Small Screw Conveyor

For uniform continuous feeding and discharging of small batches of powdery materials, typically used in the production of chemicals and pharmaceuticals or any process that requires precise small quantities of additives

Diameter: 114mm, 159mm, 160mm, 250mm, 315mm

Conveying capacity: 3-37 cubic meters per hour

Conveying length: 5-60 meters

-

Introduction of Small Screw Conveyor

Small screw conveyors are usually used in the production process of fine powder and ultra-fine powder. The fine powder and ultra-fine powder are quantitatively and continuously fed from the storage bin or hopper to the receiving device, the propeller and the feeding pipe. The minimum gap between ensures high-precision feeding.

The specifications of the small screw conveyor are determined according to the feeding amount per hour (feeding amount): the general feeding amount is from 0.5 kg/hour to 1000 kg/hour (please choose our other screw feeders for more than 1000 kg/hour) feeder). The length of the feeder (center distance between the inlet and outlet) is generally 200mm-2000mm. Discharge method: There are two types of vertical discharge and top discharge. Users can freely choose according to their requirements.

Technical Parameters

| Model | 100 | 160 | 200 | 250 | 315 | 400 |

|

Screw diameter (mm) |

100 | 160 | 200 | 250 | 315 | 400 |

|

Screw pitch (mm) |

100 | 160 | 200 | 250 | 315 | 355 |

|

Rotating speed (r/min) |

100 | 120 | 90 | 90 | 75 | 75 |

|

Capacity Qφ=0.33 (m3/h) |

2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 |

|

Power Pd 1=10m (kw) |

1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 |

|

Specification only for your reference, size variable as per customer's request. Note: Please use other types of screw conveyors of our company for those larger than 1000 kg/h. |

||||||

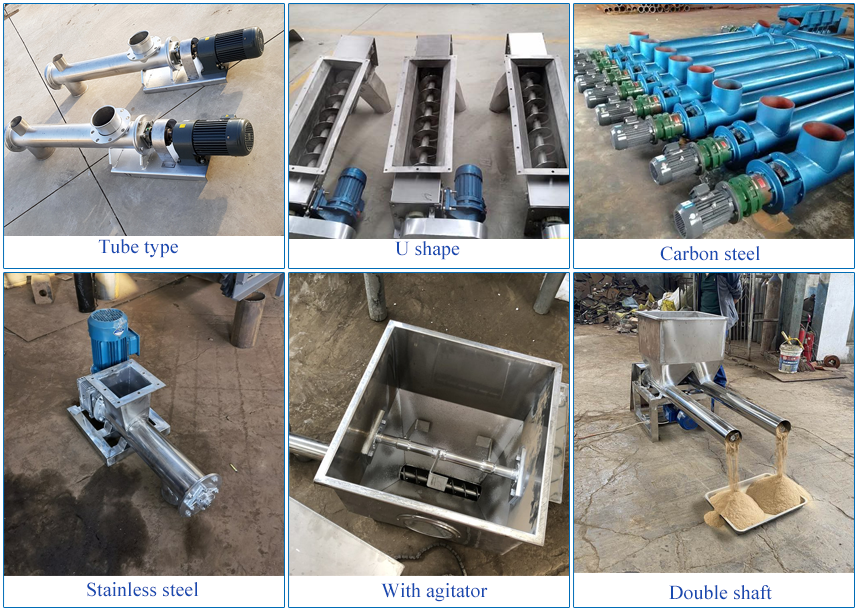

The various types of small screw conveyors produced by Dahan Company are available. If you have special needs, we will design them free of charge according to your actual situation.

Features and Benefits

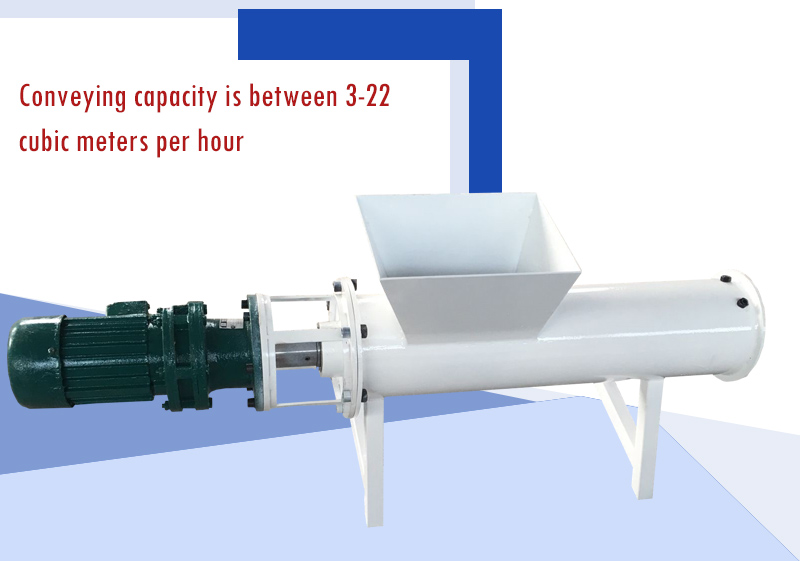

1. The conveying capacity is between 3-22 cubic meters per hour, which is suitable for continuous feeding of small batches of powdery materials.

2. Small diameter and fast rotation speed can ensure uniform transportation of materials, and materials are not easy to be blocked. A loading and unloading gate can also be installed to control the flow of materials.

3. During the conveying process, the materials can be stirred, mixed, heated and cooled.

4. The whole conveying work is carried out in the pipeline, which avoids the pollution of dust to the environment and improves the working conditions at the same time.

5. It can be installed horizontally, can also be adapted to angular working conditions, and can even be transported vertically, instead of hoists to save production costs.

Types of Small Screw Conveyor

Video

Application

Small screw conveyor is used for uniform and continuous feeding and unloading of small batches of powdery materials. It is usually used in the production process of fine powder and ultrafine powder to quantify fine powder or ultrafine powder from storage bins or hoppers. It is continuously fed to the receiving device.

Dosing range: 0-100g/h, 100-1000g/h, 1-5Kg/h, 5-10Kg/h, 10-30Kg/h, 100-1000Kg/h.

Solutions by Industry