Twin Screw Conveyor

Consists of two helical shafts with opposite directions of rotation. It has the functions of conveying, mixing and stirring. For conveying loose, difficult to convey, difficult to flow powdery, fibrous or granular materials.

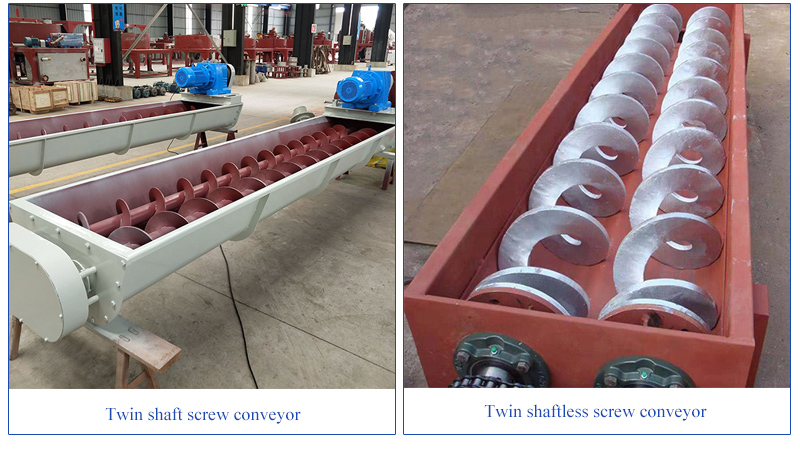

Type: double shaft / double shaftless

Conveying capacity: 134m³/h

Length: ≤20 meters

Application: For free-flowing powders and fine particles, but they are ideal for feeding difficult materials such as heterogeneous materials (wood chips, paper, etc.), materials in the flour processing industry (bran, flour, etc.) and bridging materials (eg sawdust, soybeans, etc.).

Twin screw conveyor is a conveyor system that uses two parallel screws or augers to move material. The screws are usually mounted side by side in troughs or housings and rotate in opposite directions to move material along the conveyor. Compared to single shaft screw conveyors, twin screw conveyors can handle higher volumes of material and can provide a higher degree of mixing and blending. The counter-rotation of the screws also helps prevent material from getting stuck or clogging inside the conveyor.

The Twin screw conveyor is mainly suitable for feeding under silos, usually working in horizontal direction, for handling heterogeneous materials (wood chips, paper, etc.), materials in the flour milling industry (bran, flour, etc.) and bridging materials (eg sawdust, soybeans, etc.).

Types of Twin Screw Conveyor

Twin shaft screw conveyor: It can convey not sticky, and has a certain friction, which has certain requirements on the wear resistance of the screw conveyor.

Twin shaftless screw conveyor: It can transport granular/powder/wet/paste, semi-flow pattern/viscous materials that are easy to entangle and block, such as sludge, etc. It is also suitable for materials with special hygiene requirements.

Stainless Steel Twin Screw Conveyor:

304 or 316L material, high hygiene standards, corrosion and wear resistance, commonly used in food, medical or chemical, abrasive and other industries.

Carbon Steel Painted Twin Screw Conveyor:

The movable gripper design can clamp the side wall of the truck and realize the transportation of grain from low to high without other arrangements.

Function of Twin Screw Conveyor

The primary function of a twin screw conveyor is to move material from one location to another in a controlled and efficient manner. Here are some specific features of twin screw conveyors:

1. Conveying: It is mainly used in the industry of conveying powdery and small-diameter particles. It generally operates in a horizontal direction and is suitable for feeding under the silo.

2. Mixing: It can be used for mixing when the material is transported along the conveyor. This is achieved by designing the screws with different pitches and speeds, creating a shearing action that mixes the materials together.

3. Cooling or heating: Double screw conveyors can be equipped with heating or cooling jackets to control the temperature of the conveyed materials. This is especially useful in applications where materials need to be cooled or heated during transport.

4. Crushing or grinding: Twin screw conveyors can be designed with special features, such as teeth or paddles, to break or grind material as it travels along the conveyor.

Features and Benefits

1. Double shaft design, the material can be cooled, loosened, mixed and stirred during the conveying process.

2. Generally used for horizontal short-distance transportation, the conveying length is generally less than 40 meters, and the vertical conveying height is generally not more than 8 meters.

3. The rotation directions of the two spiral blades are opposite, and the material is not easy to be blocked.

4. It can be loaded and unloaded at multiple points in the middle, and the layout is flexible.

5. The conveying capacity is 1.5-2 times that of the single-shaft screw conveyor.

Video

Sludge twin screw conveyor

Clay twin screw conveyor

Twin Screw Conveyor in different designs

-

Horizontal Twin Screw Conveyor

-

Twin Screw Conveyor With Hopper

-

Inclined Twin Screw Conveyor

-

Variable Pitch Twin Screw Conveyor

Structural Design and Analysis

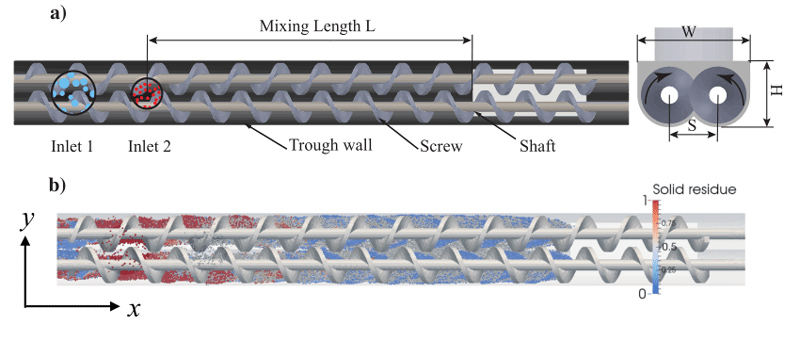

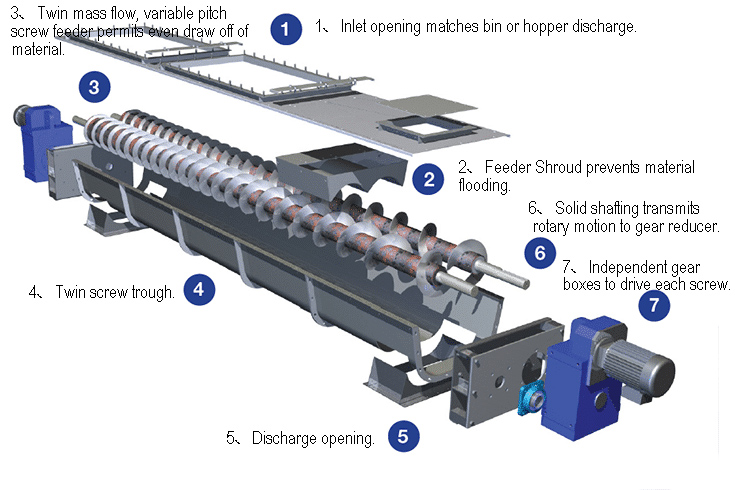

Twin screw conveyor is a special application of screw conveyor. It can be simplified as a combined conveying system of two screw conveyors. The cross-section of the machine is "W"-shaped, and the driving work is usually completed by a single motor.

When designing the screw, the two screws of the Twin screw conveyor have the same delivery direction and opposite rotation directions. This design can complete the self-cleaning work of the two screws at the same time without affecting the material delivery, avoiding material adhesion or clogging . This design also has a stronger material stirring ability, so it has advantages when dealing with poor fluidity materials that are prone to sticking and clogging.

At the same time, it is precisely because of this design that the conveying direction of the Twin screw conveyor is fixed at the beginning. If the screw with the specified conveying direction is forced to be used for reverse conveying, the service life of the Twin screw conveyor will be reduced.

From the perspective of the conveying capacity of the Twin screw conveyor, compared with the single-shaft screw conveyor, the helix angle of the Twin screw conveyor is higher than that of the single helical blade at the same speed, so the blade conveys a larger flow per unit time. Controlling the state of the conveying material remains unchanged, the conveying capacity of the Twin screw conveyor is 1.5-2 times that of the single-shaft screw conveyor.

Technical Parameters

| Specification | Technical performance | Drive | Drive | Weight (kg) | |||

| Diameter | Length (m) | Output (t/h> | Speed (min) | Reducer | Electric motor | ||

| Model | Speed ratio | Power(kw) | |||||

| U 200 | -10 | 9 | 60 | ZQ250 | 23.34 | 1.1 | 726 |

| U 200 | -20 | 9 | 60 | ZQ250 | 23.34 | 1.5 | 1258 |

| U 250 | -10 | 15.6 | 60 | ZQ250 | 23.34 | 2.2 | 960 |

| U 250 | -20 | 15.6 | 60 | ZQ250 | 23.34 | 3 | 1750 |

| U 300 | -10 | 21.2 | 60 | ZQ350 | 23.34 | 3 | 1373 |

| U 300 | -20 | 21.2 | 60 | ZQ350 | 23.34 | 4 | 2346 |

| U 400 | -10 | 51 | 60 | ZQ400 | 23.34 | 5.5 | 1911 |

| U 400 | -20 | 51 | 60 | ZQ500 | 23.34 | 11 | 2049 |

| U 500 | -10 | 87.5 | 60 | ZQ400 | 23.34 | 7.5 | 2381 |

| U 500 | -20 | 87.5 | 60 | ZQ650 | 23.34 | 18.5 | 5389 |

| U 600 | -10 | 134.2 | 45 | ZQ750 | 23.34 | 22 | 3880 |

| U 600 | -10 | 134.2 | 45 | ZQ850 | 23.34 | 55 | 7090 |

The twin screw conveyors produced by Dahan Company are available in various models, and we can also customize them according to your needs.

Application

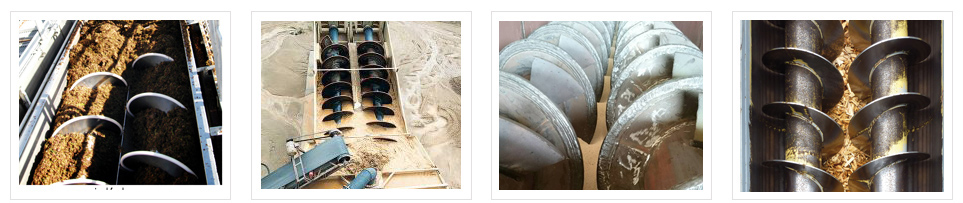

Twin screw conveyors can be used for free-flowing powders and fine particles, but they are ideal for feeding difficult materials such as pigments, sticky, bridging or overflowing powders, fibers and fiberglass.

-

Twin Screw Conveyor for environmental protection

-

4-axis Screw Conveyor conveying wood chips

-

Application of Twin Screw Conveyor in Sewage Treatment

-

Twin Screw Conveyor conveys sludge

-

Two Twin Screw Conveyors with mixers for waste disposal

-

flour auger conveyor site

Factory service

Dahan Machinery is a Twin Screw Conveyor manufacturer from China with 15 years of production and operation experience. The product is guaranteed to be delivered within 48 hours, the drawings for special designs are produced within 72 hours, the machine is sold for 1 year free maintenance, and the product quality problem is unconditionally returned within 7 days.

Dahan Machinery has a modern industrial plant of 10,000 square meters, as well as professional production equipment and design and production personnel, focusing on solving various transportation and lifting problems.

How to choose the right Twin Screw Conveyor?

Some selection tips from manufacturers:

1. What bulk materials need to be transported? What is their material and state?

2. How much conveying capacity do you need per hour and what is your feed rate?

3. What is the height of the material conveying to the next process and the distance you expect?

4. What are the design conditions for Twin Screw Conveyor materials, feeding and discharging conditions, working temperature, and the size of the space reserved in the factory?

We provide you with professional selection guidance, machine design and thoughtful after-sales service. Consult now for more information.