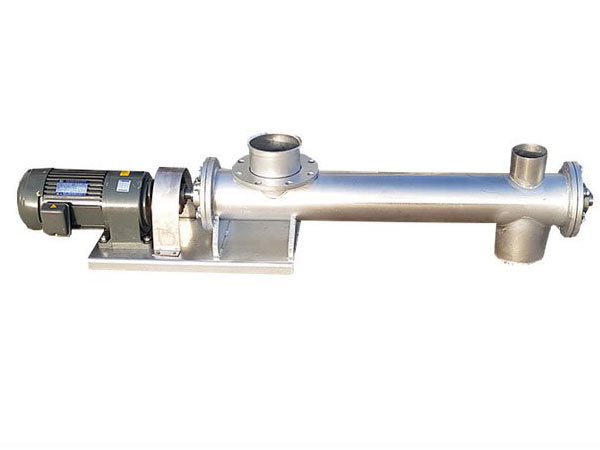

Small Auger Feeder

Uniform and continuous feeding of small batches of powdery and granular materials

Spiral diameter: 114mm-160mm

Length: 100mm-2000mm

Feeding rate: .01kg/hour—1000kg/hour

It is used to quantitatively and continuously feed fine powder and ultra-fine powder from the storage bin or hopper to the receiving device.

Introduction of Small Auger Feeder

Small auger feeder is usually used in the production process of fine powder and ultra-fine powder. The fine powder and ultra-fine powder are quantitatively and continuously fed from the storage bin or funnel to the receiving device. Micro screw feeder It is suitable for easy flow, no cohesion or small cohesion, no abrasiveness or less abrasiveness. The micro screw feeder is not afraid of breaking and requires sealing. The feeding of the micro screw feeder is continuous, uniform and accurate. .

The specifications of the Small auger feeder are determined according to the feeding amount (feeding amount) per hour: the general feeding amount is from 0.01 kg/hour to 1000 kg/hour, and the length of the conveyor (center distance between the inlet and outlet) is generally in 100mm-2000mm, the discharge method is divided into two types: vertical discharge and horizontal discharge. Users can freely choose according to their requirements.

Features and Benefits

1. The whole machine is small in size, compact in size and occupies a small area.

2. The pipe diameter is 114mm, 159mm, 160mm, etc., the conveying length can reach 20 meters, and the conveying capacity per hour can reach 9 cubic meters per hour.

3. It is usually connected under the large feeding equipment to control the feeding flow, and carry out a small amount of uniform and continuous feeding.

4. The whole feeder may be made of stainless steel, which is resistant to acid and alkali corrosion, not easy to rust, and clean and hygienic.

Structure of the Small Auger Feeder

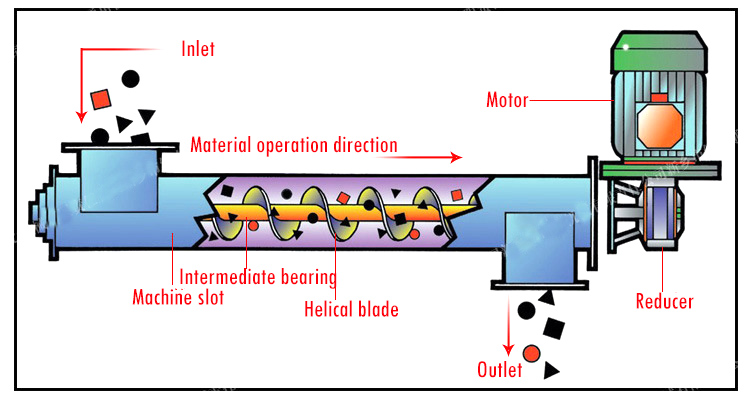

Small auger feeder consists of head bearing, tail bearing, suspension bearing, screw, casing, cover plate and base. The drive device consists of a motor, a reducer, a coupling and a base.

Drive device: including motor, reducer, coupling. The motor is responsible for driving. The reducer prevents the screw shaft from rotating too fast and causing damage to the conveyor. The coupling is responsible for transmitting the power to the screw shaft.

Spiral shaft: It is twisted into a spiral shape by narrow and long steel plates of a certain thickness, and shaft or shaftless design can be selected (shaftless design is more suitable for conveying materials with high water content, sludge, strips, etc., which are easy to wind and attach).

Chassis: A circular sealing tube is used to feed the sealing equipment.

Feeding and discharging device: It is divided into four types: feed inlet, square outlet, hand-push outlet, and rack outlet, which can be selected according to the conditions of the feeding equipment.

Technical Parameters

| LS Type | 100 | 160 | 200 | 250 | 315 |

| GX Type | 200 | 250 | 300 | ||

| Spiral diameter(mm) | 100 | 160 | 200 | 250 | 315 |

| pitch(mm) | 100 | 160 | 200 | 250 | 315 |

| Rotating speed(r/min) | 140 | 120 | 90 | 90 | 75 |

| Delivery volume QΦ=0.33(m3/h) | 2.2 | 7.6 | 11 | 22 | 36.4 |

| power Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 |

| power Pd 1=30m(KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 |

| Rotating speed(r/min) | 120 | 90 | 75 | 75 | 60 |

| Delivery volume QΦ=0.33(m3/h) | 1.9 | 5.7 | 18 | 18 | 29.1 |

| power Pd 1=10m(KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 |

| power Pd 1=30m(KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 |

| Rotating speed(r/min) | 90 | 75 | 60 | 60 | 45 |

| Delivery volume QΦ=0.33(m3/h) | 1.4 | 4.8 | 15 | 15 | 21.8 |

| power Pd 1=10m(KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 |

| power Pd 1=30m(KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 |

| Rotating speed(r/min) | 75 | 60 | 45 | 45 | 35 |

| Delivery volume QΦ=0.33(m3/h) | 1.2 | 3.8 | 11 | 11 | 17 |

| power Pd 1=10m(KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 |

| power Pd 1=30m(KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 |

The small auger feeder produced by Dahan Company are available in various models, and we can also customize them according to your needs.

Video

Application

Small auger feeder is specially designed for users and laboratory applications with small output. It is used in the production process of fine powder and ultra-fine powder. The fine powder and ultra-fine powder are quantitatively and It is continuously fed to the receiving device.

Solutions by Industry

The most common way to use Small Auger Feeder is to add sewage flocculants, which can add a small amount of additives continuously and uniformly, providing a good solution for sewage treatment.

Small Auger Feeder can also be used in pharmaceuticals. The Small screw conveyor made of 316L can accurately feed materials at a speed as low as 32 g/h, ensuring the safety and precision of pharmaceutical production.

In addition, the Small Auger Feeder is also a good choice in the laboratory or classroom teaching due to its small size and low weight.