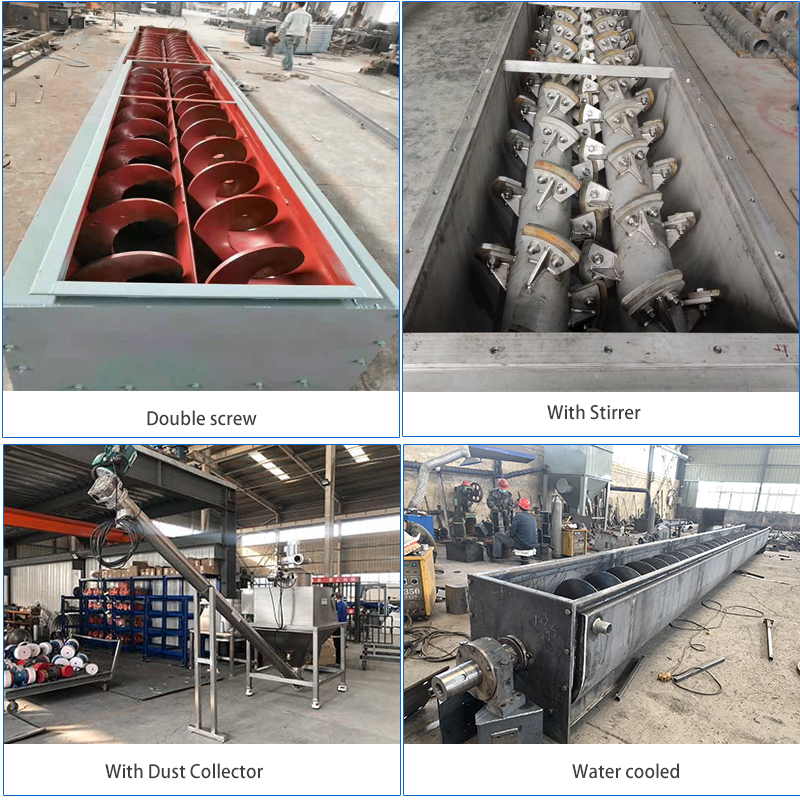

Screw conveyor machine can be customized in many types according to different needs and applications:

Double screw conveyor machine: It has two side-by-side screw bodies, which can improve the conveying capacity and efficiency. It is suitable for occasions where a large amount of materials need to be conveyed, such as large industrial production lines.

Water cooled screw conveyor machine: The material is cooled by a water cooling device during the conveying process. It is suitable for conveying high-temperature materials and is often used to convey high-temperature materials such as cement clinker.

Screw conveyor machine with integrator: The screw conveyor machine with integrator can realize automatic feeding. The integrator can control the feeding speed of the material. It is suitable for occasions where the feeding amount needs to be accurately controlled, such as batching systems or production lines.

Screw conveyor machine with agitator: The screw conveyor machine with agitator can mix or stir the materials during the conveying process to ensure uniformity. It is often used in occasions where different materials need to be mixed or the uniformity of the materials needs to be maintained, such as chemical production or food processing.

When you need to customize the screw conveyor machine, it is recommended that you provide the following information:

Name, density, particle size, temperature, humidity, etc. of the conveying material.

Conveying capacity, conveying distance, conveying height.

Temperature, humidity, corrosiveness, etc. of the working environment.

Special requirements for equipment, such as explosion-proof and anti-corrosion.

Application

Screw conveyor machine is a common material conveying equipment, suitable for various industrial fields and scenarios. The following are some common application scenarios of screw conveyors:

Agricultural field: used to convey agricultural materials such as grains, feed, fertilizers, such as corn, wheat, beans, etc. It can be used in grain harvesting, storage and processing.

Food processing: In the food industry, it can be used to convey powdered or granular raw materials, such as flour, powdered sugar, grains, etc. It can also be used for material conveying in food packaging production lines.

Chemical industry: suitable for conveying chemical raw materials, powders, granules and other materials, such as plastic granules, alumina, sulfur, etc. It is commonly seen in the material conveying process in chemical production lines.

Mining: In the mines and mining industries, it is used to convey materials such as ore, coal, slag, etc. It can be used for material handling and transportation in coal mines and mines.

Building materials: It can be used to convey building materials such as cement, sand, gravel, such as in the raw material supply process of concrete mixing plants.

Water treatment: In sewage treatment plants or water treatment equipment, it is used to convey solid waste or granular materials in the treatment process.

Solutions by Industry

-

Pulverized coal transportation

A power plant needs to transport pulverized coal from storage areas to the combustion system. They chose a customized screw conveyor machine with wear resistance and high temperature resistance to ensure a stable combustion process.

-

Sludge transportation

A wastewater treatment plant needs to transport sludge from settling tanks to sludge treatment equipment. They chose a shaftless screw conveyor machine whose spiral blade design allows handling of high humidity and viscous sludge.

-

Garbage transportation

A waste disposal center needs to transport waste from collection areas to treatment equipment or storage areas. They adopted a screw conveyor machine to handle different types of waste such as solid waste, paper and plastic.

System Solution

As a flexible material conveying equipment, the screw conveyor machine can be matched with a variety of equipment to achieve different process requirements. Common matching methods are as follows:

1. Matching with crushing equipment: Continuously convey the crushed material to the next process, such as packaging, mixing, etc.

2. Matching with screening equipment: Convey the screened material in grades, or convey the screened material and the screened material separately.

3. Matching with mixing equipment: Convey the mixed material to the packaging machine or storage bin.

4. Matching with packaging equipment: Continuously convey the material to the packaging machine for packaging.

5. Matching with lifting equipment: Lift the material to a high place to achieve multi-layer conveying.

6. Matching with conveyor belt: Transfer the material from the screw conveyor to the conveyor belt to achieve long-distance conveying.

7. Matching with storage equipment: Convey the material to the storage tank for storage.