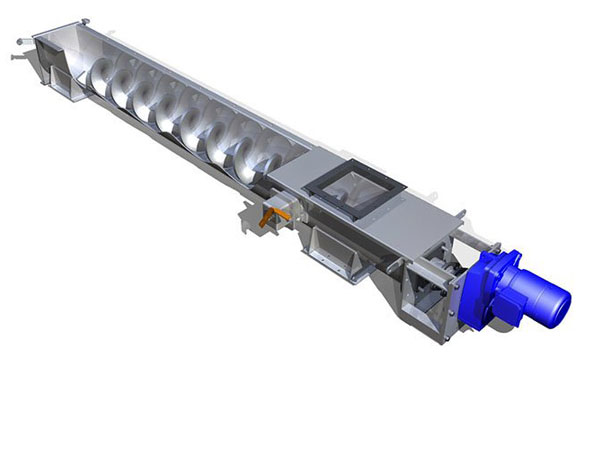

shaftless screw conveyor

The shaftless screw eliminates the clogging and buildup common in shafted screw conveyors and is designed to handle difficult and heterogeneous materials such as municipal solid waste, screenings and floating materials.

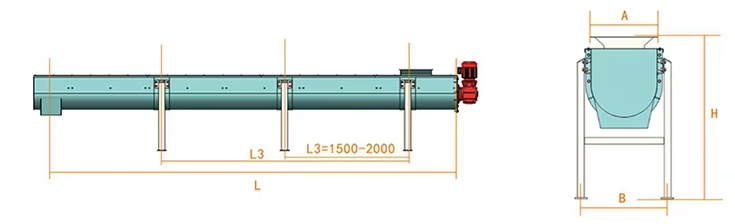

Length: 1-20 meters (customizable length)

Transport capacity: 0.8 mc/h- 45 mc/h

Tilt angle: within 30 degrees

Application: Suitable for conveying sludge, mud cake, pulp, kitchen waste, domestic waste, etc. in industries such as wastewater treatment, solid waste treatment, pulp and papermaking, and garbage disposal.

Introduction of Shaftless Screw Conveyor

The shaftless screw conveyor adopts a shaftless design. Unlike traditional screw conveyors, it can operate without a central shaft, so it can convey a variety of materials, such as sludge, bulk solids and various wastes. Its design reduces the risk of material blockage and obstruction, making it particularly suitable for wastewater treatment, solid waste management and other industries that require reliable and efficient long-distance material transportation.

Due to the lack of an intermediate shaft, all forces are on the blades, so the blades are required to have sufficient strength and rigidity. The thickness of the Dahan shaftless screw conveyor blade is not less than 20mm, which can greatly extend the service life.

Types of Shaftless Screw Conveyors

Single shaftless screw conveyor: Only one spiral blade is suitable for occasions with low mixing requirements and small material particles, such as food and pharmaceutical industries, and low maintenance costs.

Double shaftless screw conveyor: There are two or more spiral blades in opposite directions. The design of double spiral blades can enhance the tumbling and mixing effects of materials, especially suitable for materials that need to be mixed or stirred. The conveying capacity is generally stronger than that of single screw conveyors, and larger particles or viscous materials can be conveyed.

In addition, shaftless screw conveyors are also divided into carbon steel and stainless steel. If the conveyed material is corrosive or has high hygiene requirements, it is recommended to choose stainless steel. If the conveyed material is non-corrosive and has low hygiene requirements, carbon steel can be selected.

Application

Shaftless screw conveyors are widely used in various industries, especially in the following fields:

Sewage treatment: used to transport sludge, wastewater, waste, etc., and plays a key role in sewage treatment plants.

Solid waste treatment: in garbage treatment plants and waste recycling centers, it is used to transport garbage and waste materials to improve processing efficiency.

Food processing: in the food industry, shaftless screw conveyors can be used to transport powdered or blocky food raw materials, such as flour, grain, etc.

Building materials: in the construction industry, it can be used to transport building materials such as cement, sand, and gravel to help the concrete production process.

Video

Features and Benefits

1. The conveyed materials will not be tangled or stuck: because there is no intermediate bearing, it has special advantages for conveying belt-like, viscous materials, and easily entangled materials, which can avoid material blockage.

2. Large conveying capacity: The conveying length of a single machine can reach 60 meters, and the conveying capacity is 1.5 times that of the traditional shaft screw conveyor of the same diameter.

3. Sealed and pollution-free: the tank cover of the gasket ensures that the tank body and the tank cover are sealed to avoid material leakage, no odor leakage, and prevent any gas medium from entering the production system, ensuring the sanitation of the conveying environment.

4. Not easy to damage: the thickness of the screw blade of the shaftless screw conveyor is more than 20mm, and the width of the blade is not less than 80mm, which is more wear-resistant and difficult to be twisted.

5. Flexible layout: single-point or multi-point feeding can be achieved, which can realize the effect of discharging from the bottom and discharging from the end.

Technical parameters

The shaftless screw conveyors produced by Dahan Company are available in various models, and we can also customize them according to your needs.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

Shafted VS Shaftless Screw Conveyor

| Comparison Items | Shafted screw conveyor | Shaftless screw conveyor |

| Center shaft | Yes | None |

| Structure | Relatively simple | Relatively complex |

| Wear resistance | The center shaft is easy to wear, which affects the life of the equipment | No central shaft, wear mainly occurs at the contact surface between the spiral blade and the inner wall of the casing, and blade replacement is relatively easy |

| Sanitation | Poor, materials are easy to accumulate at the center shaft, and cleaning is difficult | Good, easy to clean |

| Adaptability | Weak, poor adaptability to materials | Strong, can convey a variety of materials |

| Main applications | Usually used to transport dry and relatively uniform materials, suitable for general material transportation, such as grain, feed, fly ash, etc. | Suitable for conveying wet, high-water content, paste-like, and ribbon-like products, such as sludge, mud, pulp, and plastic film |

Structure of Shaftless Screw Conveyor

Shaftless screw conveyor consists of shaftless screw blade, U-shaped helical groove, cover plate, lining plate, inlet/outlet port, discharge port and driving device.

Driving device: It is placed at one end of the screw conveyor. It adopts the form of direct connection between the motor reducer and the screw drive shaft. No coupling is required. It is easy to disassemble and maintain. The drive shaft can bear the load of bending distance and axial extrusion force at the same time.

Shaftless Spiral: The material is stainless steel or carbon steel.

Cover: Removable, easy to observe the material conveying condition and later machine maintenance.

Tank liner: The material is wear-resistant molecular polyethylene or 16 manganese, etc.

Inlet and outlet: There are two kinds of square and round. Generally, the form of inlet and outlet is determined by the user.

Industry Solutions

1、garbage collection

Shaftless Screw Conveyor has a good effect when conveying sticky, clumping, clogging domestic waste, industrial waste or kitchen waste, without worrying about the entanglement and clogging of ribbon or cotton waste.

2. Sewage treatment

Shaftless Screw Conveyor is the best choice for conveying viscous dewatered sludge. The design without a central shaft can avoid sludge clogging, and the thickened screw design will not twist the screw due to excessive conveying resistance.

3. Paper slurry

Strictly speaking, the papermaking slurry contains many fibers and is highly viscous, which is easy to adhere to the pipe wall of the conveyor. The Shaftless Screw Conveyor has a removable groove cover, which can be easily disassembled for machine cleaning, and the pipe groove is designed without a central axis. The inner space is larger, and it is not easy to be blocked.

Layout of Shaftless Screw Conveyor

The arrangement of the shaftless screw conveyor is generally horizontal, or it can be inclined, but the inclination angle is generally not more than 25°.

Installation method: The company can provide hanging type; ground and hanging mixed type; mobile type, rotary type and turret type that can be rotated around the axis of the feed inlet.

Customer Cases

-

Sewage treatment plant

A city sewage treatment plant needs to transport sludge to the dewatering machine. By selecting a shaftless screw conveyor made of stainless steel, it is corrosion-resistant, wear-resistant, and shaftless to prevent sludge clogging.

-

Catering company

A large catering company needs to transport food waste to a garbage disposal station. It selects a food-grade stainless steel shaftless screw conveyor to reduce the adhesion of food waste and is easy to clean.

-

Paper mill

A paper mill needs a device that can transport high-concentration pulp, and requires a smooth conveying process without damaging the pulp fibers. The spiral blades are designed with a shaftless design to reduce fiber damage.