Tube Screw Conveyor

Uses rotating spiral blades within a tubular housing to transport bulk materials, including powders, granules and flakes. The tubular design reduces dust emissions.

Diameter: 113-600mm

Rated speed: 84-130 r/min

Capacity: 0.1-100m³/h

Angle: 0-90 degrees

Application: Used in industries that require horizontal, inclined or vertical movement of materials, such as food, feed, chemical, grain, concrete, etc.

Tube screw conveyor is also called tubular screw conveyor, which can convey powder or granular materials horizontally, inclined and vertically. It is a continuous conveying equipment that uses spiral rotation to move materials. Different types of conveyors or feeders can be used for concrete production (fly ash, filler dust, silica fume), premixed building materials (dry plaster, sand, cement , additives), glass processing (calcium carbonate, soda, sand, etc.), foundries (sand, bentonite), etc.

The screw diameter of the tubular screw conveyor is 100-1250mm, the speed is fast, the material is not jammed, the material is not arched, and the material is discharged smoothly. Because the conveying process is carried out in a closed pipeline, there is basically no dust pollution, and the conveyed material will not leak. Improved work environment.

Finished Product Display

Types of Tube Screw Conveyor

There are various types of tube screw conveyors available, each designed to meet specific application requirements. Here are some common types:

1.Horizontal Tube Screw Conveyor: This is the most basic type of tube screw conveyor, where the tube is horizontal, and the screw rotates to move material along the length of the conveyor. It is suitable for horizontal conveying of bulk materials over short to medium distances.

2.Inclined Tube Screw Conveyor: In this type, the tube is inclined at an angle, allowing for vertical or inclined conveying of materials. Inclined tube screw conveyors are used when there is a need to transport materials between different levels or when a specific elevation angle is required.

3.Vertical Tube Screw Conveyor: Also known as an elevator conveyor, a vertical tube screw conveyor is used for lifting bulk materials vertically. It is commonly used for applications where materials need to be elevated to a higher level, such as transferring materials to silos or storage bins.

How does a tube screw conveyor work?

Material Intake: The material to be transported is fed into the inlet of the tube screw conveyor.

Rotation of the Screw: The helical screw blade, also known as an auger, rotates inside the tube. This rotation creates a pushing or pulling action, depending on the design, which moves the material along the length of the tube.

Material Transport: As the screw rotates, it carries the material along the tube. The design of the screw blade helps in effectively moving different types of materials, such as powders, granules, or small pellets.

Discharge: The material reaches the discharge end of the conveyor, where it can be directed to the next stage of the process, a storage container, or another destination.

Advantages of Tube Screw Conveyor

1. Closed design: The tubular design minimizes dust emissions and protects materials from contamination and external factors.

2. Versatility: Suitable for transporting a variety of materials, including bulk powders, grains and granules, suitable for horizontal, inclined or vertical conveying, and can meet the conveying needs in different industrial scenarios.

3. High space utilization: The compact design can save space and is suitable for factories or production lines with limited space.

4. Flexibility: The tubular design can adapt to different conveying angles and paths, providing flexibility and diversity, and can be customized according to needs.

Video

Technical parameters

| Model |

Diameter (mm) |

Rated speed (r/min) |

Reference capacity (m³/h) |

Motor power (Kw) |

Admission biggest gradient (o) |

| LS114 | 114 | 84-130 | 0.1-1 | 2.2-18.5 | 0-90 degrees |

| LS133 | 133 | 1-2 | |||

| LS159 | 159 | 3-5 | |||

| LS219 | 219 | 5-15 | |||

| LS245 | 245 | 15-20 | |||

| LS273 | 273 | 20-30 | |||

| LS315 | 315 | 28-40 | |||

| LS400 | 400 | 35-45 | |||

| LS500 | 500 | 45-70 | |||

| LS600 | 600 | 60-100 |

Customization

Tube screw conveyors can be customized according to different application requirements and material characteristics to meet specific conveying requirements.

1. Cooling type: It is used to quickly cool high-temperature materials. It adopts a unique water cooling system. By setting a jacket on the outside of the barrel or the screw shaft and the conveying pipeline, cooling water circulates in the jacket. The cooling water absorbs the heat generated by the material during the conveying process, which reduces the material temperature. It not only realizes the material conveying, but also effectively reduces the material temperature.

2. Stirring type: The screw conveyor combined with the stirring function is equipped with a stirring device (feeder) at the feed inlet, which is used to crush the damp and agglomerated products before conveying. It is commonly used in food processing and chemical production.

3. Anti-corrosion type: It is made of corrosion-resistant plastic material (polypropylene), which can resist chemical corrosion and is suitable for conveying corrosive materials.

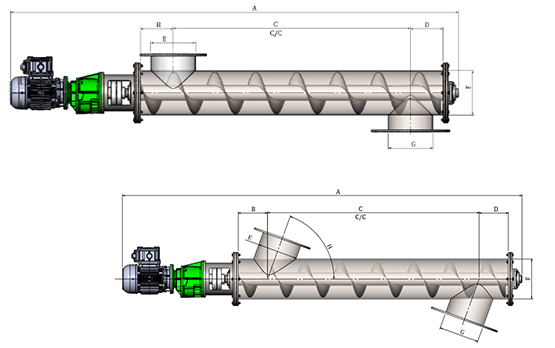

Structure of Tube Screw Conveyor

Tube screw conveyor generally consists of three parts: conveyor body, inlet and outlet and drive device. The spiral body is composed of three parts: the head section, the middle section and the tail section.

Driving device: Q series reducer + Y series motor, YTC gear reducer motor.

Feeding and discharging device: There are four kinds of feeding port, square discharging port, hand-push discharging port and rack-type discharging port. It is welded on the body by the user at the site of use. When arranging the positions of the inlet and outlet ports, attention should be paid to ensure the distance from the material port to the end, and at the same time, avoid the material port from colliding with the hanging bearing refueling cup, the casing connection flange, the base, etc.

Screw machine body: A thrust bearing is installed in the head section to bear the axial force, and a bearing is installed in the middle section and the tail section to support the screw shaft. At the same time, there are axially movable radial bearings in the tail section of the screw conveyor to compensate for the error of the length of the screw shaft and adapt to temperature changes.

Optional for Tube Screw Conveyor

| Accessories display | Accessory name | Application advantages |

|

Universal wheel | Make Tube Screw Conveyor move freely and quickly arrange |

|

feed bin | With the feeding device, uniform and automatic feeding |

|

Multiple inlet and outlet ports | Multi-point feeding and discharging, with on-site production conditions, can mix and stir a variety of bulk materials |

|

Explosion-proof motors | Higher safety, used when transporting dangerous and explosive materials |

|

Dual Motor Design | The screw pulling force is stronger, and the Tube Screw Conveyor above 35 meters chooses two motors to convey at the same frequency to ensure sufficient conveying power |

| The table is only an example of some special design situations. The specific design is subject to your conveying materials and site conditions. For more information, please consult the manufacturer. | ||

Application

Tube screw conveyor is widely used in various industries. The following are common application scenarios in common occasions:

Grain processing plants: conveying grains, flour, cereals, etc., helping to transport raw materials from storage areas to different workstations on the processing line.

Food production lines: conveying food raw materials, such as powdered sugar, starch, spices, etc., and conveying packaging boxes or containers.

Feed mills: conveying feed raw materials, such as granular feed, additives, etc., and conveying mixed feed to packaging or storage areas.

Cement plants: used to convey raw materials such as cement, limestone, coal, and convey mixed cement to mixing plants or different processes on production lines.

Concrete mixing plants: conveying concrete raw materials, such as cement, sand, aggregates, etc., and conveying concrete from mixers to discharge ports or transport vehicles.

Chemical production lines: conveying chemical raw materials, granular products or powders, and playing a key role in the material conveying and processing process on production lines.

Solutions by Industry

-

Conveying fly ash

A power plant uses Tube screw conveyor to transport fly ash. Fly ash is a by-product of the power generation process and needs to be handled and transported efficiently. Tube screw conveyor transports fly ash from the collection system of the power plant to the storage or processing area by pushing it with a screw.

-

Conveying sawdust

A wood processing plant uses a Tube screw conveyor to transport wood chips. During wood processing, large amounts of wood chips are produced, which need to be handled and transported. The Tube screw conveyor transports wood chips from the production line to the storage area or other processing equipment through spiral rotation.

-

Conveying sand

A construction company uses a Tube screw conveyor to transport sand. On construction sites, large quantities of sand need to be transported from one site to another for use in concrete preparation or other construction processes. The Tube screw conveyor transports sand from the storage area or supply area to the required construction location through screw pushing.

How to Choose Tube Screw Conveyor?

Tube screw conveyor customers provide the following parameters before purchasing

Our manufacturer selects and designs based on the parameters you provide. We have 15 years of experience in design and production, and our products are of good quality.

1. If you are replacing, you need to provide the flange type (round or square), flange (outer diameter, inner diameter, flange hole distance), inlet and outlet distance. If it is a new installation, you can ignore these parameters. When you install Just make it according to our size.

2. You need to provide some parameters such as installation conditions, material name, material particle size, whether the material has hardness, whether the material has viscosity, material temperature, import and export distance, the conveying volume you need, etc. We will help you make a reasonable selection. You need it, and we guarantee that you can use it comfortably and rest assured.