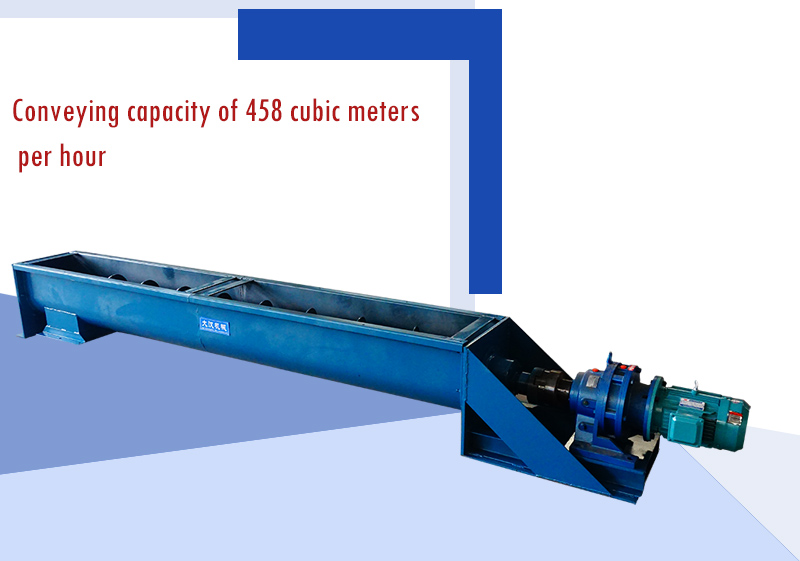

Spiral Auger Conveyor

The material is pushed by the rotating helical blade

Spiral Diameter: 100mm-1250mm

Conveying capacity: 458 cubic meters per hour

Conveying length: 70 meters

Spiral auger conveyor can convey powder, granular and small block materials horizontally, inclined or vertically

Introduction of Spiral Auger Conveyor

Spiral auger conveyor is the use of rotating spiral blades to push the material for conveying, mainly used for horizontal conveying, inclined conveying, vertical conveying of granular or powdery materials, etc. The conveying distance varies according to the shape of the machine, generally from 2 meters to 70 meters Meter.

Spiral auger conveyors are versatile and offer a variety of standard solutions for the handling of powdered or granular materials. Different models of conveyors or feeders are available for concrete production (fly ash, filler dust, silica fume), premixed building materials (dry plaster, sand, cement, additives), glass processing (calcium carbonate, soda, sand ), etc.), foundries (sand, bentonite), etc.

Different Types of Spiral Auger Conveyor

1、Position - horizontal or inclined or vertical

Horizontal spiral auger conveyor:The most widely used conveyor type, horizontal screw conveyors move material depending on its characteristics at a range of 15–45% trough loading.

Inclined spiral auger conveyor:ypically operating at angles between 0° and 45°, inclined screw conveyors transport and elevate material through different levels of your facility.However, note that increasing the incline degree increases friction loss, thus reducing conveyor efficiency.

Vertical spiral auger conveyor: It conveys materials vertically upward at 90° to the ground, which saves a lot of space and space compared to other screw conveyors. It is suitable for conveying powder and granular materials with good fluidity. It is mainly used for lifting materials, and the lifting height is generally not more than 8 meters. .

2、Type of spiral – With or without a center core

Shafted spiral auger conveyor: A central shaft is added to the helical blade, which can help the conveyor improve efficiency and prevent material accumulation and slipping. Such a central shaft design is also the design of most conventional screw conveyors, and is suitable for a variety of bulk powder and granular materials that are easy to convey (such as flour, coal ash, etc.).

Shaftless spiral auger conveyor: Compared with the traditional shafted screw conveyor, it adopts a design without a central shaft, and uses a certain flexible integral steel screw to push materials without central shaft interference. the superiority. It is more suitable for conveying viscous and easily entangled materials (such as kitchen waste, sludge, etc.).

Features and Benefits

1. Because the conveying process of the spiral auger conveyor is based on the internal friction of the material, it changes the pushing of the material into pulling, which saves 50% of electricity compared with the belt conveyor.

2. The conveying capacity is large, allowing a large amount of materials to be conveyed in a small space, with a conveying capacity of 458 cubic meters per hour.

3. It can realize sealed transportation, which is conducive to the transportation of easy-to-fly, hot and strong-smelling materials, which can reduce environmental pollution and improve the working conditions of port workers.

4. It is convenient to load and unload, and can be loaded and unloaded at any point on its conveying line; the configuration of the vertical screw conveyor can have excellent reclaiming performance compared to the screw reclaiming device.

5. Flexible layout, can be arranged on elevated, ground or pit, can be installed horizontally or on a slope (≤15°), or can be installed horizontally and on a slope with the same machine, and can be loaded and unloaded at multiple points.

6. It can be conveyed in the reverse direction, and one conveyor can also convey materials in two directions at the same time, that is, to the center or away from the center.

Structure of Spiral Auger Conveyor

Spiral auger conveyor is composed of a series of components such as drive equipment, head end accessories, body, screw shaft, inlet and outlet.

Driving equipment: Two kinds of driving equipment, cycloidal pinwheel reducer or hardened gear reducer, are selected. In the design, the driving equipment is installed at the discharge port end as much as possible, so that the entire helix is in a receiving state when it rotates. pull condition.

The head end of the auger screw conveyor is equipped with a thrust bearing, which can withstand the axial force generated when transporting materials.

Body: This is generally U-shaped or O-shaped. The upper part of the body is generally equipped with a rain-proof cover. The raw materials of the body are generally stainless steel, carbon steel, and glass fiber reinforced plastic.

Spiral shaft: The raw materials are stainless steel and carbon steel. According to the characteristics of the conveyed material, there are two kinds of shafts and no shafts.

Material inlet and outlet: There are square and round shapes in this shape, which can also be selected by the user.

Technical Parameters

| LS Type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX Type | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter(mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| pitch(mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Rotating speed(r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Delivery volume QΦ=0.33(m3/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| power Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| power Pd 1=30m(KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Rotating speed(r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Delivery volume QΦ=0.33(m3/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| power Pd 1=10m(KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| power Pd 1=30m(KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Rotating speed(r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Delivery volume QΦ=0.33(m3/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| power Pd 1=10m(KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| power Pd 1=30m(KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Rotating speed(r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Delivery volume QΦ=0.33(m3/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| power Pd 1=10m(KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| power Pd 1=30m(KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

The various types of spiral auger conveyors produced by Dahan Company are available. If you have special needs, we will design them free of charge according to your actual situation.

Application

Spiral auger conveyor is mainly used in sewage treatment plants, garbage recycling plants, sand yards, sand washing production lines, coal-fired boilers and other occasions to transport powder, granular and small block materials, such as cement, fly ash, sludge , garbage, silt, fertilizer, mineral powder, sand, soda ash, etc.

Solutions by Industry